2025 AIChE Annual Meeting

(39h) Mechanochemical Regeneration of Sodium Borohydride (NaBH4) : Optimization, Characterization and Prediction.

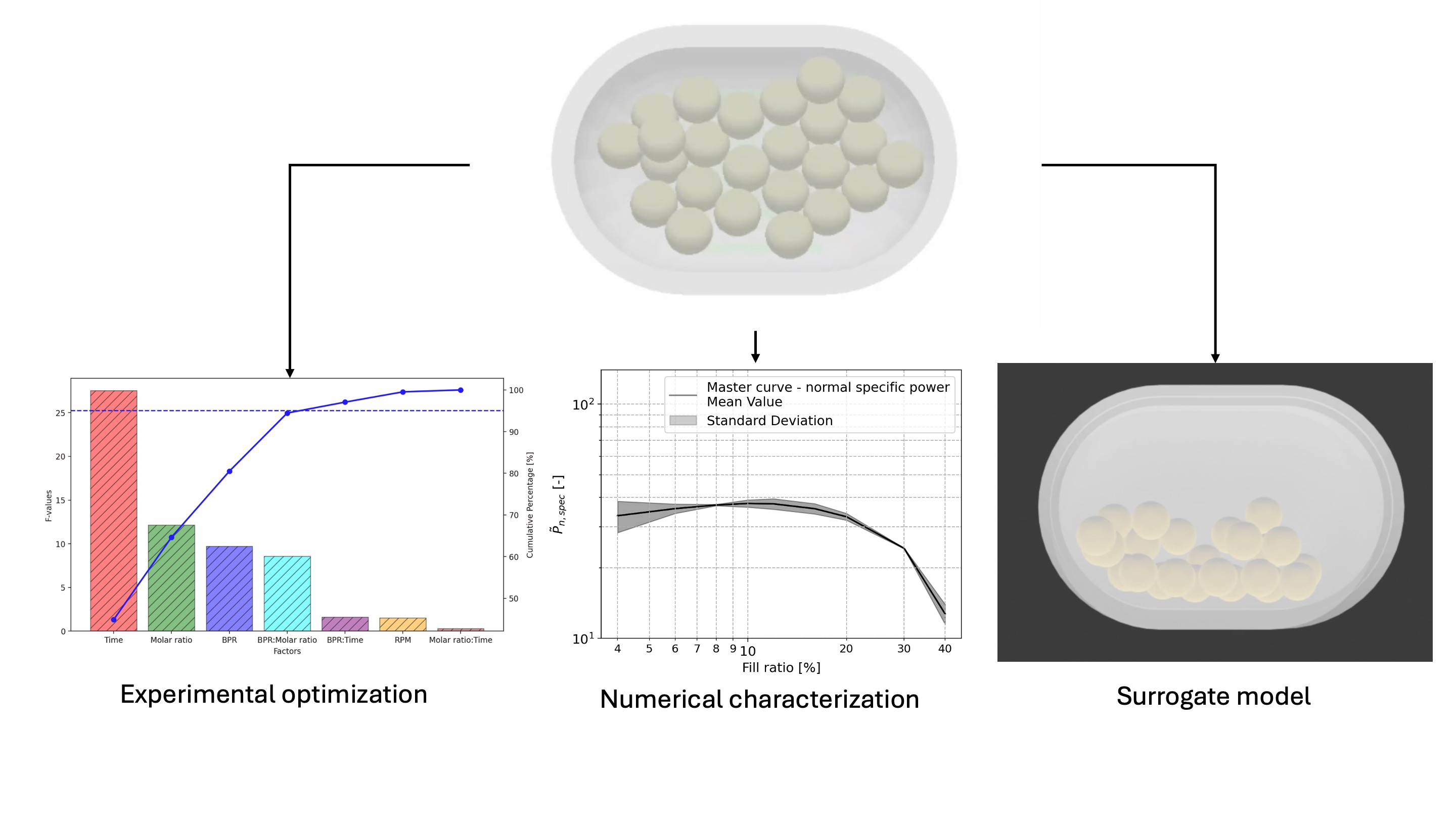

Experimentally, a systematic investigation of key operational parameters—milling time, ball-to-powder ratio, molar ratio, and rotational speed—reveals that prolonged milling and the careful balance between ball-to-powder and reactant ratios are crucial for achieving high conversion yields. In addition, discrete element method simulations are used to characterize the mechanics of ball milling by quantifying normal and tangential energy dissipation in a machine-independent manner, thereby allowing the results to be generalized beyond the specific equipment studied. Master curves developed from these simulations enable the prediction of energy transfer under untested operational conditions, highlighting the roles of fill ratio, ball size, and rotational speed in determining process efficiency.

Using machine learning techniques, we combine the energy dissipation profiles with experimental yield data, connecting the mechanics with the chemistry and enabling quick iterative testing for the full spectrum of operational variables. Finally, we explore the potential that generative (AI) surrogate models can have to facilitate system design and quantification.

Our integrated approach provides a robust framework for optimizing both the mechanochemical process and the design of milling equipment. This synergy between experimental insights and simulation-driven predictions paves the way for more efficient and scalable mechanochemical technologies.