2025 AIChE Annual Meeting

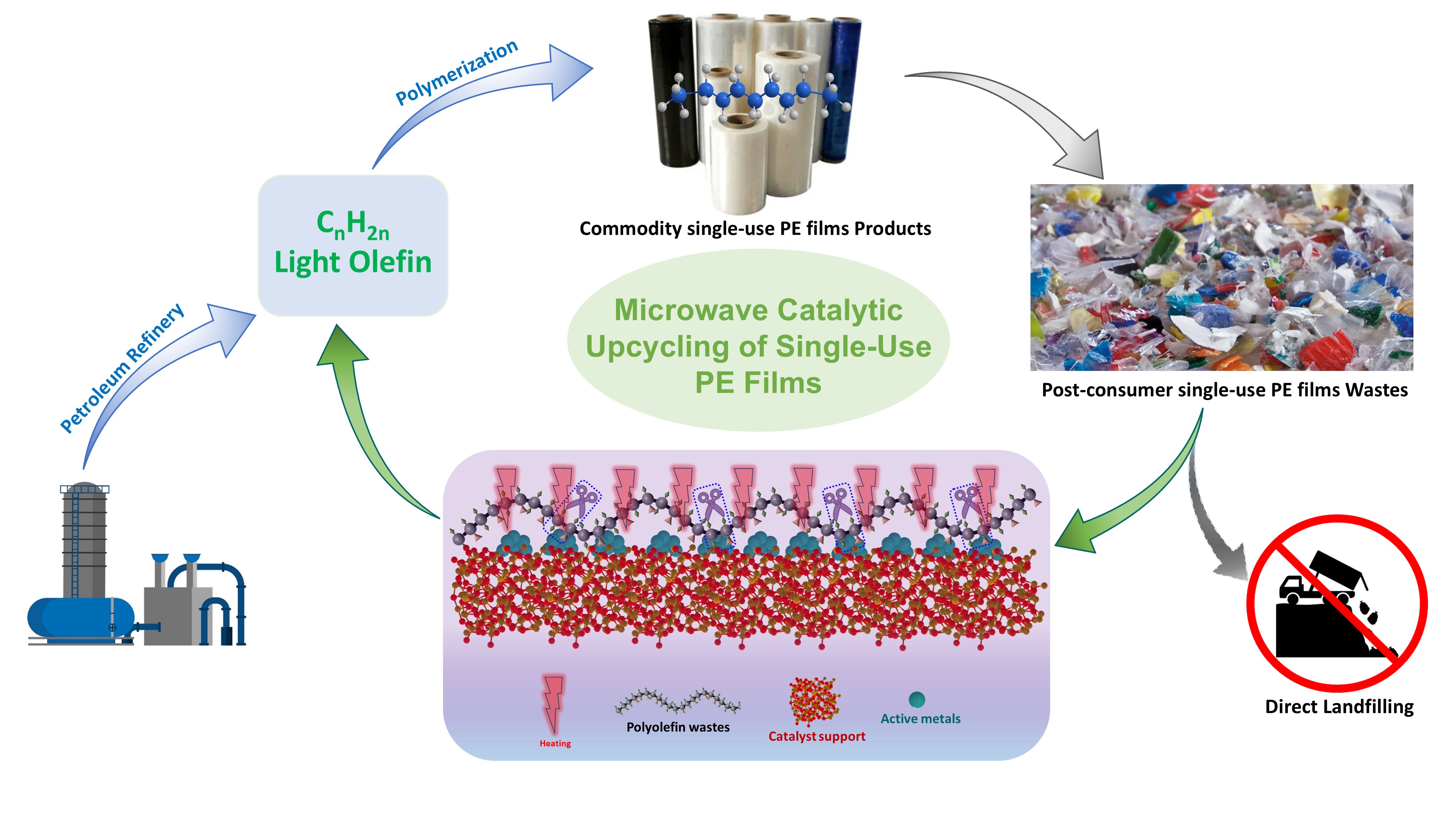

(704b) Microwave-Catalyzed Selective Upcycling of Single-Use Polyethylene Films to Light Olefin

Authors

Using a Fe-based catalyst, complete conversion of PE films (100%) and a light olefin yield over 70 wt.% were achieved at 400 °C and ambient pressure under microwave irradiation. In contrast, conventional thermal treatment of PE films under identical conditions resulted in no conversion, and even at 600 °C, the light olefins yield was limited to 64 wt.% despite full PE conversion.

The catalytic system exhibited excellent stability and recyclability under microwave conditions. Density functional theory (DFT) calculations further elucidated the crucial role of microwave-specific effects and catalyst-microwave interactions in promoting selective depolymerization of PE film waste. This work offers a scalable and sustainable solution for transforming single-use PE films into valuable chemical feedstocks, addressing a critical challenge in plastic waste management.