2025 AIChE Annual Meeting

(595d) Model-Based Optimization of Fermentation Strategy for Cost-Effective Production of O-Acetyl-L-Homoserine

Authors

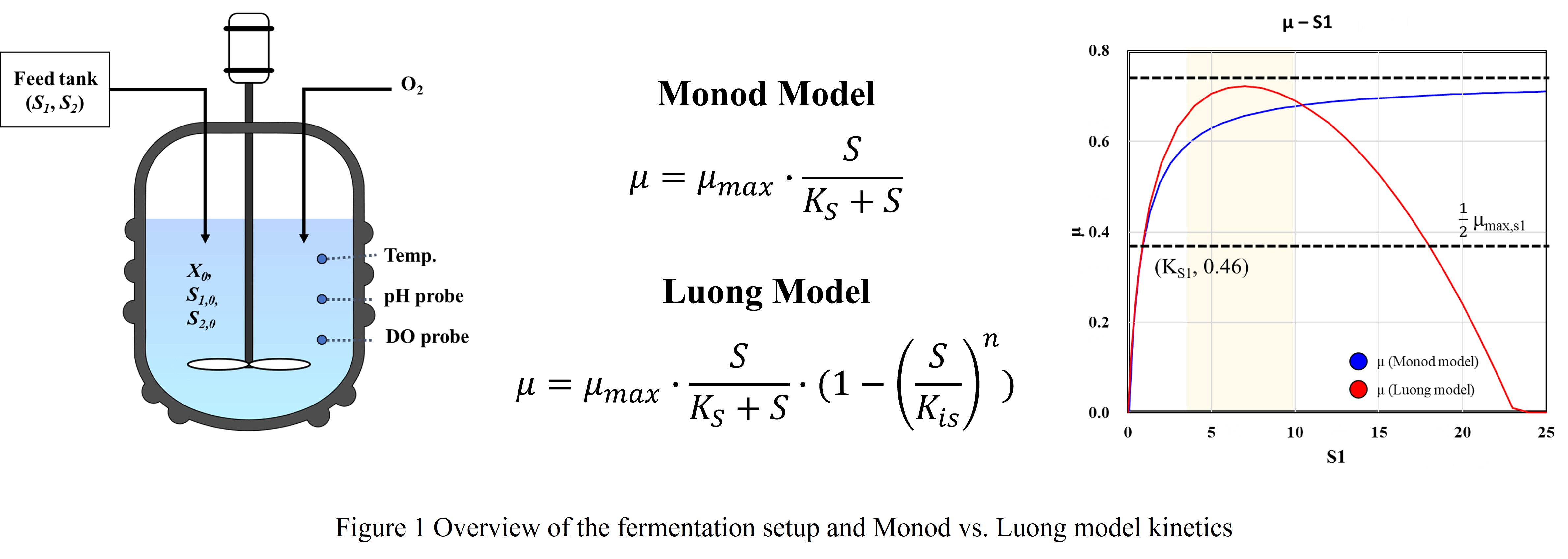

In this study, we develop a mathematical model of aerobic fed-batch fermentation for OAH production using Corynebacterium to derive an optimal feeding strategy. The process begins with a batch phase in a 30 L bioreactor, followed by a fed-batch phase using a single-feed system delivering sucrose and acetic acid. We first tested various feed concentration profiles experimentally. Based on the experimental data, we construct a kinetic model to predict the dynamic behavior of the fermentation. Key parameters are initially estimated using the Monod model [03], followed by a modified Luong-type model [04] to account for substrate inhibition under excess substrate concentrations. Simulation results indicate that maintaining substrate concentrations between the saturation constant (Ks) and inhibition constant (Kis) enhances productivity and thus lowers production costs. Optimization of the feeding rate and concentration profile during the fed-batch phase is then carried out to further minimize the cost of OAH production. This study presents a systematic framework that combines sequential kinetic modeling and process optimization, offering practical insights for the economically viable and scalable production of OAH in industrial fermentation.

Reference

1. Flevaris, K., & Chatzidoukas, C. (2021). Optimal fed-batch bioreactor operating strategies for the microbial production of lignocellulosic bioethanol and exploration of their economic implications: A step forward towards sustainability and commercialization. Journal of Cleaner Production, 295, 126384

2. Shah, P., Sheriff, M. Z., Bangi, M. S. F., Kravaris, C., Kwon, J. S., Botre, C., & Hirota, J. (2022). Multi‐rate observer design and optimal control to maximize productivity of an industry‐scale fermentation process. AIChE Journal, 69(2).

3. Monod, J. (1949). The growth of bacterial cultures. Annual Review of Microbiology, 3(1), 371–394.

4. Luong, J. H. T. (1987). Generalization of monod kinetics for analysis of growth data with substrate inhibition. Biotechnology and Bioengineering, 29(2), 242–248.