2025 AIChE Annual Meeting

(318f) Modulating Specific Ion Effects in Dilute Salt Hydrates for Dilute Acid Cellulose Hydrolysis

While there are various approaches to pretreatment, the authors hypothesize that the dilute acid hydrolysis of mechanically treated cellulose in incorporation with different metal salt hydrates (such as LiCl, KCl, NH4Cl, GdmCl) can be used to enhance glucose yield by altering the physical structure of cellulose and reducing electrostatic repulsion between the cellulose surface and the diluted hydrochloric acid (HCl) used for hydrolysis.

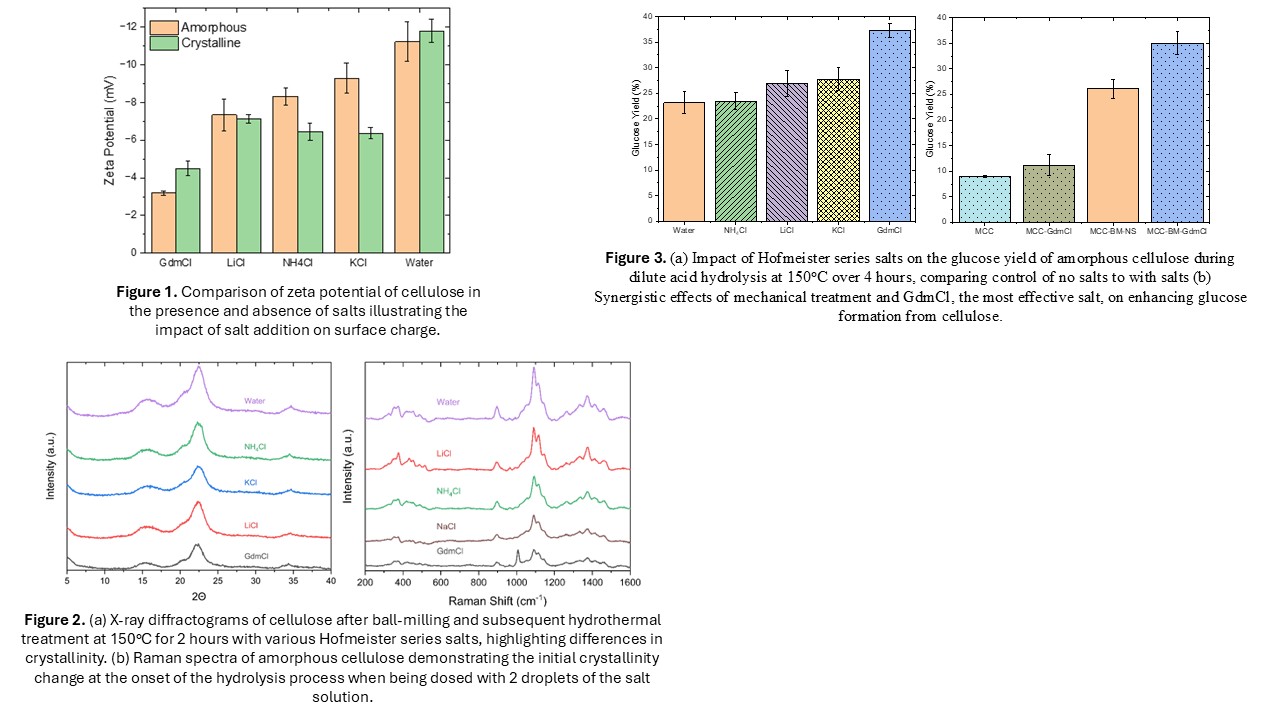

X-ray diffraction, Raman spectroscopy and zeta potential analysis were used to evaluate the effects of the different cations. As shown in Figure 1, metal salt hydrates alter the surface zeta potential of cellulose towards neutrality, decreasing repulsion with HCl. Figures 2a and 2b, illustrate that these salts also suppress recrystallation in aqueous environments before and after hydrolysis. Figure 3 is a culmination of these different effects at play, demonstrating how the combined effects of mechanical amorphization and salt addition, result in a significant enhancement in glucose yield.

In summary, pretreating cellulose with metal salt hydrates – especially GdmCl – has proven to be an effective strategy for enhancing glucose yields from hydrolysis. Our results demonstrate that GdmCl reduces the negative surface charge of cellulose, suppresses its recrystallization in aqueous environments (such the case for hydrolysis), and improve glucose yields compared to control samples without added salts and mechanical treatment. These findings suggest a promising, low-cost route for improving biomass conversion through green and scalable process enhancements.