2025 AIChE Annual Meeting

(391f) Investigation of the Modelling of Precipitation of Ni-Mn-Co Hydroxides.

We investigate a semi-batch precipitator applying global sensitivity analysis to determine the relevance of various crystallization processes (e.g. nucleation, growth, agglomeration and breakage) over the particle size distribution and mean particle sizes.

The mathematical model relies on the application of the population balance equation along the mass balances of the dissociated species in solution. The main assumptions of the model are:

- The precipitated crystals are spherical.

- No seeds in the initial solution or the feed are present.

- The precipitator is well mixed.

- The precipitation of individual transition metal hydroxides does not occur.

- The reaction rate of both the ionic complexes and the hydroxide formation are fast; the controlling mechanisms of the process are the nucleation and growth of the crystals.

- The crystalliser operates isothermally.

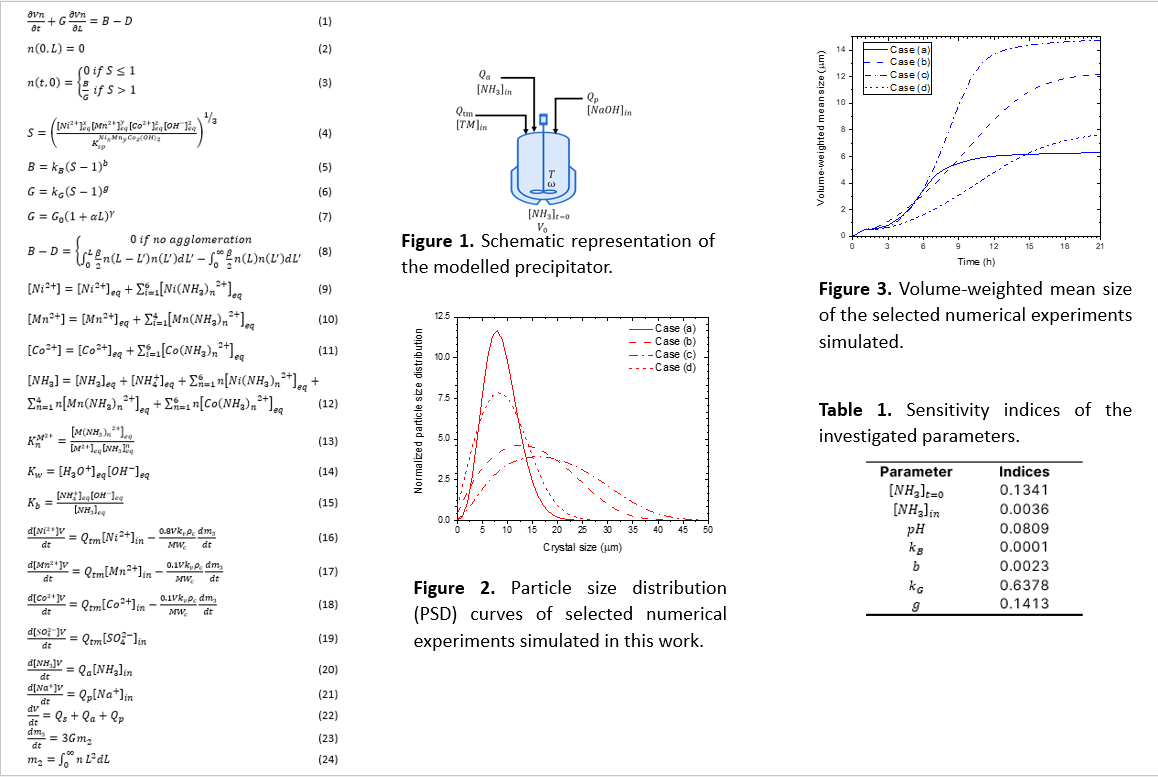

In addition, the model considered different cases regarding growth and agglomeration/breakage: size independent and size-dependent growth, no agglomeration/breakage, and agglomeration/ breakage occurring. With the previous assumptions and considerations, the model is presented by Equations (1)-(24).

The model equations were implemented and solved by the method of lines for a total of 250 simulations where the values of main operating parameters and the kinetic constants were randomly sampled using the Latin hypercube technique. Figure (2) and (3) are preliminary results of the particle size distribution and the volume-weighted particle size d[4,3] for a few selected cases among considering the model with size-independent growth and no agglomeration/breakage. The effect of the input parameters over the response of the model is visible; in general, for this case, the sensitivity indices (Table 1) obtained from GSA suggested that the model response is primarily sensitive to the growth kinetics, the solution pH and the initial concentration of ammonia. Less relevant is the kinetics of nucleation, whereas the concentration of ammonia feed seems to be irrelevant. Next steps are to analyse the effects of size-dependent growth, and agglomeration/breakage.