2025 AIChE Annual Meeting

(512b) From Ocean to Package: Scalable Seaweed-Based Coatings for Enhanced Paper Packaging Performance

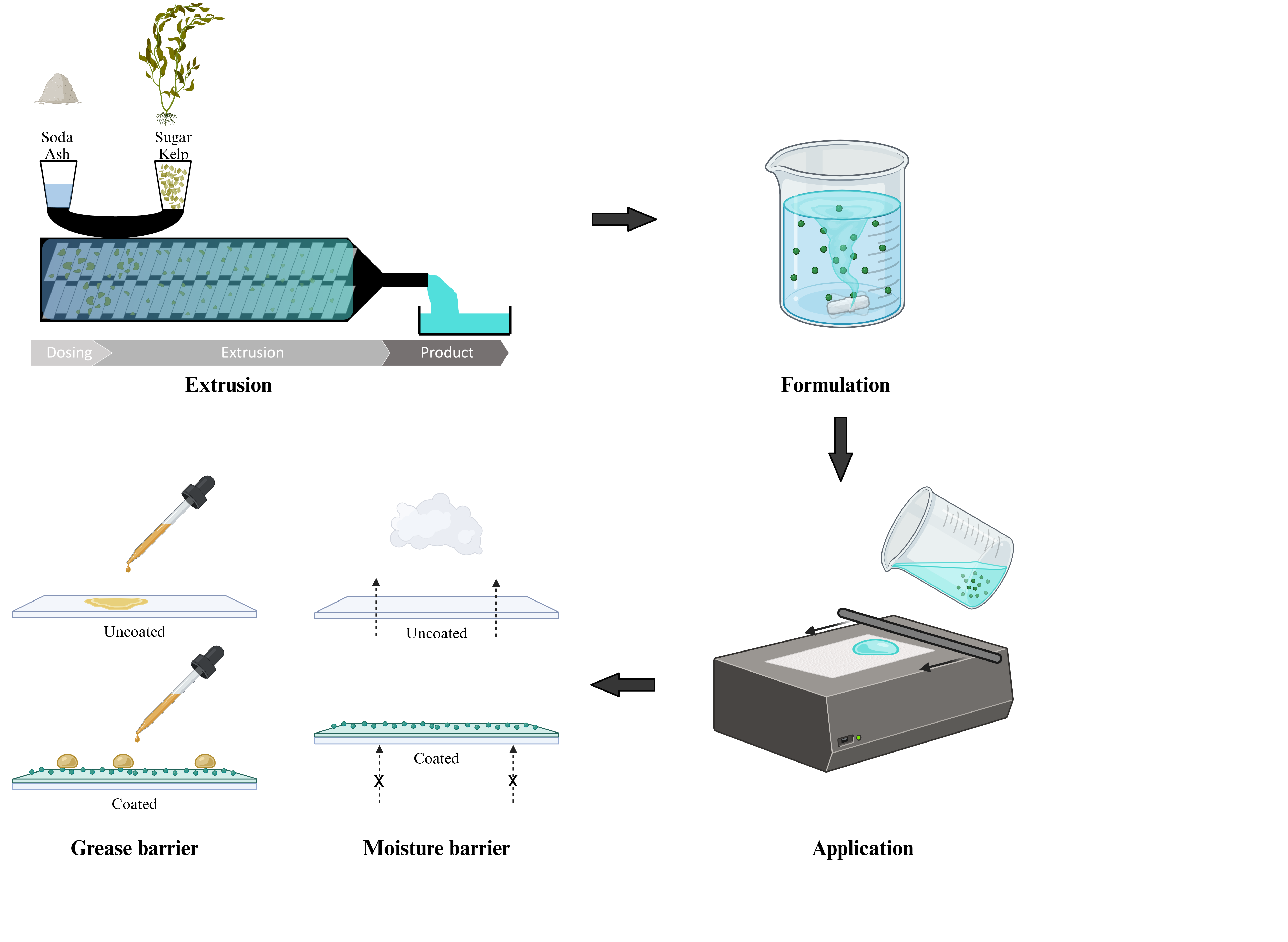

In this work, we demonstrate a scalable, sustainable process to convert raw seaweed biomass directly into a high-performance, ocean-compostable, PFAS(per- and polyfluoroalkyl substances)-freebarrier coating for paper-based packaging. At the core of this innovation is a Reactive Extrusion Extraction (REE) process, adapted to extract functional polysaccharides from sugar kelp in a one-pot, solvent-free operation. Unlike conventional solvent-based extraction methods that require multiple steps, high energy input, and toxic reagents (e.g., sulfuric acid), REE allows continuous processing of wet seaweed slurry, drastically reducing water, energy, and chemical usage while enabling direct formulation of a coat-ready slurry. This process inherently aligns with green manufacturing principles and offers a commercially viable route to valorize a marine resource that is both abundant and climate-resilient.

The extruded coating, applied to paper substrates, forms a uniform, microplastic-free barrier coating that improves both moisture and grease resistance. The coating achieved a 76% reduction in Water Vapor Transmission Rate (WVTR), from 319 to 77 g/m²/day under tropical conditions (38 °C, 90% RH, ASTM F1249). It also outperformed conventional grease-resistant tissue (123 g/m²/day) by 37%, demonstrating clear potential to meet the stringent performance criteria of food packaging. The coating also significantly improves grease repellency, increasing the contact angle against castor oil from 17.2° to 49.5°, indicating enhanced surface resistance to oily contaminants. In food-contact trials using real greasy foods such as chicken nuggets and fries, the coated paper effectively prevented grease absorption.

The coating also prevents oil migration by leveraging the hydrophilic–lipophobic character of seaweed-derived polysaccharides, primarily alginate, which forms a dense, gel-like matrix upon drying. This matrix acts as a diffusion barrier to non-polar substances like oils. Importantly, this functionality is achieved without the use of fluorinated chemicals or synthetic additives, making it both safe and environmentally responsible.

Structurally, the seaweed biomass comprises a natural integration of alginate and cellulose, where alginate serves as the matrix-forming polysaccharide and cellulose offers reinforcement. During extrusion, the shear and thermal conditions facilitate partial fibrillation of cellulose, promoting the in-situ generation of micro- to nano-scale cellulose. This micro-fibrillated cellulose not only enhances mechanical strength and film cohesion but also contributes to the tortuous path effect, reducing the permeability of the coating to water vapor and grease by extending the diffusion path of molecules.

The composite structure of entangled polysaccharide chains and embedded microcellulose fibers creates a coherent, flexible, and low-porosity layer, capable of adhering uniformly to paper substrates while providing robust resistance to oil penetration and moisture transmission. This synergistic interplay between seaweed polysaccharide chemistry and native fibrous morphology allows the coating to exhibit both functional performance and material sustainability, making it well-suited for fiber-based packaging applications that demand microplastic-free, grease-resistant, and compostable solutions. The application achieves this barrier enhancement with less than 10 gsm of added material, retaining the lightweight advantage critical to cost-sensitive and process-compatible packaging formats.

Together, these contributions present a paper coating that advances not only barrier performance and environmental safety but also the scalability and industrial readiness required for real-world impact. This work demonstrates a smart biorefinery strategy that combines seaweed chemistry, reactive extrusion processing, and end-of-life compostability to create a commercially viable, PFAS-free alternative for paper coatings. The integration of marine biomass valorization with practical barrier functionality opens new opportunities for decarbonizing the packaging sector while supporting coastal economies and sustainable aquaculture. This work lays the foundation for future studies on process-structure-property relationships in seaweed-based coatings, as well as broader exploration of marine biomass composites for scalable, smart, and circular material systems.