2025 AIChE Annual Meeting

(49b) Life Cycle Greenhouse Gas Emissions and Economic Assessment of Macroalgal Refineries Producing Synthetic Aviation Fuel and Value-Added Bioproducts

Authors

Jingyi Zhang - Presenter, Argonne National Laboratory

Farah Naaz, Argonne National Laboratory

Jacob Watkins, Pacific Northwest National Laboratory

Peter Valdez, PNNL

Udayan Singh, Argonne National Laboratory

Stephen Crafton-Tempel, Pacific Northwest National Laboratory

Scott Edmundson, Pacific Northwest National Laboratory

Jeff Caminiti, Pacific Northwest National Laboratory

Troy Hawkins, Eastern Research Group, Inc. (ERG)

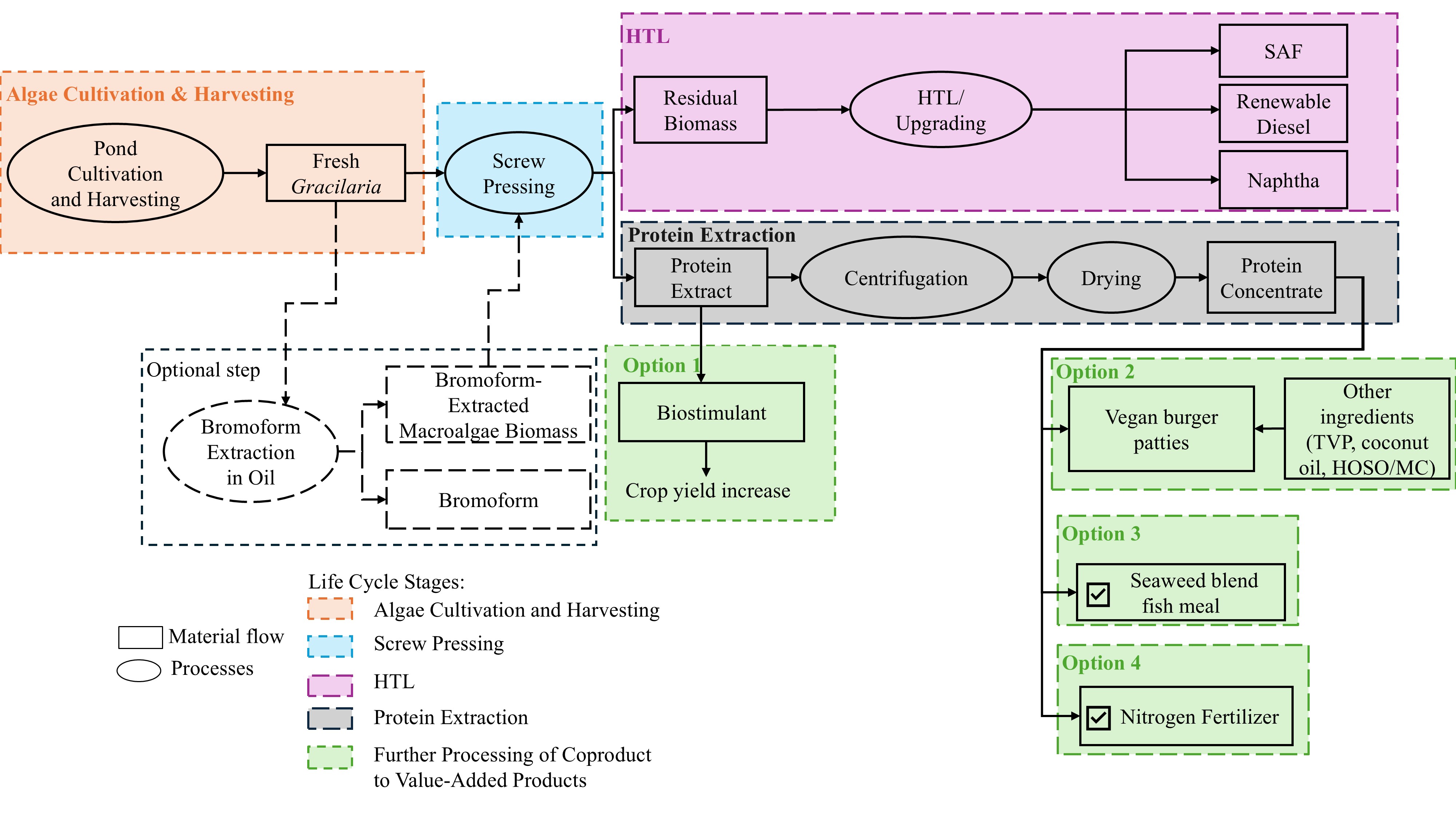

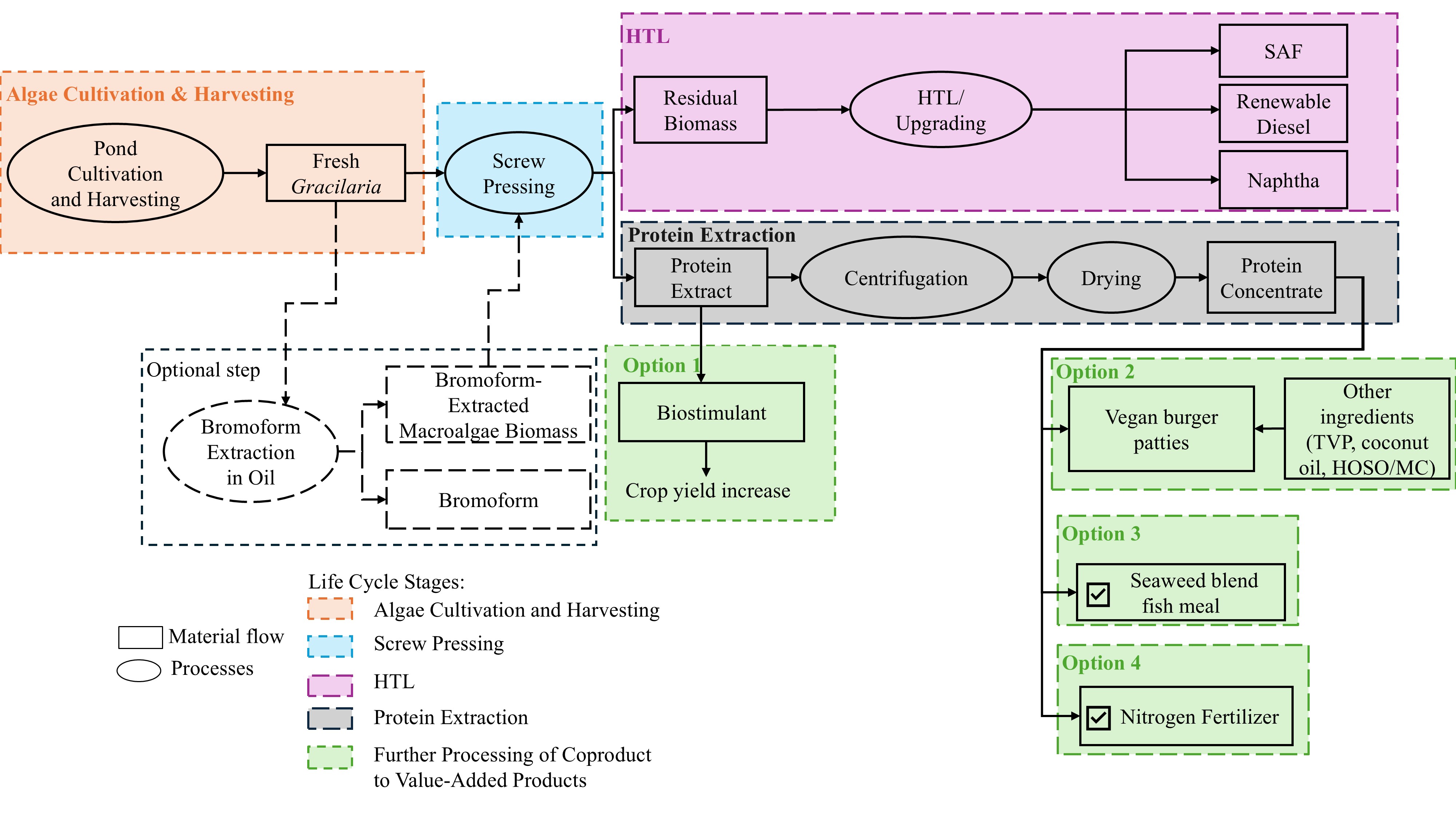

The development of saline macroalgal biorefineries that integrate high-value coproducts along with biofuel production presents a promising strategy to reduce both the cost of biofuel production and associated life cycle burdens (e.g., greenhouse gas [GHG] emissions, freshwater consumption). This study assesses the life cycle GHG emissions and economic viability of an onshore Gracilaria-based biorefinery producing synthetic aviation fuel (SAF) along with one of four screened value-added coproducts: biostimulant, vegan burger patties, seaweed-blended fish meal, or nitrogen biofertilizer (See Figure). Coproducts were selected based on compatibility with fuel production scale, market value, and potential for environmental impact reduction. Life cycle GHG emissions were quantified using the Argonne National Laboratory’s R&D Greenhouse Gases, Regulated Emissions, and Energy use in Technologies (GREET) model, applying biorefinery-level, process-level, and displacement allocation methods. An economic analysis of algae cultivation, harvesting, protein extraction, hydrothermal liquefaction (HTL), and biocrude upgrading was conducted using Algae Farm and conversion models developed at the National Renewable Energy Laboratory and Pacific Northwest National Laboratory, respectively. First-order findings show that using protein concentrate as an ingredient in vegan burger patties leads to significant GHG reductions due to the high emissions associated with conventional beef production. The ongoing work includes a full economic assessment of the macroalgal biorefinery and the estimation of marginal GHG abatement cost, which will be benchmarked against the carbon price projected by macroeconomic analysis.