2025 AIChE Annual Meeting

(193b) Numerical Modeling of Hydrogen Generation from Metal Hydride in a Millimeter-Scale Reactor

Authors

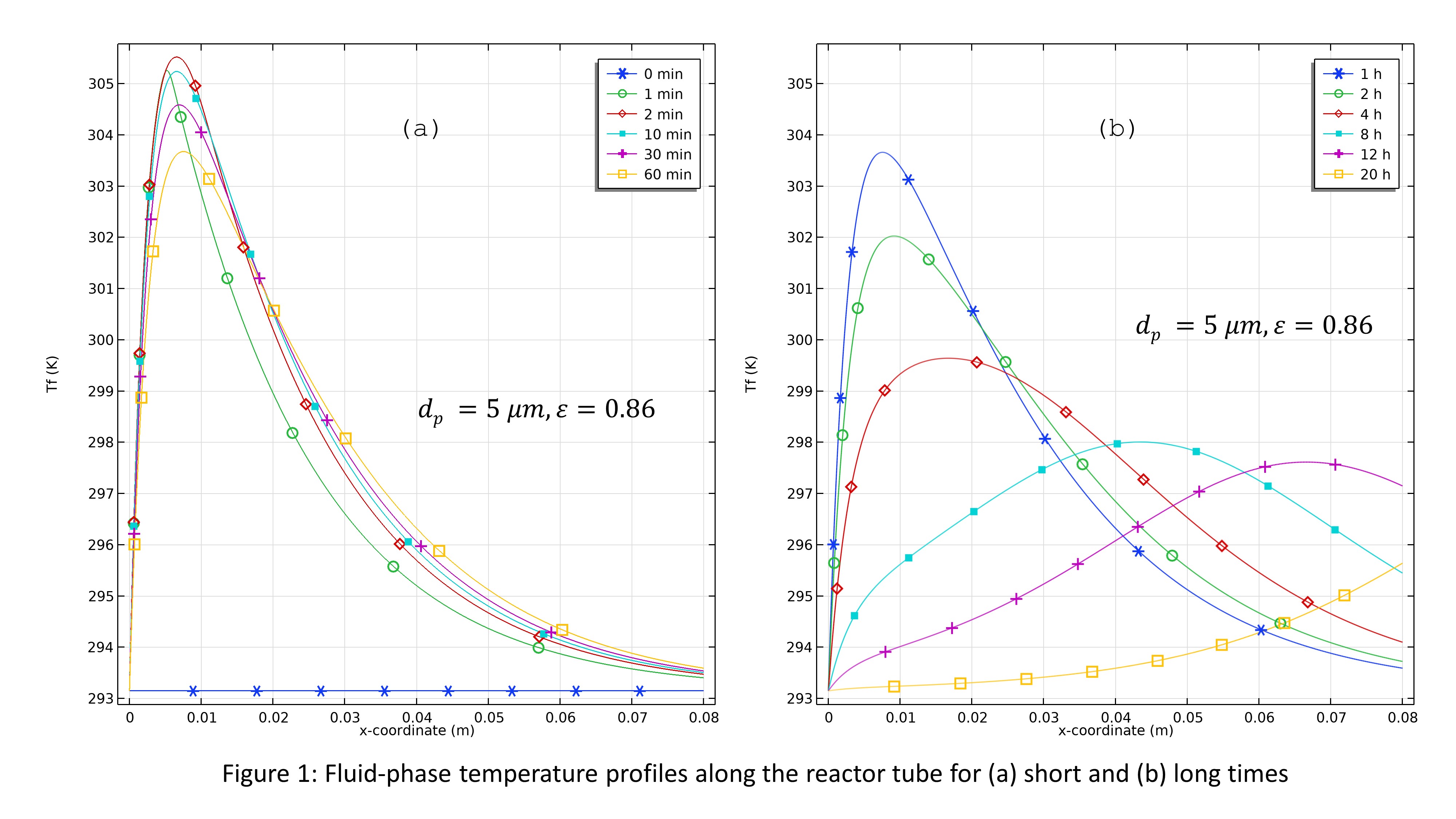

To address the practical use of LAH for hydrogen generation, we developed an unsteady 1D heterogeneous model of a millimeter-scale fixed bed reactor, using kinetics derived from literature experiments in a batch reactor for LAH hydrolysis2 along with a simplified lumped particle sub-model, justified by the small size of the particles (< 50 μm). The model has species balances for H2O and H2 and energy balances, in the fluid and particle phases, LAH in the particle phase, and equations for pressure drop and change in total molar flow. The equations were solved in conservation form by the finite element method. The reactor tube dimensions were approximately 0.08 m long, 0.023 m in diameter with wall cooling at 293.15 K. The base case from literature was 5 μm particles and void fraction ε = 0.86.

The resulting species profiles show the progression of the reaction front along the tube. Figure 1 shows the development of the temperature profile with time, for base case conditions. Parametric studies will be presented to show the effect of particle-scale configurations (size, void fraction) and tube-scale configurations (flow velocity, tube diameter) on the hydrogen production rate and the temperature rise.

References

- Aiello R, Sharp JH, Matthews MA. Production of hydrogen from chemical hydrides via hydrolysis with steam. J. Hydrogen Energy. 24 (1999) 1123-30.

- Eickhoff S. The effects of hydride chemistry, particle size, and void fraction on micro fuel cell performance. Power Sources. 243 (2023) 562-8.