2025 AIChE Annual Meeting

(667g) Optimizing Membrane-Assisted Bio-Alcohol Dehydration Using Computational and Machine Learning Methods

Authors

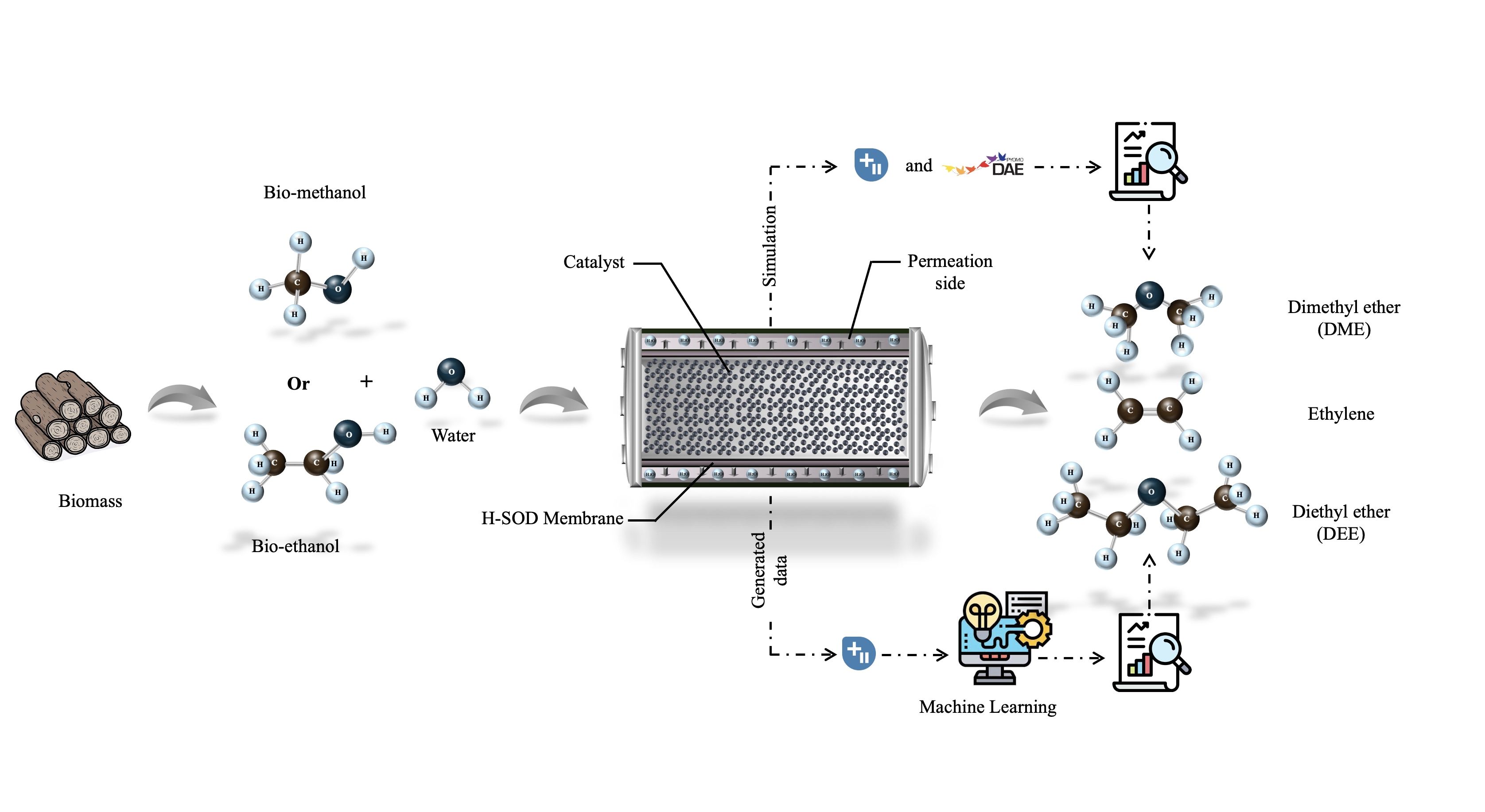

To further enhance process performance, an optimization framework is applied to minimize operating costs while maintaining high conversion and selectivity. Using Pyomo DAE 2, key operating conditions—such as temperature, pressure, and sweep gas flow rate—are systematically optimized to find the most efficient and economical settings. These optimal operating conditions allow for improved reactor performance while reducing overall production expenses.

In addition, machine learning techniques are used to develop predictive models for reactor performance. Physics-Informed Neural Networks (PINNs) 3 and Karush-Kuhn-Tucker-enhanced PINNs (KKT-hPINNs) 4 are trained on high-fidelity simulations performed using Aspen Custom Modeler (ACM)5 simulations. These models provide accurate predictions of reactor behavior while ensuring consistency with physical laws. Results show that KKT-hPINNs outperform traditional neural networks by offering greater accuracy and lower error rates while satisfying mass balances, making them a powerful tool for process modeling. The trained KKT-hPINN model was then transformed into an algebraic model in Pyomo6, 7 to perform optimization. To tackle this, the Optimization & Machine Learning Toolkit (OMLT)8 was used, allowing an automatic translation of the trained neural networks into optimization formulations.

By combining mathematical modeling, process optimization, and machine learning, this study presents an advanced yet practical approach to improving reactor efficiency and reducing costs. The optimized membrane reactor produces 35.5% more biofuel (such as Dimethyl ether) and yields 15% higher profit than the fixed-bed reactor by removing water more effectively. Additionally, KKT-hPINNs outperform standard neural networks by reducing RMSE by over two orders of magnitude and enforcing physical constraints, resulting in significantly more accurate and reliable predictions. These findings highlight the potential of artificial intelligence and optimization strategies to enable more sustainable and cost-effective biofuel production processes.

Reference:

1. Bakhtyari, A., Bardool, R., Rahimpour, M. R., Mofarahi, M. & Lee, C. H. Performance analysis and artificial intelligence modeling for enhanced hydrogen production by catalytic bio-alcohol reforming in a membrane-assisted reactor. Chem Eng Sci 268, 118432 (2023).

2. Nicholson, B., Siirola, J. D., Watson, J.-P., Zavala, V. M. & Biegler, L. T. Pyomo.DAE: A modeling and automatic discretization framework for optimization with differential and algebraic equations. Math Program Comput 10, 187–223 (2018).

3. Karniadakis, G. E. et al. Physics-informed machine learning. Nature Reviews Physics vol. 3 422–440 Preprint at (2021).

4. Chen, H., Flores, G. E. C. & Li, C. Physics-informed neural networks with hard linear equality constraints. Comput Chem Eng 189, 108764 (2024).

5. Aspen Technology, Inc. Aspen Custom Modeler. Preprint at (2021).

6. Bynum, M. L. et al. Pyomo—Optimization Modeling in Python. Springer International Publishing 67 (2021).

7. Hart, W. E., Watson, J.-P. & Woodruff, D. L. Pyomo: Modeling and solving mathematical programs in Python. Math. Program. Comput. 3, 219–260 (2011).

8. Ceccon, F., Jalving, J., Haddad, J., Thebelt, A., Tsay, C., Laird, C. D. & Misener, R. OMLT: Optimization & Machine Learning Toolkit. J. Mach. Learn. Res. 23, 349, 1–8 (2022).