2025 AIChE Annual Meeting

(309a) Optimizing Catholyte Flow-Field Geometries to Enable More Selective and Stable CO2RR Flow-Based Electrolyzers – a Customizable Approach

Authors

Often overlooked, catholyte flow plate geometry, the portion of an electrolyzer that introduces catholyte into the cell, and catholyte fluid velocity have been shown to influence parameters integral to the performance of CO2RR systems. Variables including velocity and pressure distribution, localized pH differences, and air bubble trapping at the cathode surface are all influenced by changes in the plate’s geometry, which in turn have a direct influence on reactor longevity and efficiency.

According to previously published literature, uniformity of catholyte flow across the cathode is vital to enhancing longevity and efficiency. For example, the lifespan of gas diffusion electrode (GDE) based CO2RR reactors is often cut short due to flooding in the gas chamber, a phenomenon in part due to uneven-pressure distribution across the GDL. Uniform catholyte flow can help establish a more consistent boundary layer at the cathode to prevent such discrepancies between the pressure applied on the gaseous side and the catholyte side. Additionally, there exists a direct correlation between uniform catholyte velocity distribution and faradaic efficiencies towards C2+ products in GDE electrolyzers, largely due to the local chemical reaction environment (pH) and removal of bubbles from the surface.

Despite this, flow plate geometry is rarely reported on in the field of CO2 electrolysis, resulting in reduced replicability between labs and potentially less efficient systems towards the production of C2+ products.

To address this issue, we establish a simple method of identifying the optimal geometry and flowrate for each unique flow-based system to establish uniform catholyte flow across the cathode and improve C2+ product faradaic efficiency. This method includes 3 steps: design, simulation, and benchtop validation.

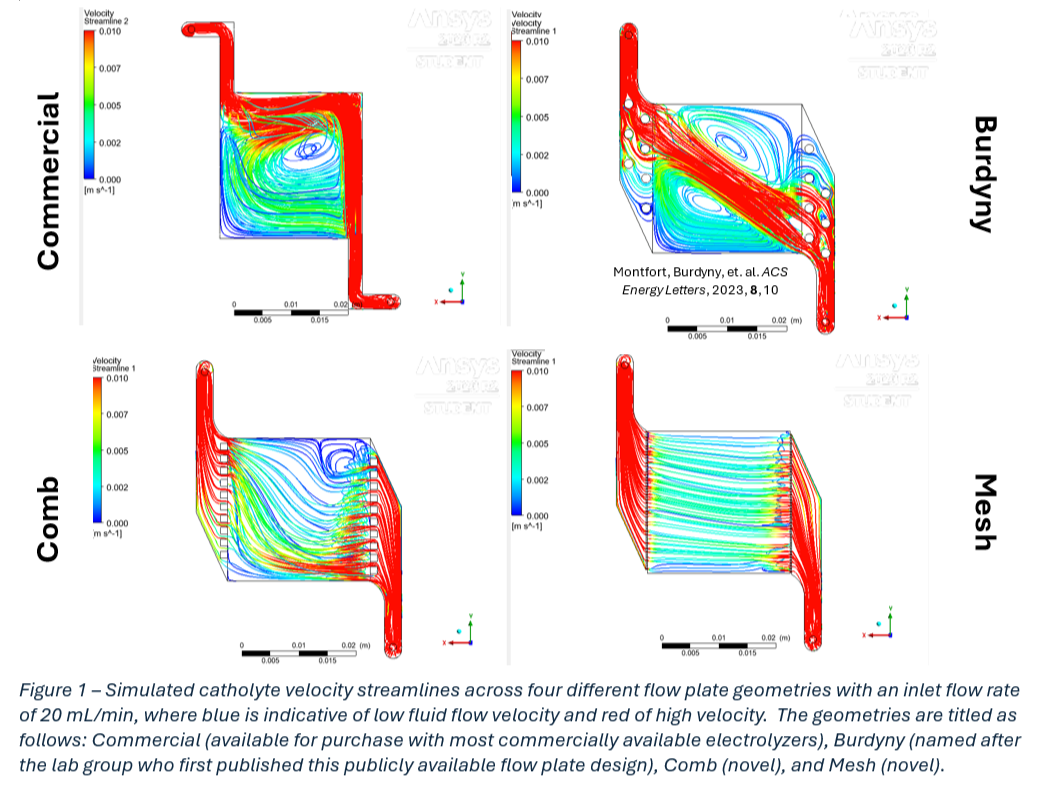

Here we investigate four different catholyte flow plate geometries and analyze their impact on catholyte flow uniformity at varying inlet flow rates. Simulations of fluid flow through each geometry were conducted using ANSYS FLUENT to determine the optimal flow conditions necessary for consistent catholyte uniformity. Simulations were then experimentally validated with 3D-printable catholyte flow plates due to their low cost, accessibility, and ability to be customized.

By offering a method to ensure the most optimal geometry and flowrate are being used for each electrolyzer application, we offer the community control over systemic variables in addition to a potential increase in electrolyzer efficiency towards C2+ products. Achieving these two improvements is an important steppingstone on the way to introduce CO2 electroreduction on scale.