2025 AIChE Annual Meeting

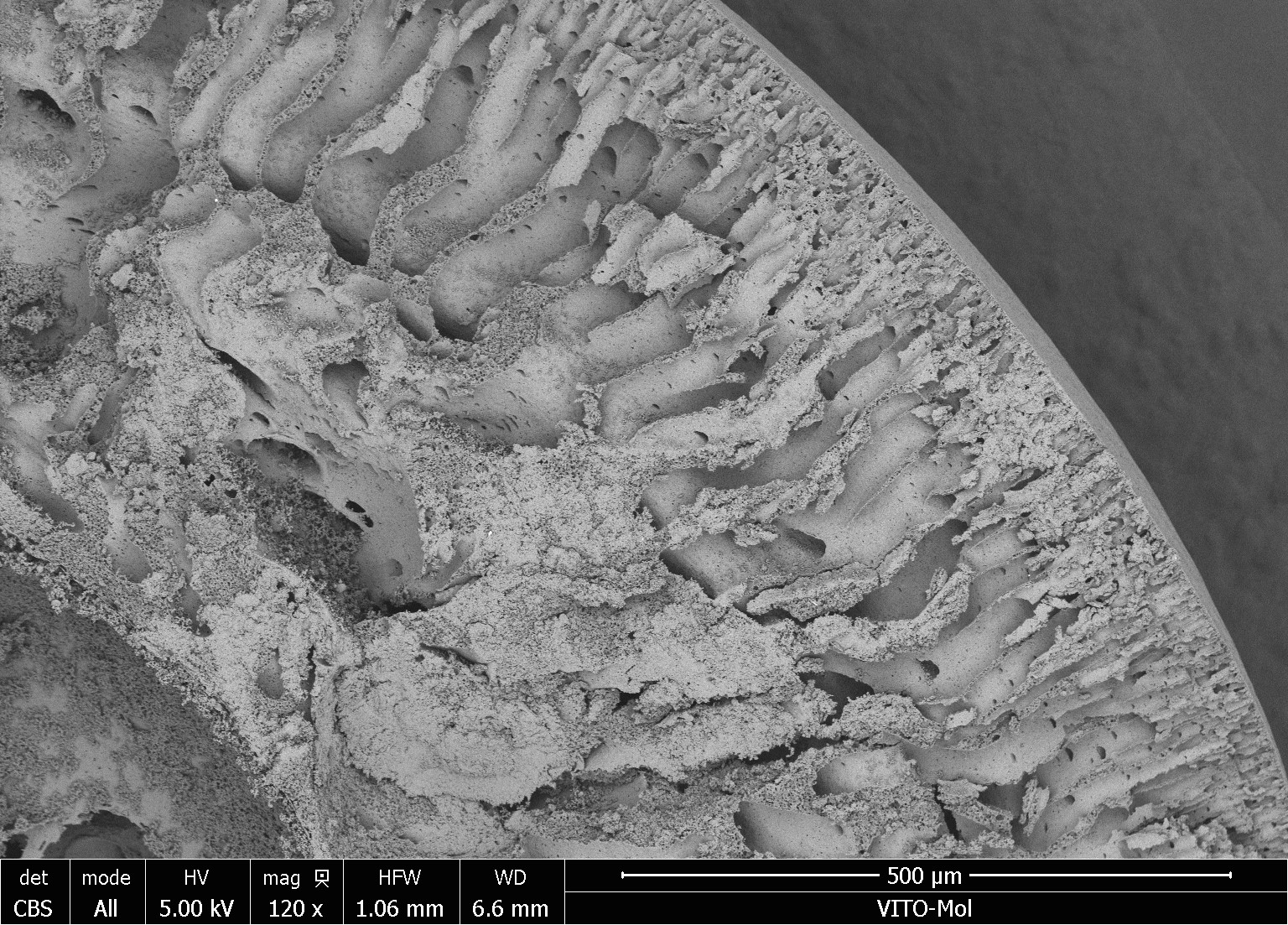

(400i) Li2TiO3/PVC Composites for Lithium Recovery from Alkaline Leachates

Selectivity tests in multicomponent systems representative of ore leachates (Li+ 0.2–0.6 g/L; Na+, K+, Ca2+ up to several g/L) demonstrated strong discrimination in favor of lithium. Separation factors exceeded 100 for Na+ and K+ and remained above 20 for Ca2+, confirming the applicability of the material to real competitive matrices. Regeneration enabled over 98% lithium recovery with no detectable Ti leaching. The composite spheres retained more than 95% of their sorption capacity after 10 adsorption–desorption cycles, demonstrating excellent stability and reusability. In tests with real spodumene leachates, the composite material maintained its performance, effectively concentrating lithium from a background of abundant alkali and alkaline earth metals. The combination of high lithium selectivity, efficient regeneration, and mechanical resilience makes these Li2TiO3/PVC composites a strong candidate for integration into direct lithium extraction (DLE) processes targeting ore leachates.

Acknowledgements: This work is supported by the European climate, infrastructure and environment executive agency (CINEA) through the project 101069644 – LiCORNE – HORIZON-CL5-2021-D2-01. Part of this work is also supported by the EIT KIC RawMaterials (EIT RM) in the frame of the OLiVer KIC Upscaling project.