2025 AIChE Annual Meeting

(178c) Numerical Analysis for the Effect of Mixer Shapes on Thermal Flow Behavior in a Flow-Type Supercritical Hydrothermal Mixer

Numerical simulations of three-dimensional thermal flow fields in a flow-type mixer were carried out using a computational fluid dynamics software, ANSYS FLUENT. A T-junction with an inner diameter of 2.3 mm was used as a mixer. The conventional mixer was assembled by connecting tubes with an outer diameter of 1/8 inch and wall thickness of 0.71 mm in a T-junction. The proposed mixer was assembled by inserting a narrower tube with an outer diameter of 1/16 inch and wall thickness of 0.30 mm into the T-junction from the side. The rest parts of the proposed mixer are the same as in the conventional mixer. The insertion length of the narrower tube was determined based on the T-junction radius, and simulations were performed with various insertion positions of tube. Supercritical water at 660 K was supplied from the top, and room-temperature water at 294 K was supplied from the side at various flow rates. Flow and temperature fields were analyzed at a constant pressure of 25 MPa.

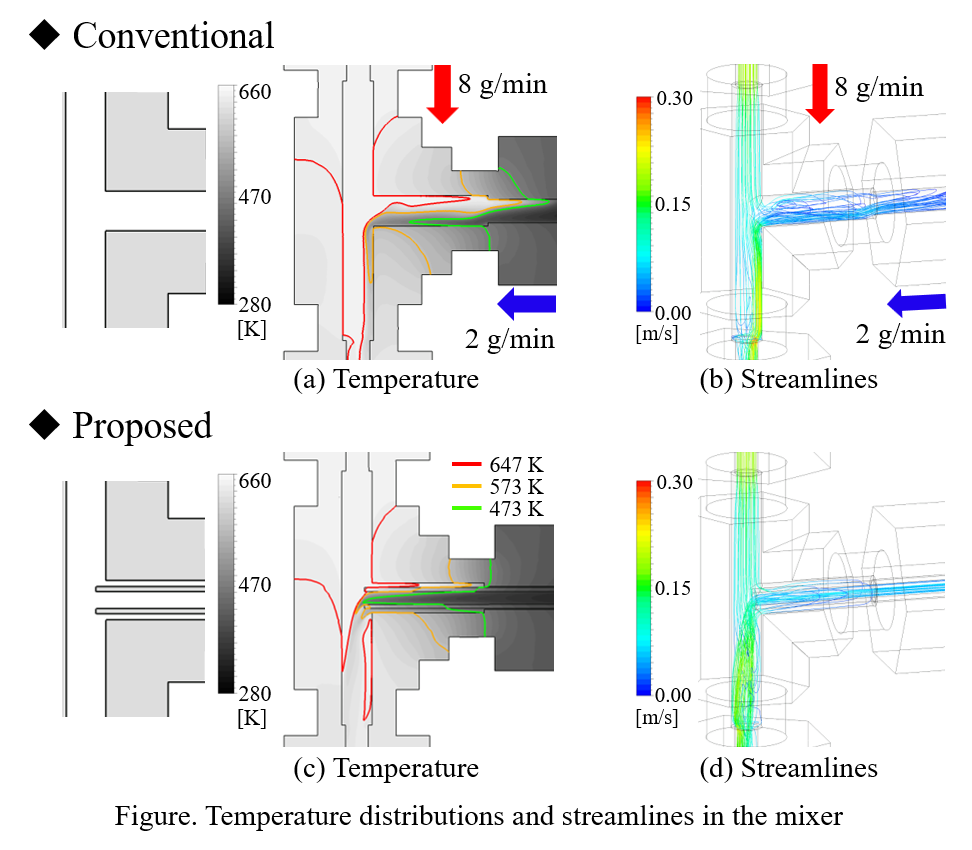

The figure shows the temperature distributions and streamlines in the conventional mixer and the proposed mixer when the flow rates of the supercritical water (QSC) and room-temperature water (QRT) were QSC = 8.0 g/min and QRT = 2.0 g/min. The red line in the temperature distributions is the isotherm of 647 K, which is the critical temperature of water, as an indication for the high-temperature region. In the conventional mixer as shown in Fig. (a), the stream of supercritical water flowing down through the vertical tube penetrated the horizontal tube. Consequently, the high-temperature region was widely distributed. In the proposed mixer as shown in Fig. (c), the supercritical water did not penetrate the inserted narrower tube, and the high-temperature region was not distributed widely. This is due to the increased inertial force of the room-temperature water stream caused by the use of a narrower tube. At the vertical tube after mixing, the high-temperature region was narrowly distributed in the proposed mixer. In the conventional mixer as shown in Fig. (b), a circulation flow was formed in the upper part of the horizontal tube. This is because the stream of supercritical water flowing down through the vertical tube penetrated the horizontal tube by buoyancy owing to the difference in density between the supercritical water and the room-temperature water. In the proposed mixer as shown in Fig. (d), the stream of supercritical water flowing down through the vertical tube did not penetrate the side tube. In addition, a stagnant region of the flow existed on the vertical tube after mixing in each mixer. In the proposed mixer, a narrower stagnant flow was formed, and it might cause the formation of a uniform temperature distribution.

In this work, numerical simulations for the flow-type supercritical hydrothermal mixer were carried out to reveal the effect of mixer shapes on the thermal flow behavior. In the proposed mixer, the high-temperature region above the critical temperature was narrowly distributed, and no circulation flow was formed in the horizontal tube. The result shows that the proposed mixer quickly mixes the supercritical water and room-temperature water. Therefore, the proposed mixer is expected to produce nanoparticles with narrower size distribution by the precise control of thermal flow fields.