2025 AIChE Annual Meeting

(565h) Metal Oxide Surface Engineered Polymeric Membranes with Superior Antifouling Properties for Efficient Separation of Crude Oil Emulsions

Authors

Bratin Sengupta - Presenter, Argonne National Laboratory

Noa Ram, Technion?Israel Institute of Technology

Yining Liu, Argonne National Laboratory

Tamar Segal-Peretz, Technion, Israeli Institute of Technology

Seth Darling, Argonne National Laboratory

Jeffrey W. Elam, Argonne National Laboratory

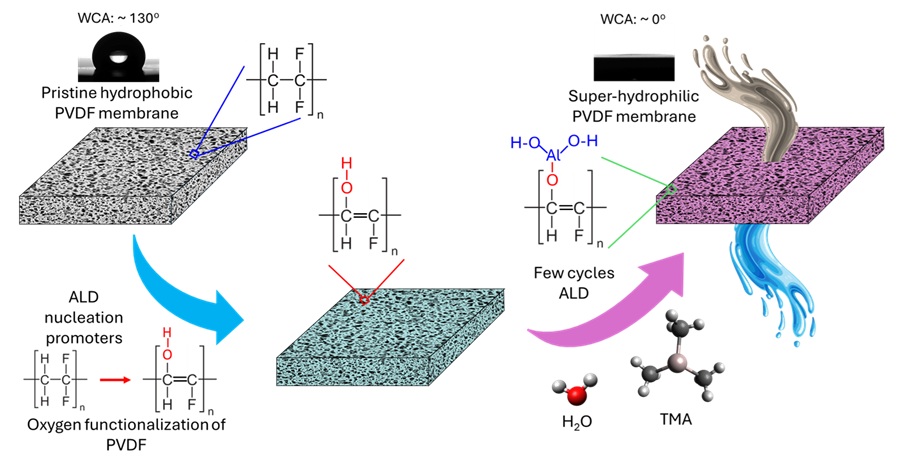

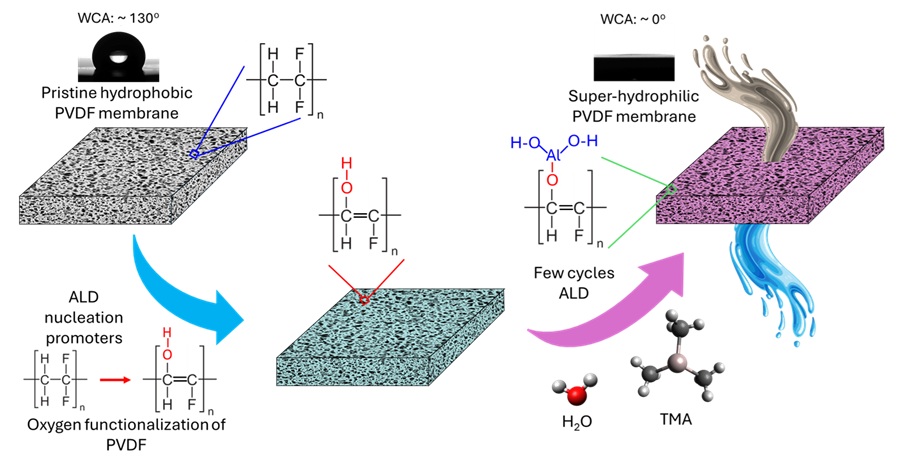

Fouling is a grand challenge which causes decline in the throughput of a membrane system, especially for applications pertaining to water treatment. Among various polymeric membranes, polyvinylidene fluoride (PVDF) is one of the most promising polymers for membrane fabrication, due to its inertness and stability. However, PVDF membranes suffer from intense fouling due to their inherent hydrophobicity. Post-synthetic surface functionalization of such membranes is an effective strategy to increase the membrane-foulant interaction energy and reduce fouling. In this regard, vapor phase surface functionalization is particularly promising since it allows formation of ultrathin metal oxide films (< 2 nm), which impart minimal change to the pore structure and morphology of pristine membranes. Thin layers of metal oxides impart hydrophilicity and are often positively charged at the pH of the wastewater, realizing high membrane – foulant interaction energy. Atomic Layer Deposition (ALD), a scalable, vapor phase self-limiting reaction technique can be used to deposit ultrathin layers of metal oxides on polymer membrane surfaces to impart anti-fouling properties. The ALD of metal oxides is exceedingly difficult on PVDF due to the inertness of its surface which necessitates large numbers of cycles of ALD to grow metal oxides. This reduces scalability, hindering roll-to-roll membrane production and oftentimes constricts the pores due to island growth inside the pores, reducing water permeance. We envision that a simple pre-treatment step would impart well dispersed ALD nucleation moieties for uniform metal oxide deposition during ALD. By incorporating such pre-treatment steps, we were able to impart similar anti-fouling properties using one ALD cycle which is equivalent to pristine PVDF membranes modified with >150 ALD cycles. Apart from > 99% flux recovery, with ~1% irreversible flux loss, our modified PVDF membrane shows ~ 50% increase in water permeance with ~50% increase in humic acid rejection. We achieved over 99% permeance recovery after oil-water emulsion separation and these membranes achieved over 98% crude oil separation from its stable emulsions for over 100 h continuous operation with pure water production of over 12,000 liter per sq. meter of membrane area, while operating under 1 bar transmembrane pressure. This work shows how a simple, facile pre-functionalization step prior to ALD can potentially make such post treatment modifications scalable for roll-to-roll production of super-hydrophilic membranes.