2025 AIChE Annual Meeting

Manufacturing and Electrochemical Assembly of CR2032 Button Batteries for Energy Storage Research

The process begins with the preparation of cathode and anode slurries, where active materials are combined with conductive additives and polymeric binders to ensure both electrochemical efficiency and mechanical stability. The slurries are subsequently coated onto current collectors, dried, and pressed to obtain electrodes with uniform thickness and optimized surface properties.

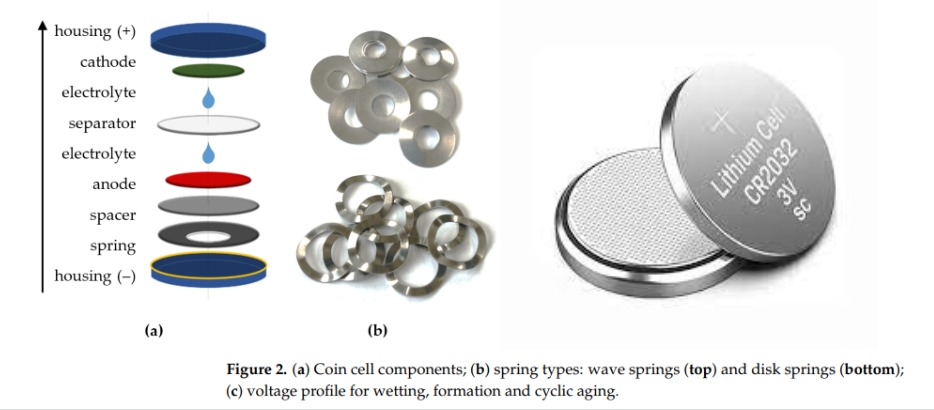

Following electrode preparation, the cell assembly stage involves the integration of cathode, anode, separator, and electrolyte within the CR2032 casing. This step requires precise stacking and sealing techniques to ensure ionic conductivity, structural integrity, and safe operation of the cell.

The outcomes of this work provide insights into the critical parameters influencing cell performance, including slurry formulation, electrode uniformity, and electrolyte infiltration. Additionally, the study addresses experimental challenges such as moisture sensitivity, handling of fine powders, and the necessity of careful laboratory practices to guarantee reproducibility and safety.

Overall, this research highlights the fundamental aspects of lithium-ion coin cell assembly, contributing to a deeper understanding of electrode fabrication and offering a foundation for further optimization in battery materials and design at both laboratory and industrial scales.