2025 AIChE Annual Meeting

(289e) Investigation of Blend Time for Turbulent Newtonian Fluids in Stirred Tanks: A Fourth and Hopefully Final Analysis

A blend time investigation for stirred tanks was conducted to study the effect of impeller diameter (D = T/2, T/3, and T/5), impeller off-bottom distance (C = T/2, T/3, and T/5), and impeller type (A310 Hydrofoil, Pitched-Blade Turbine, and Rushton Turbine) while considering tank diameter (T = 0.61 and 1.22 m) and mean specific energy dissipation (ε = 0.005 and 0.01 W/kg) for fully turbulent Newtonian fluids. The response of conductivity probes to the injection of a saturated NaCl tracer was monitored to experimentally measure blend time for 108 unique configurations produced by a full factorial experimental design.

The results of the experimental blend time measurements have been analyzed three times previously to determine trends and develop correlations with each analysis providing new insights. The first analysis sought to test the hypothesis of power-based, impeller-independent blending theory and was published as the presenter’s master’s thesis “Investigation of Blend Time for Turbulent Newtonian Fluids in Stirred Tanks” and was presented at the 2017 AIChE Annual Meeting. This first analysis validated that a universal blend time correlation could be derived using the entire data set as a whole and was compared to the currently accepted FMP/Grenville correlation.

The second analysis investigated and further tested the theory of impeller independence by analyzing each impeller’s data set separately. Unique and statistically significant blend time correlation coefficients were determined for the A310, PBT, and Rushton impeller types. This expansion of work was presented at NAMF’s Mixing XXVI conference in 2018.

The third analysis sought to further test the theory of impeller independence and to develop a more statistically robust correlation by using the entire data set to fit a single correlation with a term to delineate impeller type. However, during that analysis, a power number measurement error was identified that impacted 36% of the data set. This error was due to low torque loading on the torque cell used for power measurement and was the result of trying to span the entire DOE (i.e., across 2 scales and 3 D/Ts) with a single torque cell to limit instrumentation variation. This discovery was presented at NAMF’s Mixing XXVII conference in 2024 and necessitated remeasurement of power number for the impacted cases.

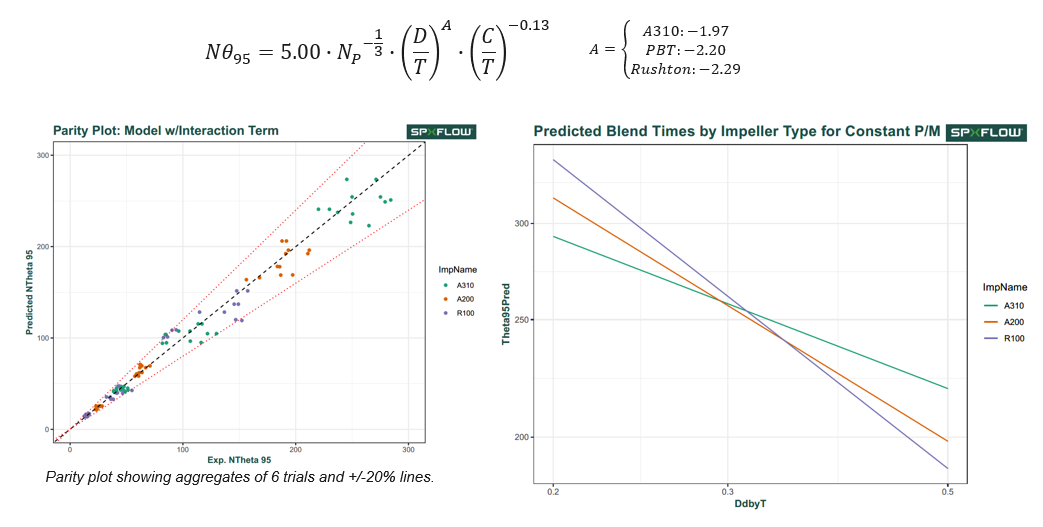

The power number remeasurements and a fourth analysis of the experimental data have been completed and prepared for presentation at AIChE’s 2025 Annual Meeting. The method and results of the power number remeasurements will be discussed. The results of the fourth analysis effort and correlation development will be discussed. The final correlation and parity plot against experimental measurements is shown in the attached abstract image. The results of the fourth analysis demonstrate evidence of impeller type dependence on turbulent blend time in stirred tanks and indicate universal power-based blend time theory (while derivable and able to be correlated) may be erroneous. The implications of impeller type dependence on turbulent blending will be discussed, and the attached abstract image includes a dimensionless blend time versus D/T chart for the 3 impeller types that begins to illustrate implications of impeller dependence blending theory. The trade-offs between minimizing capital cost, minimizing operating cost, and maximizing blending performance will be discussed.