2025 AIChE Annual Meeting

(390d) Model-Based Evaluation of the Economic Impact of Ammonium Bisulfate Formation on Low-Grade Waste Heat Recovery Via Organic Rankine Cycle

Authors

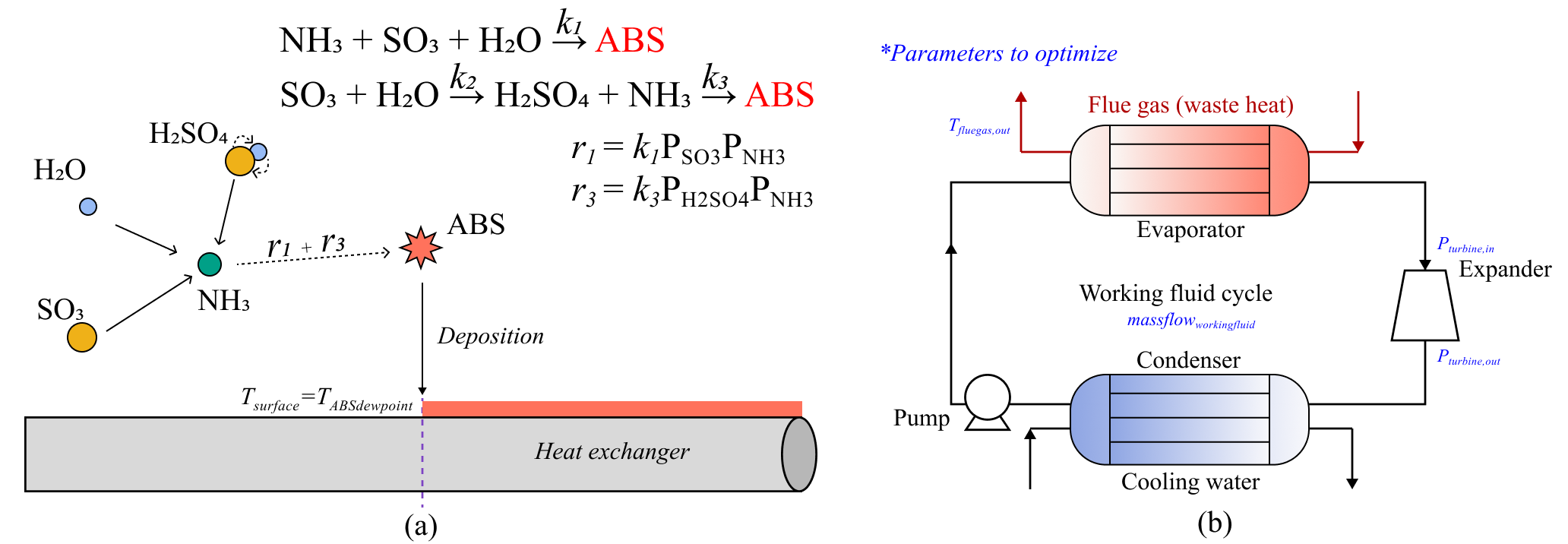

In this work, we analyze the economic impact of ABS formation in heat exchangers used for waste heat recovery via ORCs. Pseudo-reaction kinetic models for ABS and sulfuric acid formation are developed to describe deposition behavior on heat exchanger surfaces (Fig. 1a). These kinetic models are integrated into a mathematical model of an ORC with discrete-time variables, which is then utilized to optimize its operating conditions (e.g., working fluid pressure, flowrate), considering ABS formation and heat transfer degradation during running time (Fig. 1b).

Our results show that the net profit can be reduced by 12.0 to 38.6% after 1 year of operation, depending on the assumed kinetic parameters of ABS formation. This corresponds to a 4.1 to 22.3% reduction in cumulative annual benefit. By estimating the extent of ABS formation and its economic implications for heat exchanger networks and energy recovery systems, this study highlights the challenges associated with low-temperature waste heat recovery. These findings will provide insights to guide future improvements in the design and operation of ORCs.

Reference

1. Forman, C., Muritala, I. K., Pardemann, R., & Meyer, B. (2016). Estimating the global waste heat potential. Renewable and Sustainable Energy Reviews, 57, 1568-1579.

2. IRENA (2020), “Net-zero iron and steel production: challenges, options and what needs to happen now”

3. Ben-Mansour, R., El-Ferik, S., Al-Naser, M., Qureshi, B. A., Eltoum, M. A. M., Abuelyamen, A., ... & Ben Mansour, R. (2023). Experimental/Numerical Investigation and Prediction of Fouling in Multiphase Flow Heat Exchangers: A Review. Energies, 16(6), 2812.

4. Qing, M., Lei, S., Kong, F., Liu, L., Zhang, W., Wang, L., ... & Xiang, J. (2022). Analysis of ammonium bisulfate/sulfate generation and deposition characteristics as the by-product of SCR in coal-fired flue gas. Fuel, 313, 122790.

Figure 1. Schematic diagram of (a) ABS formation kinetic modeling (b) Organic Rankine cycle optimization