2025 AIChE Annual Meeting

(390l) Mealworm-Based Biodegradation of Plastics: Environmental Perspective

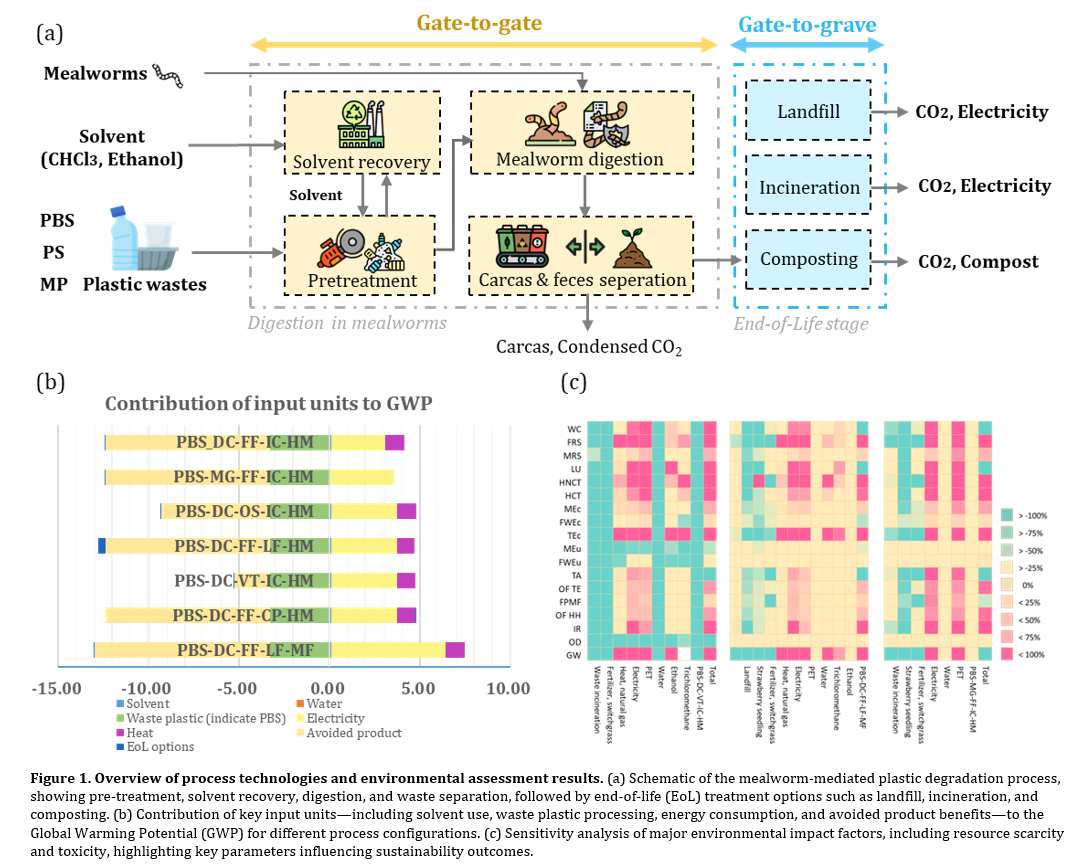

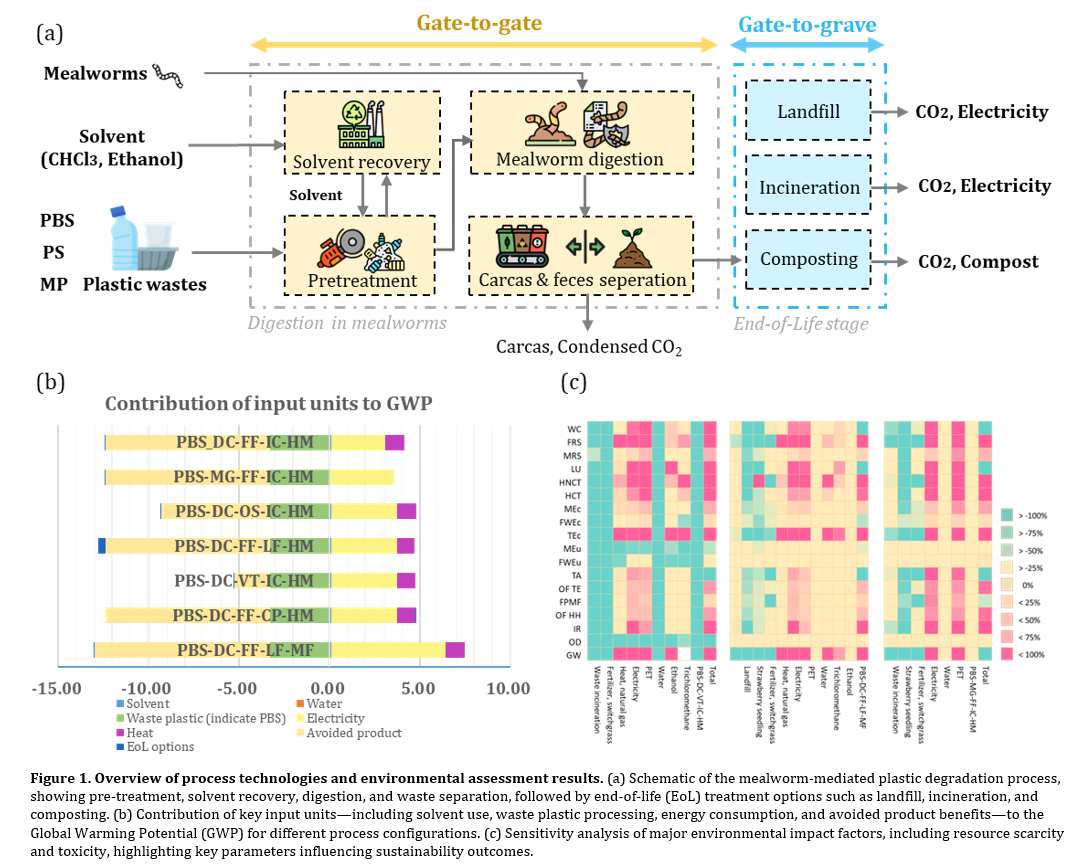

The end-of-life (EoL) phase of bioplastics remains one of the least regulated and least understood aspects of sustainable material management. While conventional petroleum-based plastics follow well-established disposal pathways such as mechanical recycling, incineration, and landfilling, bioplastics introduce greater complexity due to their highly variable degradation kinetics and material-specific waste treatment requirements. The widespread perception that bioplastics inherently reduce environmental burdens oversimplifies a more nuanced reality: the sustainability of these materials depends heavily on the specific EoL strategies employed. Bioplastics managed under inadequate or misaligned disposal methods may fail to achieve their intended sustainability benefits and, in some cases, exceed the environmental burdens of petroleum-based plastics due to slow degradation rates, unintended microplastic generation, or inefficient processing. The rapid increase in bioplastic adoption has outpaced the development of EoL treatment technologies, exposing critical gaps in waste management policies, regulatory oversight, and industrial-scale processing infrastructure. Addressing these gaps requires an innovative approach that aligns biological decomposition with existing waste frameworks while minimizing energy input and unintended emissions. Conventional EoL options for bioplastics, including industrial composting, anaerobic digestion, and enzymatic degradation, have yet to achieve the scalability and economic feasibility necessary for large-scale waste mitigation. Many industrial composting systems, for example, operate under conditions unsuitable for certain bioplastics, resulting in partial degradation or contamination of organic waste streams. In response to these challenges, this study evaluates mealworm-mediated plastic biodegradation as a pre-treatment strategy that could improve the EoL outcomes of bioplastics by integrating biological waste processing into existing waste treatment infrastructures. By facilitating preliminary degradation before subsequent waste processing steps, mealworm-mediated biodegradation offers a low-energy alternative to conventional mechanical and chemical pre-treatments, reducing both processing costs and material persistence in the environment. This study quantitatively assesses the feasibility of scaling up mealworm-based biodegradation by applying a cradle-to-grave life cycle assessment (LCA) coupled with a scenario-based evaluation of regulatory and industrial implications. The environmental assessment was conducted using SimaPro 9.1 software and the Ecoinvent 3.6 database, applying the ReCiPe 2016 midpoint (Hierarchist) methodology to evaluate key environmental indicators, including global warming potential (GWP), fossil fuel depletion, terrestrial acidification, and freshwater ecotoxicity. Design space exploration (DSE) was incorporated to explore alternative processing configurations and assess the impact of biodegradation efficiency, scalability constraints, and post-digestion waste valorization. The study modeled multiple pre-treatment and downstream processing pathways, including mechanical grinding and dry-curing as preprocessing techniques, followed by mealworm digestion and subsequent EoL treatments such as composting, incineration with energy recovery, and landfilling. The biodegradation efficiency of mealworms was evaluated based on plastic intake rates, enzymatic digestion performance, and carbon assimilation pathways. The results indicate that polybutylene succinate (PBS) exhibited substantial improvements in its net environmental impact when subjected to mealworm digestion, leading to a net GWP reduction of -8.77 kg CO₂ eq. per kg of plastic. However, polystyrene (PS) degradation exhibited high variability, with GWP values ranging from 1.02 to -5.79 kg CO₂ eq., depending on avoided product manufacturing emissions and subsequent EoL processing efficiency. These findings demonstrate that while mealworm-based degradation can provide meaningful environmental benefits, its overall efficacy is strongly dependent on material composition and downstream waste treatment strategies. A comparative analysis of conventional EoL pathways revealed that incineration with energy recovery yielded the lowest net carbon footprint (-7.23 kg CO₂ eq. per kg of plastic) due to its ability to offset fossil fuel consumption, whereas composting exhibited moderate benefits (-2.14 kg CO₂ eq.) but was constrained by high operational energy demands. Landfilling emerged as the least favorable option (4.91 kg CO₂ eq.), primarily due to slow anaerobic degradation and methane emissions. However, when mealworm-based biodegradation was introduced as a pre-treatment step, net environmental impacts across all EoL pathways improved by an additional 20-30%, indicating its potential to enhance waste treatment sustainability while reducing overall emissions. To evaluate the industrial applicability of mealworm-mediated degradation, a scenario-based policy analysis was conducted, examining its compatibility with existing waste management regulations across diverse global regions. The results suggest that countries with incineration-dominant waste systems, such as Japan and Denmark, could benefit the most from mealworm-based pre-treatment, as it reduces plastic mass and enhances energy efficiency in waste-to-energy processes. In composting-driven waste management frameworks, such as those in Germany and South Korea, mealworm frass could be repurposed as a high-nitrogen organic fertilizer, integrating biological waste processing into circular economy models. However, in landfill-reliant regions, including parts of the United States and India, mealworm degradation provides limited environmental advantages unless its implementation is scaled sufficiently to divert biodegradable plastics from landfill-bound waste streams. These findings emphasize the importance of adapting mealworm-based pre-treatment strategies to specific regional waste policies and industrial waste processing capabilities. The study further investigated key process variables affecting biodegradation efficiency, revealing that mealworm intake efficiency had the most substantial impact on overall environmental outcomes, with higher substrate consumption rates leading to greater GWP reductions. The analysis found that when mealworm intake exceeded 95% of available plastic material, net GWP reductions improved by an additional 3.2 kg CO₂ eq. per kg plastic. Additionally, controlled environmental conditions, including humidity and temperature regulation, influenced degradation kinetics by up to 40%, indicating that industrial-scale optimization could significantly enhance process performance. Beyond direct environmental benefits, mealworm-mediated degradation offers secondary sustainability advantages, including microplastic formation mitigation, reduced terrestrial acidification potential, and improved biogenic waste valorization pathways. Frass generated from mealworms fed on PBS was found to contain 5.3% nitrogen, 2.1% phosphorus, and 1.7% potassium, comparable to conventional organic fertilizers, presenting a novel opportunity for agricultural integration. This nutrient recovery potential enhances the circular economy aspect of bioplastic waste treatment, providing an additional pathway for valorizing biodegradable plastics beyond traditional waste processing. While the findings highlight the strong potential for integrating mealworm-based degradation into industrial waste management, several challenges must be addressed to ensure successful large-scale deployment. Long-term degradation kinetics, potential bioaccumulation risks, and process standardization remain key uncertainties that require further investigation. Pilot-scale trials demonstrated that mealworm colonies could process up to 2 kg of bioplastic per square meter of rearing surface per month, suggesting industrial viability under optimized conditions. Additionally, cost analyses indicated that mealworm-based degradation could be implemented at an operational expense of $0.85–1.20 per kg of processed plastic, making it economically comparable to industrial composting while offering superior environmental performance. From a regulatory perspective, this study underscores the need to integrate biological degradation pathways into standardized EoL impact assessment frameworks. Existing regulations do not adequately account for enzymatic and microbial decomposition, limiting the adoption of biological pre-treatment methods in mainstream waste processing. An analysis of 15 national waste policies revealed that only three countries currently have regulatory provisions that could accommodate mealworm-mediated degradation within formal waste classification systems. Expanding LCA protocols to incorporate biological degradation rates would provide a more accurate representation of bioplastic decomposition efficiency, guiding both policymakers and industry stakeholders in developing evidence-based waste management strategies. Furthermore, establishing industrial guidelines for mealworm-based plastic degradation would facilitate scalable deployment while ensuring process consistency, biosecurity, and compatibility with existing waste infrastructures. This study establishes a quantitative framework for assessing the feasibility of bio-mediated plastic degradation at an industrial scale, demonstrating that mealworm-based processing can substantially improve EoL outcomes for biodegradable plastics. The findings indicate that biological pre-treatment strategies could serve as a key component in future sustainable waste management policies, aligning with global carbon neutrality targets and circular economy objectives.