2025 AIChE Annual Meeting

Microfluidic Production of PLGA Nanoparticles for Drug Delivery Applications

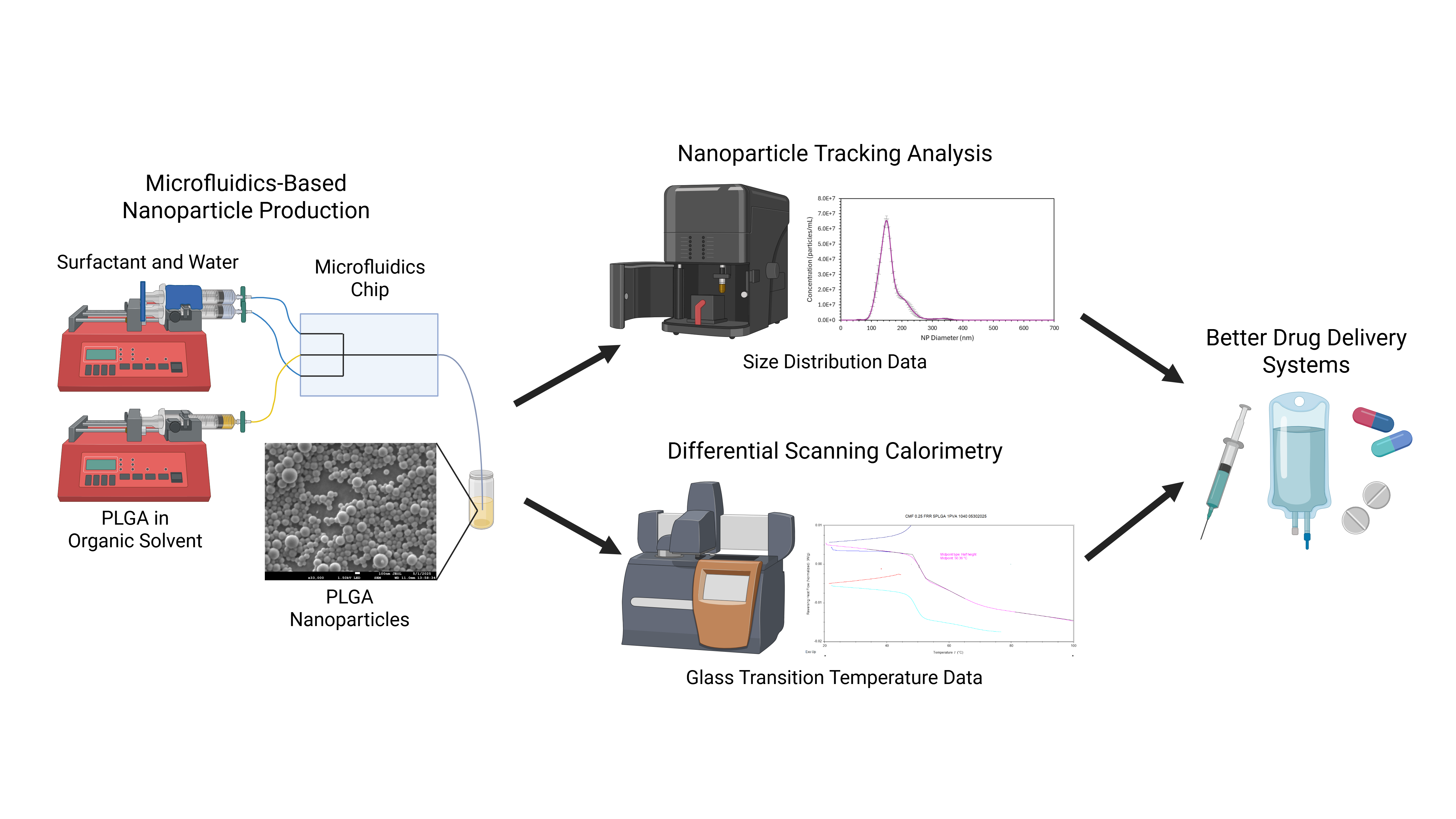

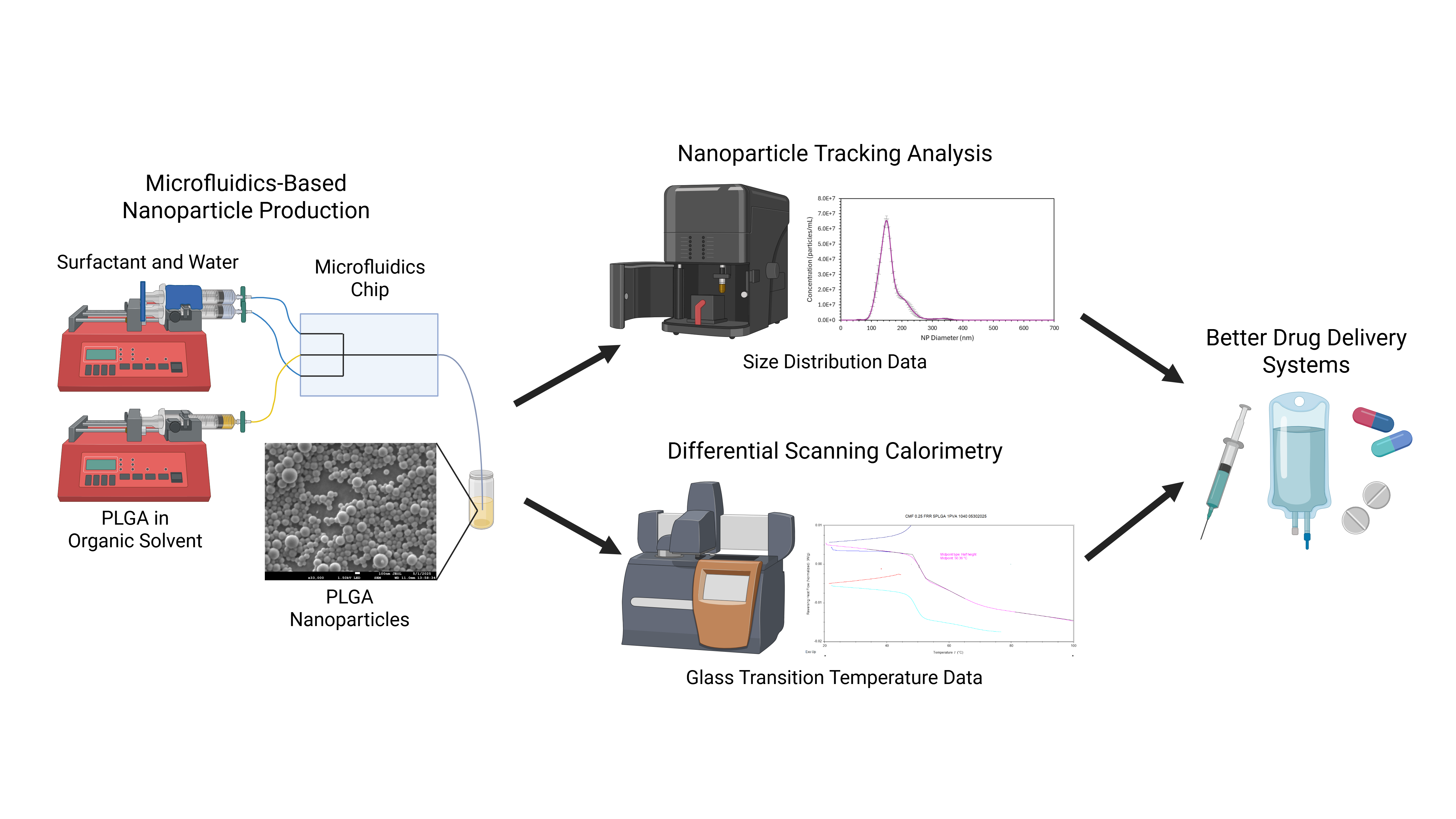

Conventional cancer treatments (ex. chemotherapy) are very limited because they harm both tumors and healthy cells. Meanwhile, a targeted drug delivery system would safely transport drugs through the bloodstream to act only on cancer cells while leaving the rest of the body unharmed. This system would improve patients' physical health, mental health, and quality of life. Poly(lactic-co-glycolic) acid (PLGA) nanoparticles are of especial interest as drug vehicles because they are long-lasting in the body, cross biological barriers, and break down into biocompatible lactic acid and glycolic acid molecules. However, a significant issue with PLGA vehicles is burst release, where a large amount of drug rapidly leaves the vehicle instead of releasing slowly and consistently at its intended destination. Burst release is related to the glass transition temperature (Tg) of the PLGA vehicles. Tg is the temperature at which a molecule changes from a rigid, “glassy” state to a flexible, rubbery state. If the body heats the PLGA vehicle above its Tg, drug molecules rapidly escape, reducing the drug’s efficacy and increasing the risk of toxicity. As of now, the relationship between Tg and particle size in PLGA is under-researched. To determine how size affects Tg, we need to produce PLGA nanoparticles with samples of various diameters. Traditional nanoparticle production methods introduced issues. Nanoprecipitation produces particles of inconstant size in each sample. Nanoemulsion produces constant particle sizes, but requires surfactant to avoid particle aggregation. This process leaves irregular amounts of surfactant on the finished nanoparticles, dramatically affecting Tg measurements. To accurately determine the relationship between nanoparticle Tg and particle size, we need to create PLGA nanoparticles of similar size in each sample and constant residual surfactant concentrations. To solve this problem, we chose a microfluidics system, a novel approach for both controlled particle production and constant residual surfactant levels. We vary microfluidics parameters (ex. PLGA concentration, flow rates) to produce nanoparticle samples with a range of diameters. After processing particles, we collect data on size distribution using Nanoparticle Tracking Analysis (NTA). This presentation will present details of our microfluidics approach and resulting nanoparticle diameters. Understanding the relationship between Tg and nanoparticle size is crucial information for designing PLGA nanoparticles that control for burst release. This advancement would be a critical step in producing functional targeted drug delivery systems, with the potential to transform medicine, pharmacology, and cancer therapy.