2025 AIChE Annual Meeting

(584cb) Nickel-Doped Spent CO Oxidation Catalysts for Sustainable Dry Reforming of Methane: Synthesis, Characterization, and Performance Evaluation

Authors

Nada Abounahia, Qatar Environment and Energy Research Institute, Hamad Bin Khalifa University

Francesco Ferella, Department of Industrial and Computer Engineering and Economics, University of L’Aquila

Nicolò Ippolito, Department of Industrial and Computer Engineering and Economics, University of L’Aquila, L’Aquila, P.le E. Pontieri 1, Monteluco di Roio, 67100 L’Aquila, Italy

Alessandro Sinopoli, Qatar Environment and Energy Research Institute, Hamad Bin Khalifa University, P.O. Box 34410, Qatar Foundation

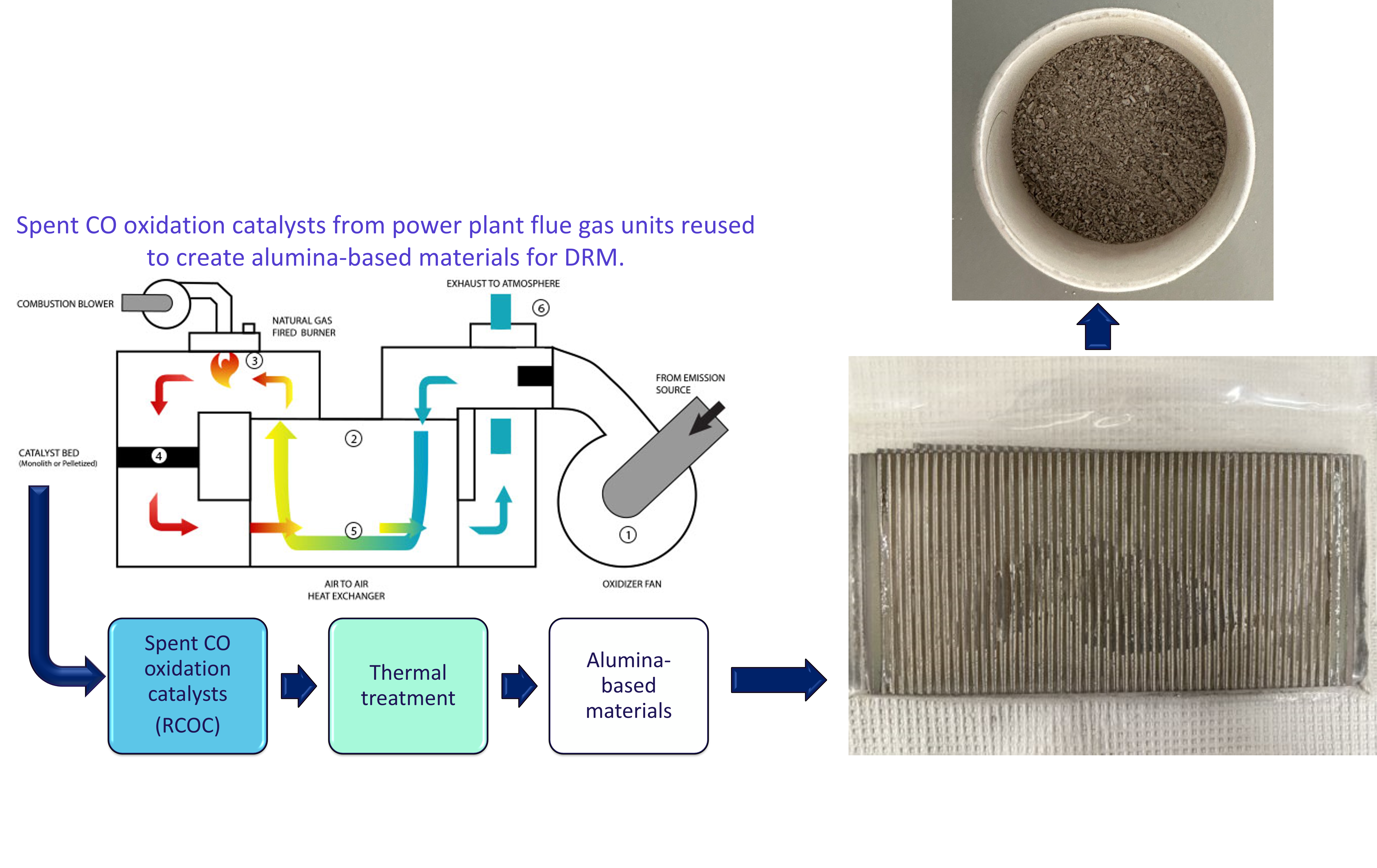

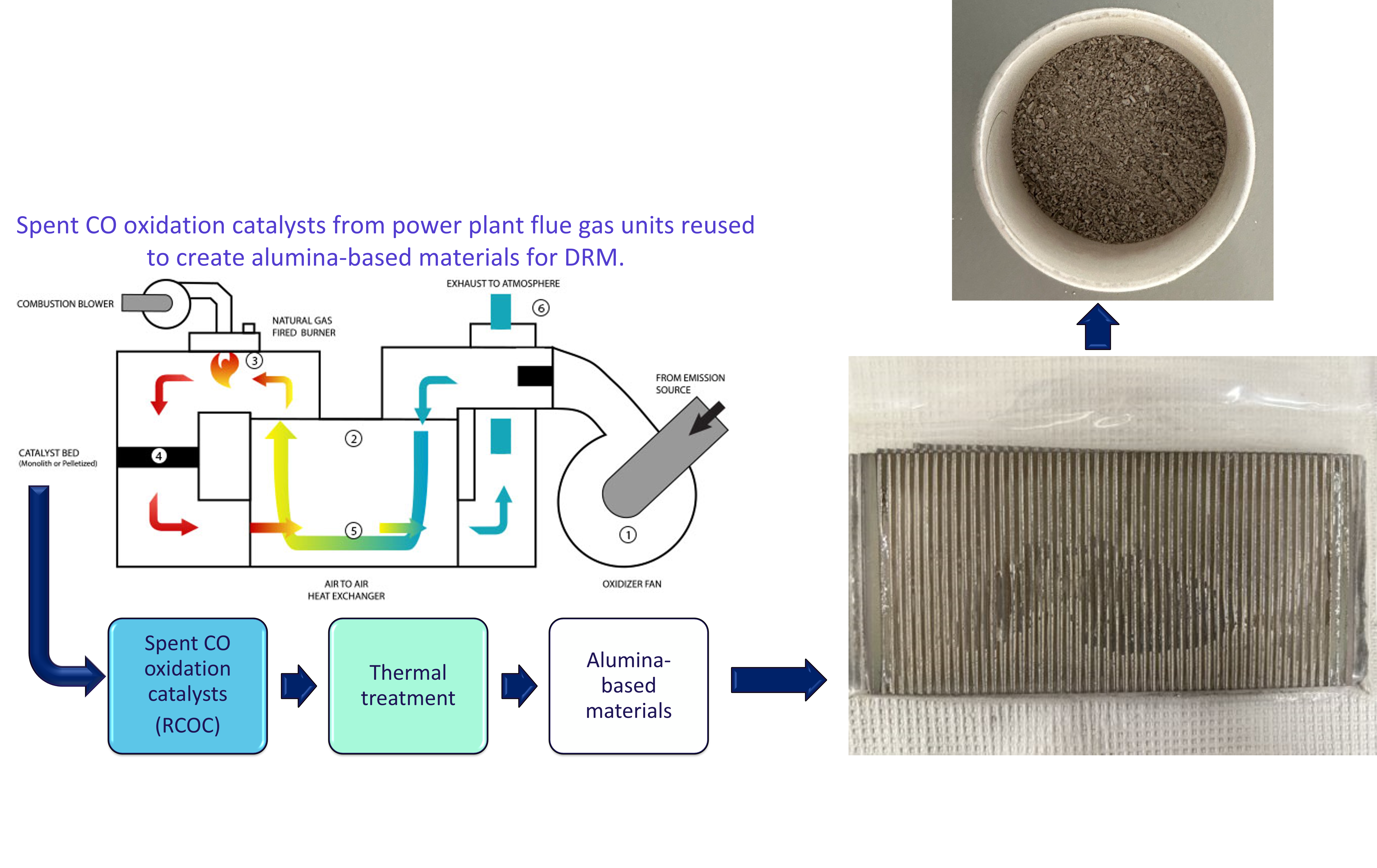

Spent catalysts represent a significant source of metal-containing waste, posing both environmental and economic challenges in their disposal. Repurposing these spent catalysts offers a sustainable solution by reducing waste and recovering valuable metals, which can be reused in other industrial catalytic applications. This study explores the reuse of spent CO oxidation catalyst from power plant flue gas units to develop alumina-based materials for the dry reforming of methane (DRM). The spent catalyst was thermally treated and doped with nickel via a wet impregnation method, resulting in a regenerated catalyst. A range of characterization techniques was employed, including XRD, BET surface area, SEM, TEM, H2-TPR, CO2-TPD, NH3-TPD, H2-pulse chemisorption, FT-IR, XPS, and TGA. The analysis of the pristine catalyst revealed a ductile Fe-Al-Cr alloy support with a ceramic catalytic layer of Al₂O₃ and La₂O₃, characterized by finely dispersed platinum particles. Platinum concentration in the catalytic layer reached approximately 4500 mg/kg, with uneven distribution and deposits of brown and white materials containing aluminum, lanthanum, oxygen, carbon, and platinum. The catalytic activity of the pristine material, as well as its nickel doped counterpart, was tested in a fixed-bed reactor for DRM, with 200 mg of catalyst reduced using 5% H2/Ar at 800°C and cooled to 750°C before introducing an equimolar CH4/CO2 gas mixture. Catalytic efficiency was monitored for 7 hours using an online mass spectrometer. Nickel doping improved methane conversion from 30% to 80% and carbon dioxide conversion from 35% to 95%, while maintaining an H2/CO ratio of 1, compared to 0.7 for the pristine catalyst without Ni doping. The doped catalyst demonstrated stability over the 7-hour test, underscoring the potential of spent catalysts for reuse in various industrial applications. This potential was further validated by a detailed techno-economic analysis for long-term implementation.