2025 AIChE Annual Meeting

(552b) Observation and Characterization of Multiple Lamellar Stacks in Homogeneous, Semicrystalline Random Copolymers

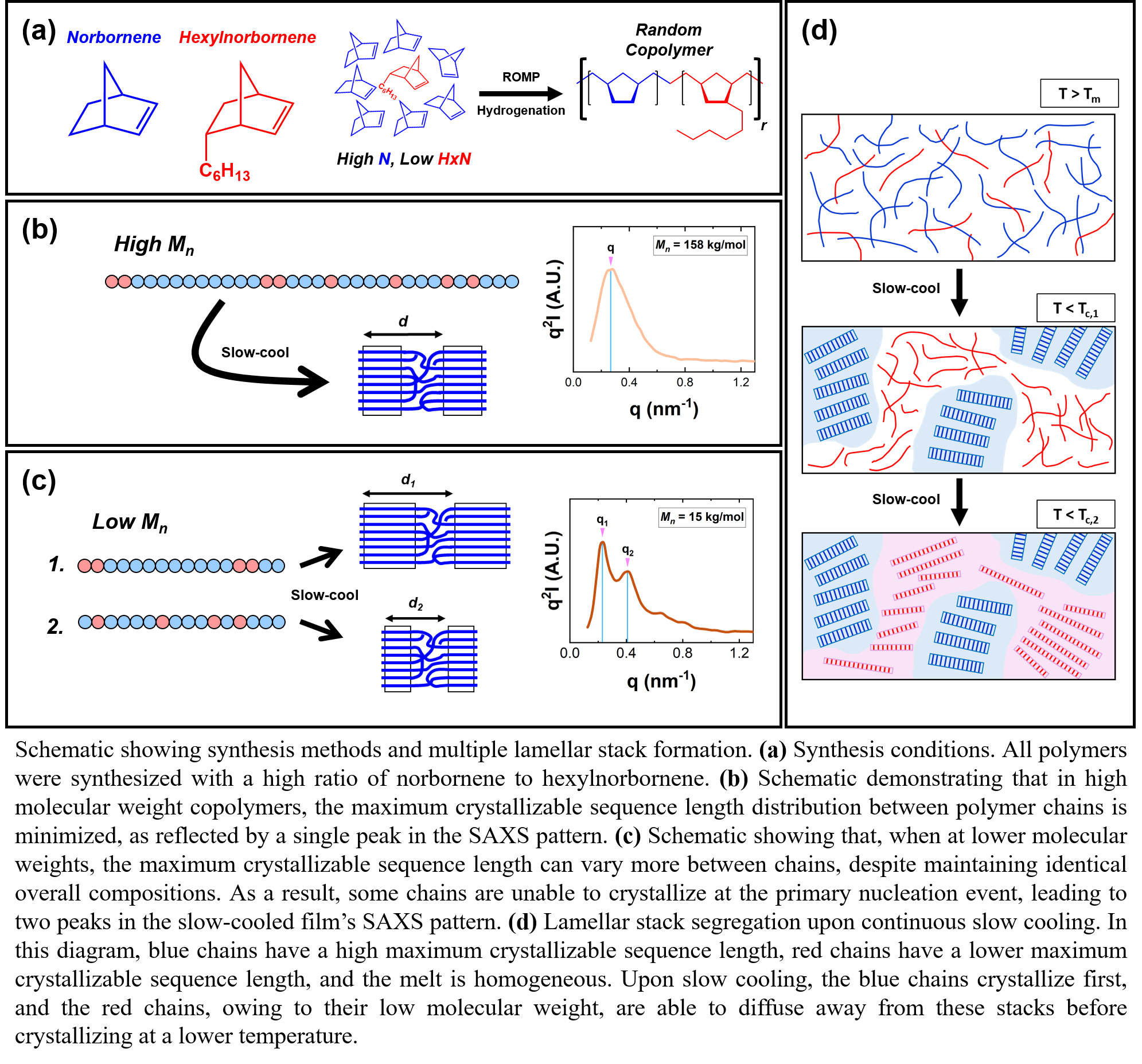

In this work, we observe the unexpected presence of two distinct types of lamellar stack in homogeneous random copolymers of norbornene and hexylnorbornene (hPNrH) after hydrogenation and slow cooling (less than 1 °C/min) from the melt. All copolymers were polymerized via ring-opening metathesis polymerization with a Schrock-type catalyst, terminated before complete conversion to keep the down-chain gradient within 10% relative to the overall composition, and fully hydrogenated, so such an observation was surprising. The distinct stacks were first observed as secondary peaks in the room-temperature small-angle X-ray scattering (SAXS) patterns that did not form a 2:1 angular (q) ratio with the primary lamellar peak. Hot-stage SAXS revealed that the higher-q feature, whether it appeared as a resolved peak or a shoulder protruding from the main peak, disappeared prior to the melting temperature, indicating it represents an entirely separate lamellar stack with a smaller domain spacing (d) and crystal thickness (Lc). Melting endotherms of these copolymers, on the other hand, do not exhibit a clear secondary peak, only a broad shoulder on the low-temperature side of the main peak.

The relationship between the intensity of the secondary lamellar peaks and both molecular weight and branch content would indicate that molecular parameters of the bulk material play a role in secondary stack formation. This was further investigated by in-situ thermal fractionation of each copolymer. The successive self-annealing thermal fractionation (SSATF) technique was utilized, where the material was successively heated up to partially melt the crystallites, annealed, and cooled back down to room temperature, repeating each step for progressively lower annealing temperatures. Within each polymer series (as defined by hexylnorbornene mole percent), decreasing molecular weight corresponded with an increase in the number of melting peaks upon reheating the thermally-fractionated samples. This was quantified by taking the ratio of the melting enthalpy of the largest peak (ΔHm,maj) to the overall melting enthalpy (ΔHm,tot). The smaller this ratio, the greater the fraction of polymer that crystallized into thinner crystals. Such a correlation between molecular weight and ΔHm,maj/ΔHm,tot provides a key insight for how these multiple stacks form, but to fully appreciate this, one needs to take a step back and discuss the characteristics of the polymers being studied.

It cannot be emphasized enough that these copolymers are synthesized via a random, living polymerization technique. While the reactivity ratios of norbornene and hexylnorbornene are not unity, the reaction is terminated at a point where the hexylnorbornene content along the entire chain varies by ±10% (e.g., 5.5-4.5 mol% for 5 mol% average). Each chain should thus be compositionally identical with minimal compositional gradients from the start to the end. At high molecular weights, each individual chain is so long that the maximum crystallizable sequence length is sufficiently long to crystallize into the primary lamellar stacks. At lower molecular weights, including for many of the hPNrH copolymers studied herein, the chain-to-chain variance in the longest crystallizable sequence length increases. As a result, some chains are unable to crystallize with the primary lamellae, and under the time scales of slow cooling, they diffuse away from the primary lamellae before crystallizing at a lower temperature into secondary stacks.

Such a heterogeneous morphology in what is otherwise a homogeneous copolymer should inevitably affect the mechanical properties of the bulk material. For this work, emphasis was placed on the tensile modulus and ductility. The trend of tensile modulus with crystallinity for these copolymers was found to be identical regardless of whether the material was quenched or slow-cooled from the melt, suggesting that the effect of the multiple stacks on the bulk modulus is additive. On the other hand, the presence of multiple stacks makes predicting ductility more complex. Similarly to previous work from our group, the Huang-Brown model was used to calculate tie molecule (TM) fraction for all polymers. To briefly summarize, the Huang-Brown model calculates the probability that a chain with a certain end-to-end distance will form a TM, which is effectively the bulk TM fraction (Pavg). Pavg is heavily dependent on the dimensions of the lamellar stack (d and Lc); the stacks with lower d and Lc possess a greater Pavg than the stacks with a greater d and Lc. This begs the question whether just one or both types of stacks need to resist brittle fracture for the bulk sample to demonstrate ductility, requiring consideration of how the yield stress of each type of stack differs. Since these hPNrH copolymers do not crystallize homogeneously, each type of stack will exhibit different mechanical properties. Yield stress in particular should be different between each type of stack, with the secondary stacks featuring a lower yield stress as a result of their thinner lamellae. This would imply the secondary stacks yield first, and if they resist brittle fracture and form a stable fibril, the entire bulk sample is anticipated to exhibit ductility. This implication is confirmed by looking at the relationship between TM fraction at the brittle-ductile transition (PBDT) and Lc for the copolymers both slow-cooled and quenched from the melt: the TM fraction for the shorter-period stacks collapses with the PBDT relationship for the quenched copolymers.

The observation of multiple lamellar stacks in these slow-cooled hPNrH copolymers demonstrates how idealized models can no longer hold true in specific circumstances. In this work, we establish that molecular weight is intrinsically tied to the ability of a random copolymer to crystallize into homogeneous lamellar stacks. The lower the molecular weight of the sample, the greater fraction of chains are unable to crystallize at the primary nucleation event, diffuse away from the main stacks, and crystallize at a lower temperature with a much lower d and Lc. While how these stacks impact the tensile modulus and ductility was studied, it is anticipated that other material properties would also be affected. In particular, future work will investigate whether it is possible to further manipulate the solid-state dimensions (d and Lc) of each type of stack, allowing for additional control over bulk properties.