2025 AIChE Annual Meeting

(451g) Mechanistic Insight and Improved Study of Direct Methane Upgrading Using Advanced Electromagnetic Catalysis Approach

Authors

The current shift to electrification of catalytic processes has seen the implementation of advanced electromagnetic (EM) reactors like- radiofrequency/Induction (RF) reactors as an efficient heating medium in select heterogenous catalytic processes. RF induction provides targeted heating, site-selective heat delivery and high heat management. In this study, the focus is to leverage the unique heating properties of RF on catalytic CH4 upgrading process and provide further understanding in the reaction network. Ultimately, the aim is to demonstrate a highly selective and scalable direct catalytic CH4 upgrading process using RF reactor.

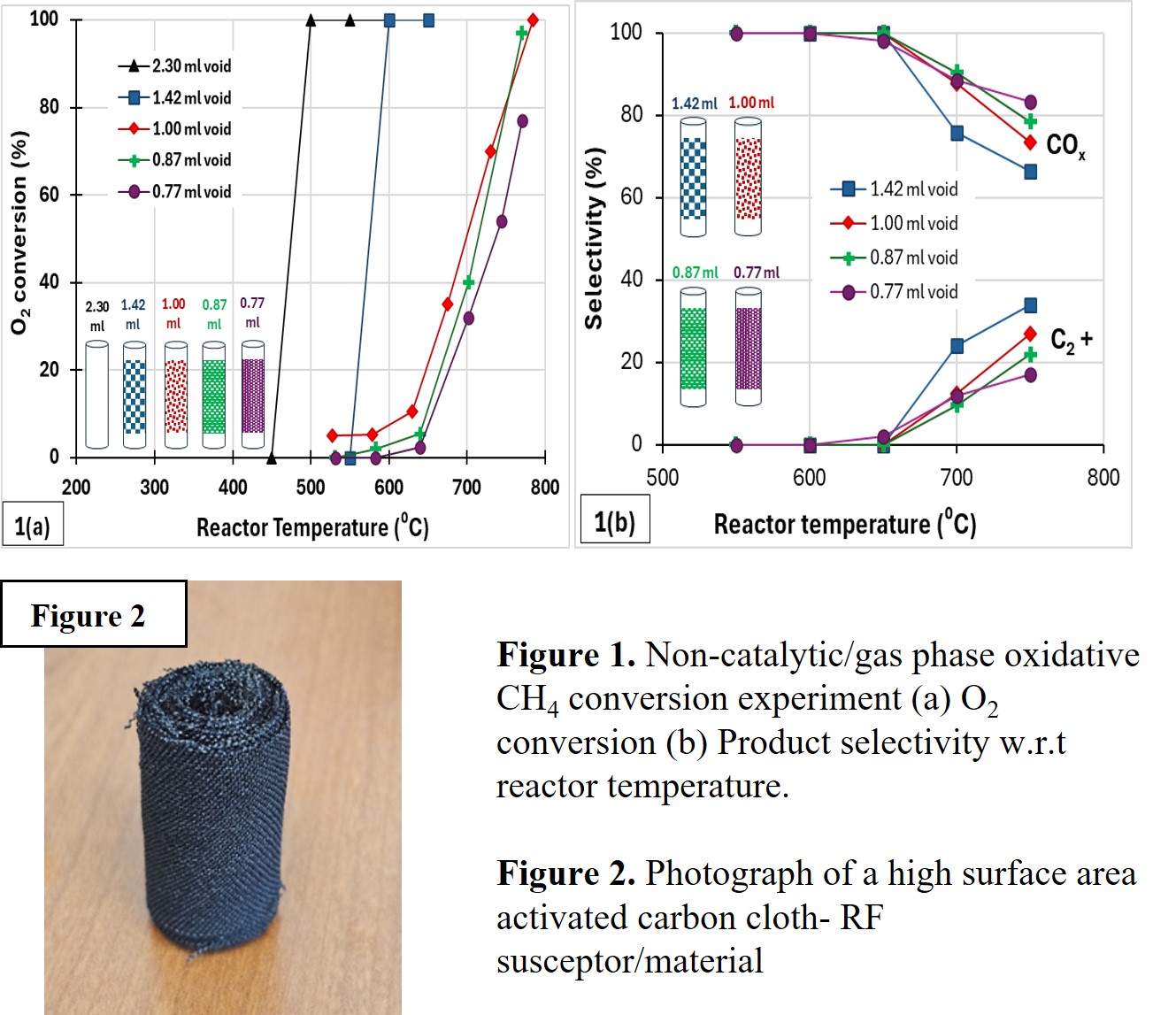

This study investigates the homogenous/gas-phase oxidative conversion of CH4 for both conventional (furnace heating) and RF reactors. Various RF reactor configurations as well as different RF susceptors/catalytic materials will be tested. The homogenous/gas-phase experiment was done using inert fixed-bed conventional reactors of different bed void volume. The observed activity, as shown in Figure 1(a), clearly depicts a linear dependency between gas phase activity and bed void volume. Since the reactors were filled with inert material, the activity observed, and products formed are considered predominantly homogenous/gas-phase propagated. This result provides insight into how gas phase CH4 conversion can be mechanistically controlled using bed void volume. Figure 1(b) also indicates that there are formations of both desired/coupling (C2+) and undesired/combustion products (COx); with majority being the combustion products.

This preliminary data encourages the need to employ RF heating due to its targeted heating that heats only the bed material/particles and not the gas phase eliminating or reducing excessive gas phase activity which leads to undesired products (combustion). Non-catalytic heating studies are carried out with the RF material/susceptor (figure 2- carbon fiber cloth) both in the RF and in conventional furnace heating setup. Other advantages explored include catalyst stability, increased heating efficiency, reduced coke formation, and better heat transfer across the bed improving productivity of the entire catalyst bed.