2025 AIChE Annual Meeting

(261f) Monitoring and Control of Semi-Continuous Separation Systems: A Toolkit from White to Black Box Approaches

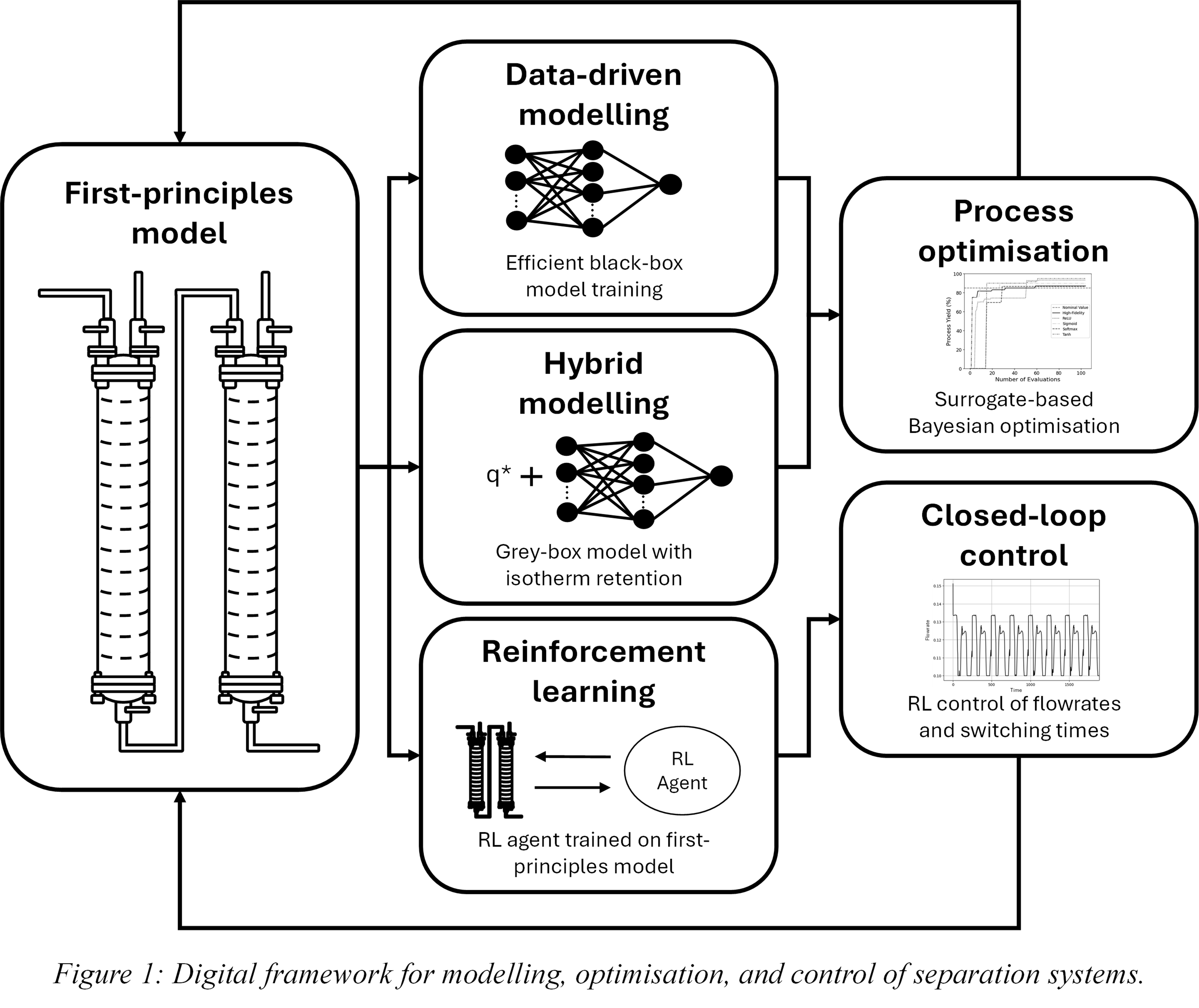

To address these challenges, in this work, we develop and propose a suite of digital tools (Figure 1) designed to support different stages of process development, from design and optimisation to real-time control. We focus on the case study of semi-continuous chromatography used for the purification of monoclonal antibodies (mAbs), a system characterised by stringent purity constraints, limited online sensing, and dynamic operation (Aumann & Morbidelli, 2007). The proposed framework integrates data-driven (black-box) models, hybrid (grey-box) models, and reinforcement learning (RL) control, each developed and purposed to align with distinct operating constraints.

Building on previously published modelling architectures, we develop and deploy a suite of data-driven and hybrid models of the separation process. The former uses Artificial Neural Networks (ANNs) trained on simulated cycles from a validated first-principles model, mapping pseudo-dynamic, measurable inputs to time-resolved elution profiles (Michalopoulou & Papathanasiou, 2024). The hybrid formulation embeds domain knowledge by retaining the separation isotherm to describe the underlying separation mechanism, while an ANN approximates the system’s dynamic response (Michalopoulou & Papathanasiou, 2025). The two modelling structures differ in their training requirements, predictive capabilities, and computational overhead, making them suitable for different deployment strategies.

The developed models are embedded within a Bayesian Optimisation (BO) framework to evaluate their effectiveness for time-constrained process optimisation. All optimisation results are benchmarked against the validated first-principles model, which serves as the ground truth for process behaviour. BO is used to iteratively explore the operating space, maximising yield while enforcing predefined purity thresholds. In scenarios where computational time is unconstrained, such as offline process design, the first-principles model achieves the highest process yield. However, when online optimisation is required within a single cycle time for cycle-to-cycle decision-making, the hybrid model offers a superior trade-off between accuracy and tractability. For real-time decision-making within seconds, only the black-box surrogate achieves sufficiently rapid exploration to generate viable control actions.

The digital framework is extended to closed-loop control using RL. A Proximal Policy Optimisation (PPO) agent is trained directly on the first-principles model from process start-up, learning adaptive policies to adjust flowrates and switching times in real-time. The agent optimises a multi-objective reward function incorporating yield, purity, and process duration, and demonstrates strong generalisation under disturbances in feed composition.

This work introduces a versatile and scalable digital framework for monitoring, optimisation, and control of semi-continuous separation systems. The framework employs data-driven modelling, suitable for rapid online decisions, isotherm-informed hybrid models, which support cycle-to-cycle optimisation with physical consistency, and RL for adaptive closed-loop control, each tailored to a distinct optimisation or control task. Together, these tools address fundamental limitations surrounding model scalability, generalisation, and autonomous operation across complex separation processes.

Acknowledgements

Funding from the UK Engineering & Physical Sciences Research Council (EPSRC) for the i-PREDICT: Integrated adaPtive pRocEss DesIgn and ConTrol (Grant reference: EP/W035006/1) and the IAA: Impact Acceleration Account (Grant reference: EP/X52556X/1) is gratefully acknowledged. The authors gratefully acknowledge the support of Dr. Emmanouil Papadakis (Novo Nordisk A/S) for his valuable input and industry expertise.

References

Armstrong, A., Horry, K., Cui, T., Hulley, M., Turner, R., Farid, S.S., Goldrick, S. & Bracewell, D.G. (2021) Advanced control strategies for bioprocess chromatography: Challenges and opportunities for intensified processes and next generation products. Journal of Chromatography A. 1639, 461914.

Aumann, L. & Morbidelli, M. (2007) A continuous multicolumn countercurrent solvent gradient purification (MCSGP) process. Biotechnology and Bioengineering. 98 (5), 1043–1055.

Baldea, M., Georgiou, A.T., Gopaluni, B., Mercangöz, M., Pantelides, C.C., Sheth, K., Zavala, V.M. & Georgakis, C. (2025) From automated to autonomous process operations. Computers & Chemical Engineering. 196, 109064.

Engell, S. & Toumi, A. (2004) Optimization and control of chromatography. Computer Aided Chemical Engineering. 18 (C), 9–22.

Kawajiri, Y. (2021) Model-based optimization strategies for chromatographic processes: a review. Adsorption. 27 (1), 1–26.

Kawajiri, Y. & Biegler, L.T. (2006) Large scale nonlinear optimization for asymmetric operation and design of Simulated Moving Beds. Journal of Chromatography A. 1133 (1–2), 226–240.

Kumar, V., Leweke, S., Heymann, W., von Lieres, E., Schlegel, F., Westerberg, K. & Lenhoff, A.M. (2021) Robust mechanistic modeling of protein ion-exchange chromatography. Journal of Chromatography A. 1660, 462669.

Michalopoulou, F. & Papathanasiou, M.M. (2025) An approach to hybrid modelling in chromatographic separation processes. Digital Chemical Engineering. 14, 100215.

Michalopoulou, F. & Papathanasiou, M.M. (2024) Assessment of data-driven modeling approaches for chromatographic separation processes. AIChE Journal. e18600.

Papathanasiou, M.M., Avraamidou, S., Oberdieck, R., Mantalaris, A., Steinebach, F., Morbidelli, M., Mueller-Spaeth, T. & Pistikopoulos, E.N. (2016) Advanced control strategies for the multicolumn countercurrent solvent gradient purification process. AIChE Journal. 62 (7), 2341–2357.

Rüdt, M., Brestrich, N., Rolinger, L. & Hubbuch, J. (2017) Real-time monitoring and control of the load phase of a protein A capture step. Biotechnology and Bioengineering. 114 (2), 368–373.

Ündey, C., Ertun, S., Mistretta, T. & Looze, B. (2010) Applied advanced process analytics in biopharmaceutical manufacturing: Challenges and prospects in real-time monitoring and control. Journal of Process Control. 20 (9), 1009–1018.