2025 AIChE Annual Meeting

(376d) Novel Joule Heated Reactor for Electrothermal Integrated Carbon Capture and Utilization

Authors

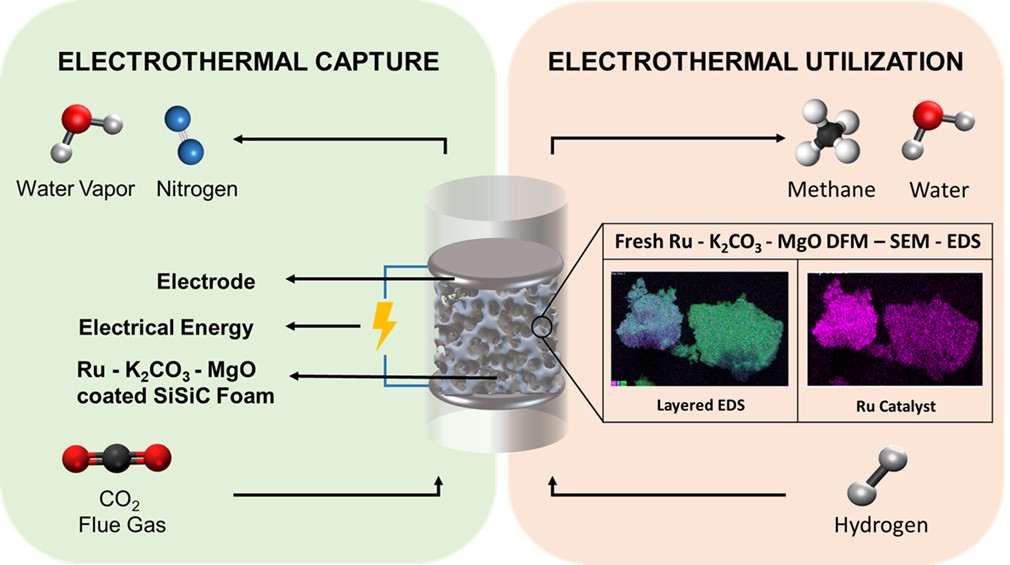

The Ru-K2CO3-MgO DFM with 5% Ru loading was synthesized using a wet impregnation method and characterized through a suite of analytical techniques. X-ray diffraction (XRD) was employed to analyze the phase compositions, Scanning Electron Microscopy with Energy Dispersive Spectroscopy (STEM-EDS) was utilized to confirm the uniform dispersion of Ru, and Brunauer-Emmett-Teller (BET) analysis determined the optimum surface area. Catalytic characterizations were further conducted using Temperature Programmed Reduction (TPR), which identified Ru reduction peaks at 200℃ and 250℃. Temperature Programmed Surface Reaction (TPSR) indicated an optimum methanation temperature of 320℃. A slurry of this Ru-DFM was uniformly coated onto a 30 PPI SiSiC foam to a thickness of 10μm on a 3.5% weight basis. The coating's adhesion, mechanical integrity, and thermal stability were thoroughly evaluated. Additionally, the text discusses challenges such as DFM coating on foam supports, catalyst sintering, and degradation through electrothermal swing operations, providing solutions to these issues.

The DFM-coated foam was utilized in a custom-built stainless-steel reactor, which was resistively heated by two grooved stainless-steel electrodes connected to an AC power supply. The reactor was sealed with stainless steel conflate flanges, featuring three inlets that accommodate feed/product gases, electrical feedthroughs, and thermocouples at each end. A distinct mechanical design integration in the novel E-ICCU reactor enables the separation of sensory equipment from the electrified core, maintaining outer-body temperatures below 60°C to ensure thermal safety. Product gases from the reactor are analyzed using a mass spectrometer connected directly to the system. Prior to operation, the Ru-K2CO3-MgO DFM-coated SiSiC foam underwent pretreatment in a pure helium (He) flow for 30 minutes, followed by a reduction process in a 10% hydrogen (H2, balance He) environment at 500°C for one hour. Carbonation was carried out by resistively heating the foam to 150°C using a 10% CO2 (balance He) flue gas feed, followed by methanation at 320°C using a 20% H2 (balance He) feed. The E-ICCU methanation process achieved a high methane (CH4) selectivity of 98%, with no evidence of carbon deposit formation.

The Joule-heating effect significantly enhanced process efficiency, achieving over 95% in terms of heat management and temperature control, surpassing conventional combustion heating methods. The development of the electrothermal process focused on the rapid tunability of Joule-heating to optimize catalyst coating, electrode geometry, conductive material selection, insulation design, and overall heat management. A one-dimensional gPROMS model was developed using rigorous first-principles to generate mass-energy balance equations and finite element modeling to calculate concentration and temperature profiles within the catalyst-sorbent foam bed. Utilizing experimental data from our novel laboratory-scale electric reactor, we validated the simulated model, which integrates multiple physical phenomena such as diffusion-reaction and conduction. This model offers fundamental insights into the Joule heating of composite materials and facilitates the optimization of Joule heating inputs, reactor geometry, and catalyst loading to maximize energy efficiency and conversion yield.

The innovative E-ICCU reactor can be integrated with a range of existing catalytic processes, facilitating the transition to low-carbon chemical production within the next decade. By minimizing energy consumption through electrification, the E-ICCU process tackles significant hurdles facing the commercialization of ICCU technologies. This distinctive approach enhances the economic feasibility of producing chemicals derived from CO2 and offers a sustainable method for reducing greenhouse gas emissions, surpassing the performance of current technologies.