2025 AIChE Annual Meeting

(522h) Optimizing Oxygen Modulation for Fast Surface Cleaning during Dynamic Methane Activation

Authors

Andrew Teixeira - Presenter, Worcester Polytechnic Institute

Fatou Baka Diop, Worcester Polytechnic Institute

Felipe de Faria Teixeira, Worcester Polytechnic Institute

Cameron Armstrong, Worcester Polytechnic Institute

Geoffrey Tompsett, Worcester Polytechnic Institute

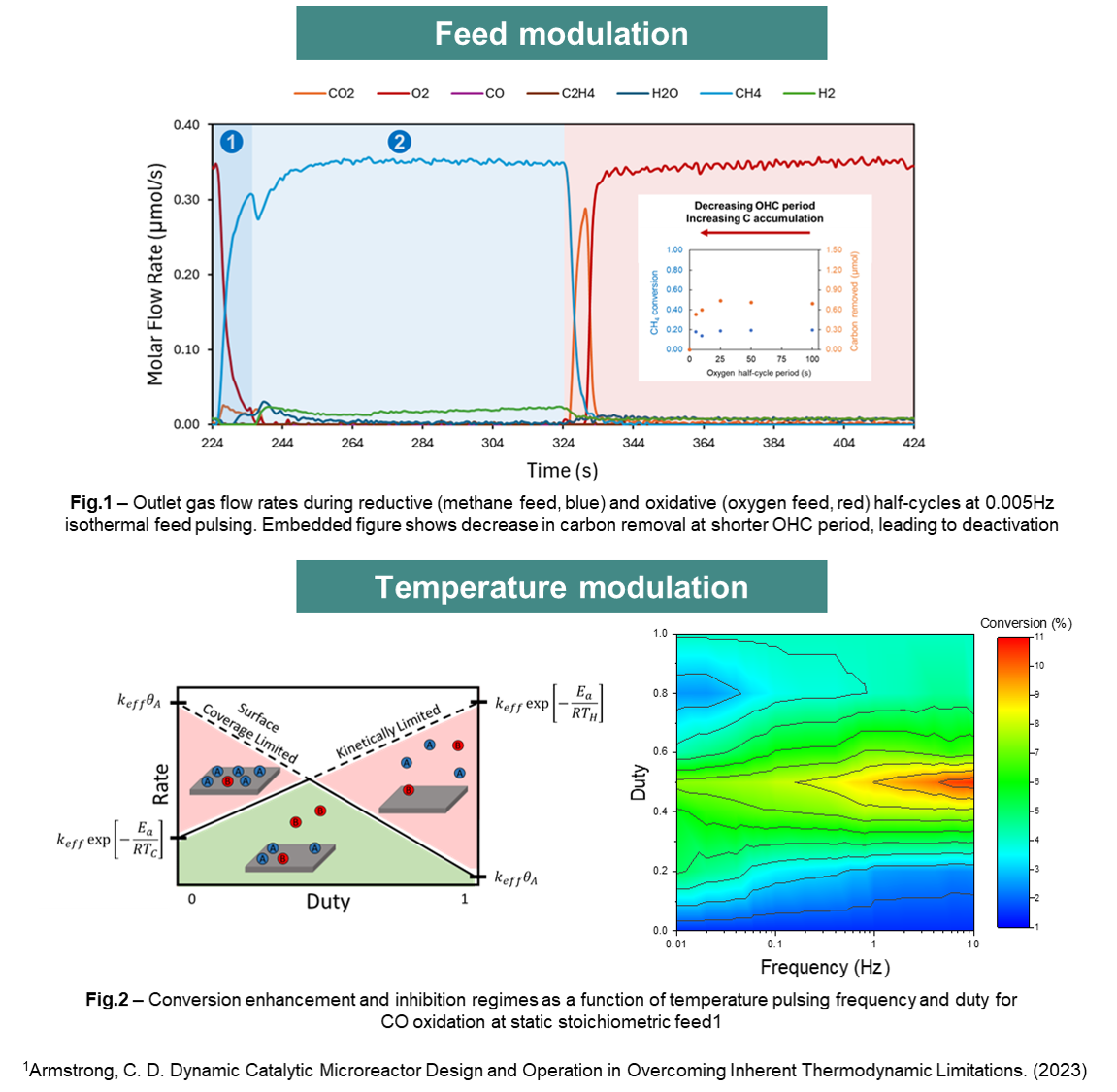

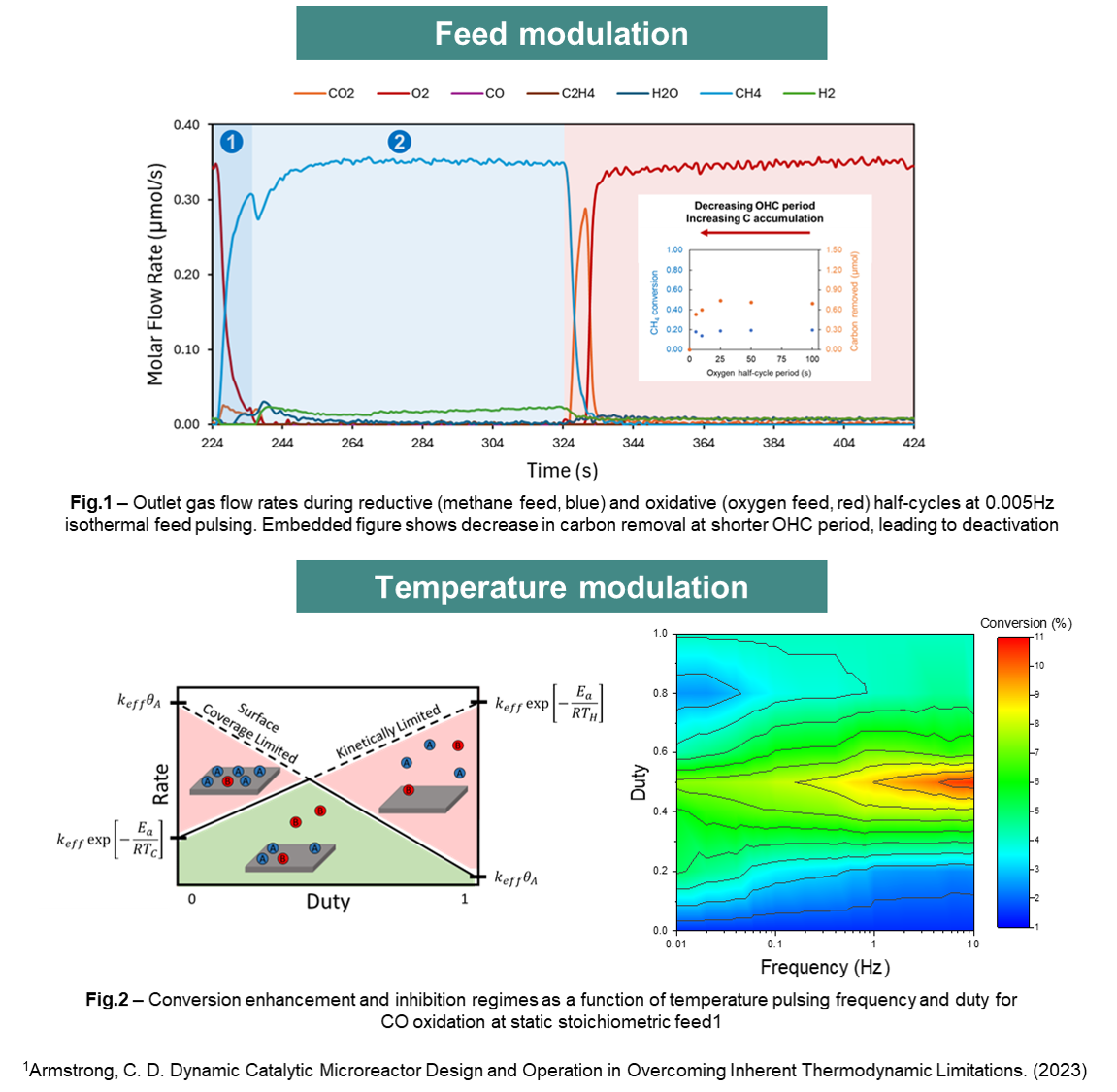

Innovation in microreactors enables small-footprint distributed manufacturing and provides opportunities to relax assumptions conventionally applied to large scale reactors – namely steady state operation. Such concepts enable forced periodic change of process inputs like temperature or reactant concentration to enhance performance beyond thermodynamic limits. In contrast with reaction and catalyst regeneration cycles in large reactors, dynamic operation in microreactors provides significantly shorter length- and-timescales for surface cleaning before deactivation at kinetic timescales and tunable reactivity. This work presents two microreactor platforms designed to optimize oxygen surface coverage through feed and temperature transients to inhibit surface poisoning. Feed modulation was achieved in a 250-micron diameter glass capillary wash-coated with Pd/Al2O3 with up to 10-millisecond gas pulsing. During dynamic methane oxidation at minutes-timescales, the oxidative half-cycle (OHC) replenishes surface oxygen sites, then cleans off carbonaceous species that deactivate the catalyst at increasingly short pulses (fig1). The reductive half-cycle has distinct quasi-steady state regions: a short, high oxygen coverage region favoring total oxidation, followed by oxygen-deficient regions dominated by partial oxidation to hydrogen but limited at long timescales by the lower activity of metallic Pd and carbon accumulation. Optimal surface transients can provide (1) sufficient coverage for oxygen-assisted methane activation and surface cleaning and (2) lean conditions to promote hydrogen production. Furthermore, shorter pulses at frequencies above 0.01Hz outperforms static operation as the surface saturation limit is not reached and non-equilibrium coverages increase conversion at equal OHC/RHC periods while preventing deactivation. During carbon monoxide oxidation in the temperature-modulated reactor1, the conversion limit at low duty suggests a more pronounced effect of CO poisoning while the optimal duty of 0.5 balances high reactant coverage at low temperature to overcome kinetic limitations and surface cleaning with fast reaction/desorption (fig2). Similarly to feed modulation, increasing frequency minimizes coverage limitations, leading to rate-enhancing non-equilibrium coverages.