2025 AIChE Annual Meeting

(439c) Modeling Electrode Compaction in Battery Manufacturing: Insights into Microstructural Behavior and Process Optimization

Authors

Two distinctive DEM modeling approaches have been tested and compared. First, the bonded sphere model is used, where active material particles and binder are represented as discrete bodies interconnected by elastoplastic bonds. Each bond undergoes elastic and plastic deformation, enabling computation of energy dissipation during roller compaction and tracking of bond breakage events. This bond-level energy dissipation is critical for predicting concentrations of local stress and understanding how binder mechanics influence thickness reduction and porosity evolution. Second, a deformable-solid DEM approach is implemented to explicitly model plastic deformation within the solid particles themselves, enabling the simulation of realistic particle flattening, contact surface enlargement, and fracture behavior during compression. This hybrid finite-element approach [1] is adapted for GPU acceleration to make calendaring simulations computationally feasible.

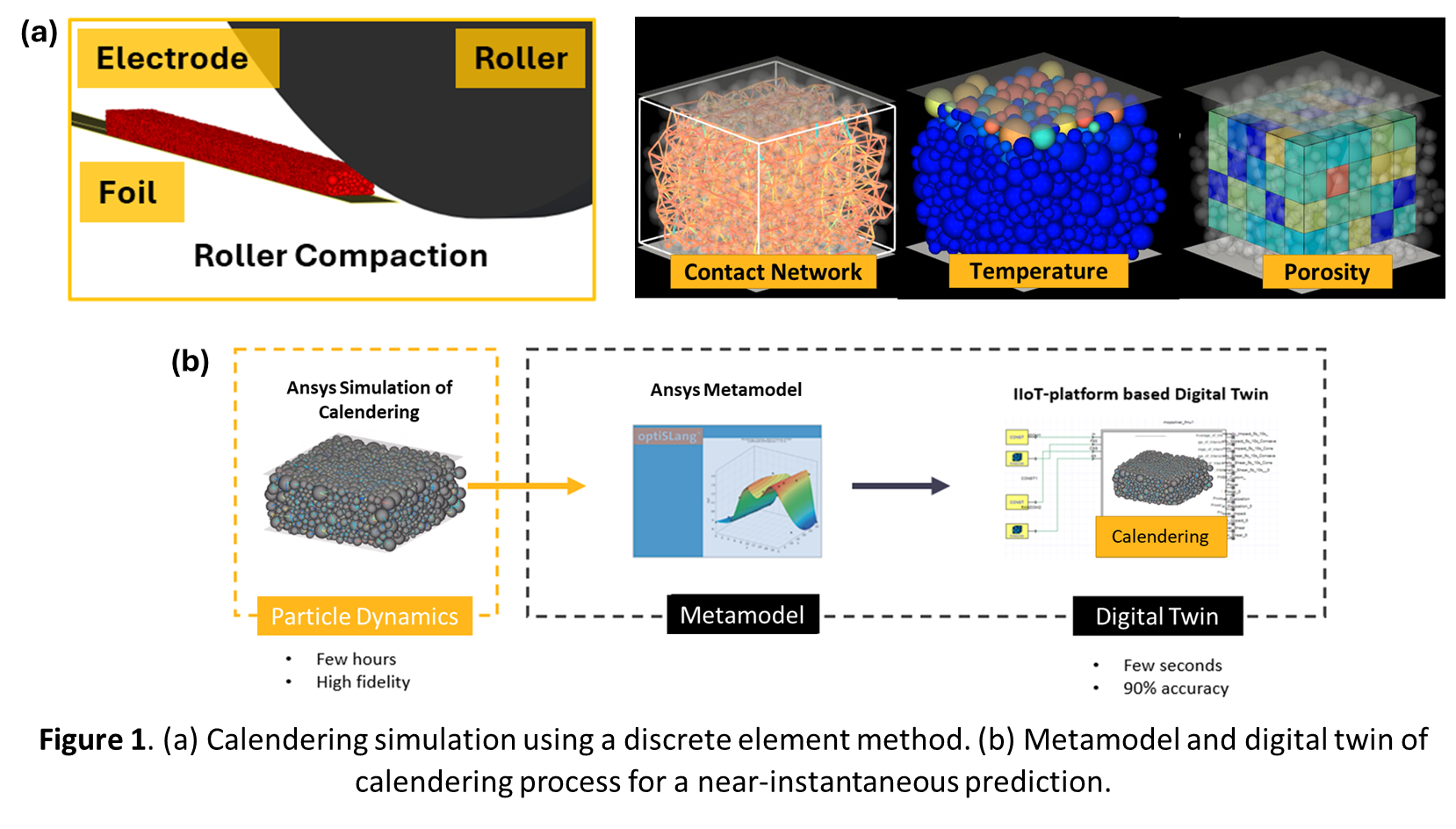

The simulation domain represents a section of the electrode being compressed by a pair of compacting rollers (Figure 1-a). Particle assemblies with experimentally derived size distributions and binder ratios are generated with realistic packing structures [2]. The models are run under varying process parameters: initial electrode thickness, roll gap distance, and roller speed. Both bond model and deformable-solid simulations are used to evaluate key output metrics, including thickness reduction, porosity and tortuosity evolution, stress distribution, and mechanical anisotropy.

Preliminary results show that while both models capture the general trends of thickness and porosity reduction, the bond model shows localized binder breakage and more abrupt stress relief, whereas the deformable-solid model captures gradual redistribution of stress through plastic flow and shows higher fracture rates in oversized particles. The deformable-solid model distributes energy throughout the particle body and enables a more continuous compaction process [3]. Altogether, the bond model offers faster runtimes, while the deformable‑solid method provides deeper insight into particle plasticity and fracture.

To accelerate industrial optimization, we build a reduced-order model (ROM) from this simulation framework. This ROM map process parameters to output metrics (e.g., final thickness, porosity), enabling near‑instantaneous what-if scenario evaluations. We then deploy the ROMs within a digital‑twin platform, integrating real‑time thickness sensor data to drive a physics-aware control system. This digital‑twin deployment offers battery manufacturers powerful tools to optimize calendaring processes, enhance electrode uniformity, and improve production. As DEM solvers and GPU hardware continue to advance, such integrated simulation‑driven methodologies will become indispensable for next generation batteries.

References:

[1] Potapov, Alexander V., and Charles S. Campbell. "A Hybrid Finite-Element Simulation of Solid Fracture." International Journal of Modern Physics C, vol. 7, no. 2, 1996, pp. 155–180.

[2] Giménez, Clara Sangrós, Benedikt Finke, Christine Nowak, Carsten Schilde, and Arno Kwade. "Structural and Mechanical Characterization of Lithium-Ion Battery Electrodes via DEM Simulations." Advanced Powder Technology, vol. 29, no. 10, 2018, pp. 2312–2321.

[3] Schreiner, Daniel, Andreas Klinger, and Gerhard Reinhart. "Insights into Influencing Electrode Calendaring on the Battery Performance." Advanced Energy Materials, vol. 13, no. 15, 2023, p. 2300973.