2025 AIChE Annual Meeting

(377d) Model-Driven Optimization and Control Studies for Flushing Dynamics in Multi-Product Pipeline Systems

Authors

The objective is to develop a computational model to inform and develop an optimized flushing strategy that enhances efficiency, minimizes product loss, and ensures product integrity by incorporating real-time measurement devices, such as an inline viscometer [4] and a data-acquisition system [5].

Two distinct flushing methodologies were examined: (i) (i) direct oil-to-oil flushing, in which a plug of fresh oil is introduced to displace the residual oil, and (ii) air-blowing followed by flushing, where compressed air is initially introduced to remove most of the residual oil before introducing the fresh oil. Viscosity was used as a primary performance metric, continuously monitored through an inline viscometer and a real-time data acquisition system. This real-time monitoring enabled the precise tracking of transitional viscosity profiles and also identifying the optimal flush duration and stopping time.

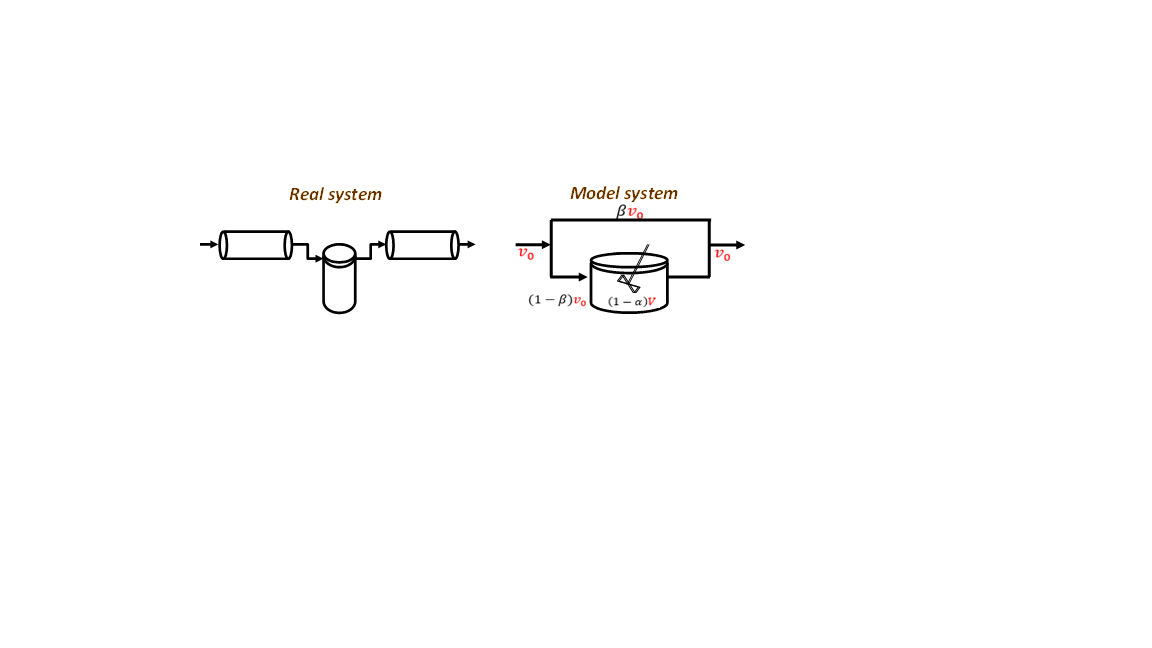

Mole balance models for pipeline flows were developed with two assumptions: (i) well-mixed, and (ii) two-compartment systems. The well-mixed model when validated with experimental observations revealed deviations ranging from 15 to 40%. However, when we tested the two-compartment model which divided the pipeline into two geometric components: a tubular section (i.e. plug flow) and a tank (i.e. well mixed) section and accounting for deviations from well-mixed systems, showed a significant rise in accuracy (less than 2% deviation). This two-compartment model introduced correction parameters: alpha (α), which accounts for flow variations and their influence on mixing, and beta (β), which quantifies the portion of residual oil that remains within the pipeline without being displaced by the flushing fluid. The incorporation of these parameters enhances the predictive accuracy of the model, allowing us to apply it for further analysis and control of flushing dynamics.

Current industrial flushing practices are predominantly reliant on operator experience. With the comprehensive flushing model, our objective is to computationally determine the optimal flushing conditions for various oil changeovers, minimizing product loss and improving efficiency. Through optimal control, we aim to predict the precise flush time required to achieve the desired purity, eliminating reliance on trial-and-error methods. By integrating systematic experimentation with mathematical modeling, this study advances the understanding of flushing dynamics and provides a framework for real-time optimization and control.

References

[1] B. Gao et al., “Improved Design of Flushing Process for Multi-Product Pipelines,” presented at the Foundations of Computer-Aided Process Design, Breckenridge, Colorado, USA, Jul. 2024, pp. 137–144. doi: 10.69997/sct.171679.

[2] S. Gao and C. Dennar, “Computational Simulation of Multi-Product Flow in an Oil Transportation Pipeline,” Appl. Mech. Mater., vol. 590, pp. 161–165, 2014, doi: 10.4028/www.scientific.net/AMM.590.161.

[3] S. S. Jerpoth, R. Hesketh, C. S. Slater, M. J. Savelski, and K. M. Yenkie, “Strategic Optimization of the Flushing Operations in Lubricant Manufacturing and Packaging Facilities,” ACS Omega, vol. 8, no. 41, pp. 38288–38300, Oct. 2023, doi: 10.1021/acsomega.3c04668.

[4] “Hydramotion Resonant Technology | Viscosity Measurement.” Accessed: Sep. 19, 2023. [Online]. Available: https://hydramotion.com/en/technical

[5] “cRIO-9045 Specifications - NI.” Accessed: Feb. 07, 2024. [Online]. Available: https://www.ni.com/docs/en-US/bundle/crio-9045-specs/page/specs.html