2025 AIChE Annual Meeting

(114b) Non-Aqueous CO2 Reduction for Economical Multicarbon Products from CO2

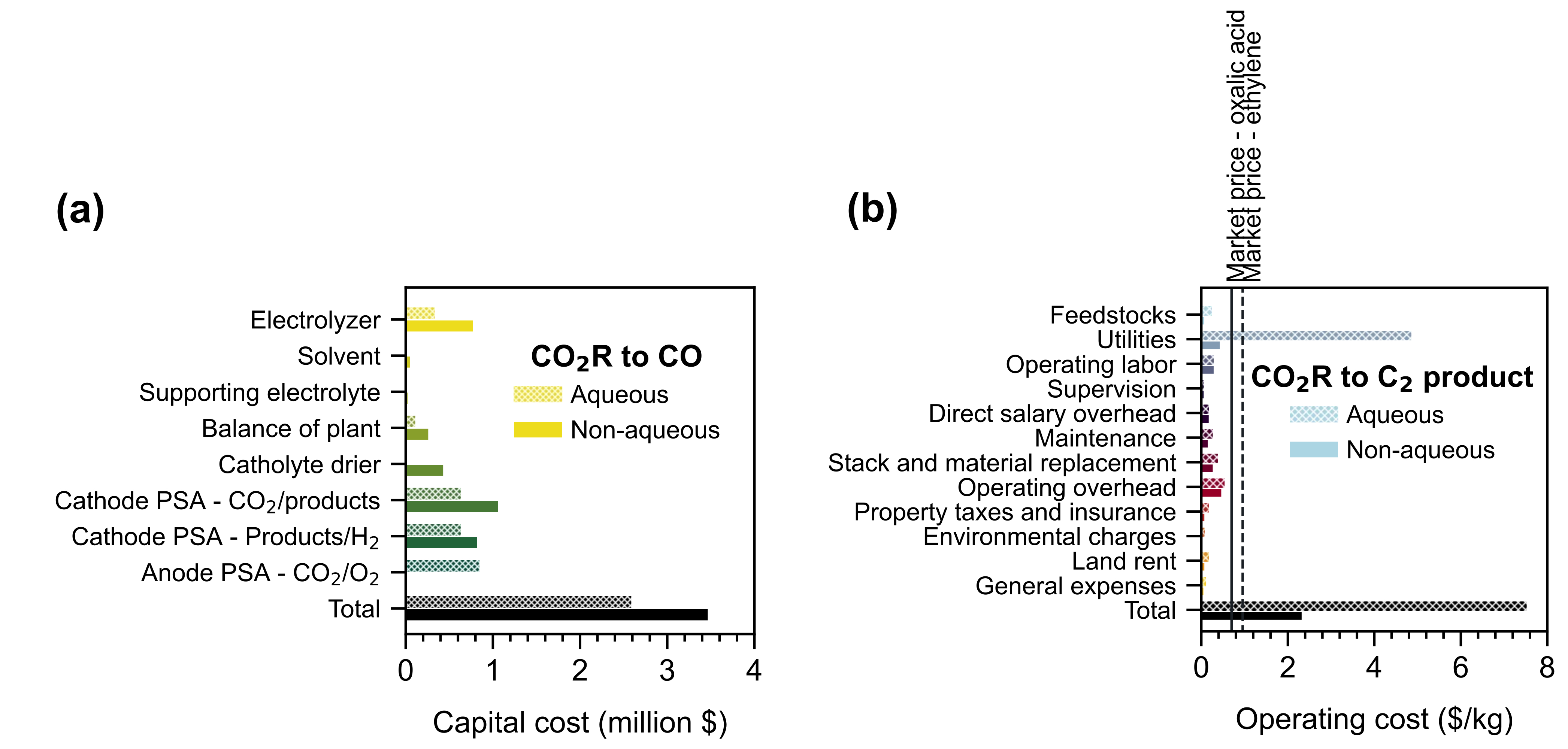

We show that oxalic acid can be produced at $2.87/kg in a small-scale process with minimal technology developments beyond the current state-of-the-art. Commercial-scale CO2R to oxalic acid could reach $1.56/kg with minimal technology improvement, approaching the market price of $0.7 – 2.5/kg. Although liquid-liquid separation adds capital cost, oxalic acid is a more economical product than ethylene on a levelized basis. Its cost competitiveness is driven by its market value and 2-electron reaction pathway. We also present a recommended pathway towards economical CO2R to oxalic acid. Key priorities for achieving cost targets include increased current density, extended cell lifetimes, and optimized flow cell configurations. Additionally, lowering cell resistance by enhancing electrolyte conductivity or reducing catholyte chamber width is crucial. This assessment highlights the immense potential of non-aqueous CO2R, which has been largely overlooked compared to aqueous CO2R.

- Da Cunha, S. C. & Resasco, J. Nat. Commun. 14, 5513 (2023).

- Da Cunha, S. C. & Resasco, J. ACS Energy Lett. 9, 5550–5561 (2024).