2025 AIChE Annual Meeting

(289b) Investigating the Effect of Agitator Geometry and Fluid Rheology on the Performance of Sawtooth Impellers

Authors

Sawtooth impellers are a common type of high-shear mixing element used in industrial paste processing such as the manufacture of paints, pastes, etc. Previous work on sawtooth impellers has explored the effects of rotational speed and scale. However, work on sawtooth impeller geometries is limited to the prefabricated discs available commercially [1,2]. As such a fundamental understanding of key geometry parameters of the disc and teeth, and the effect of such variations on power draw and fluid flow profiles has not yet been explored.

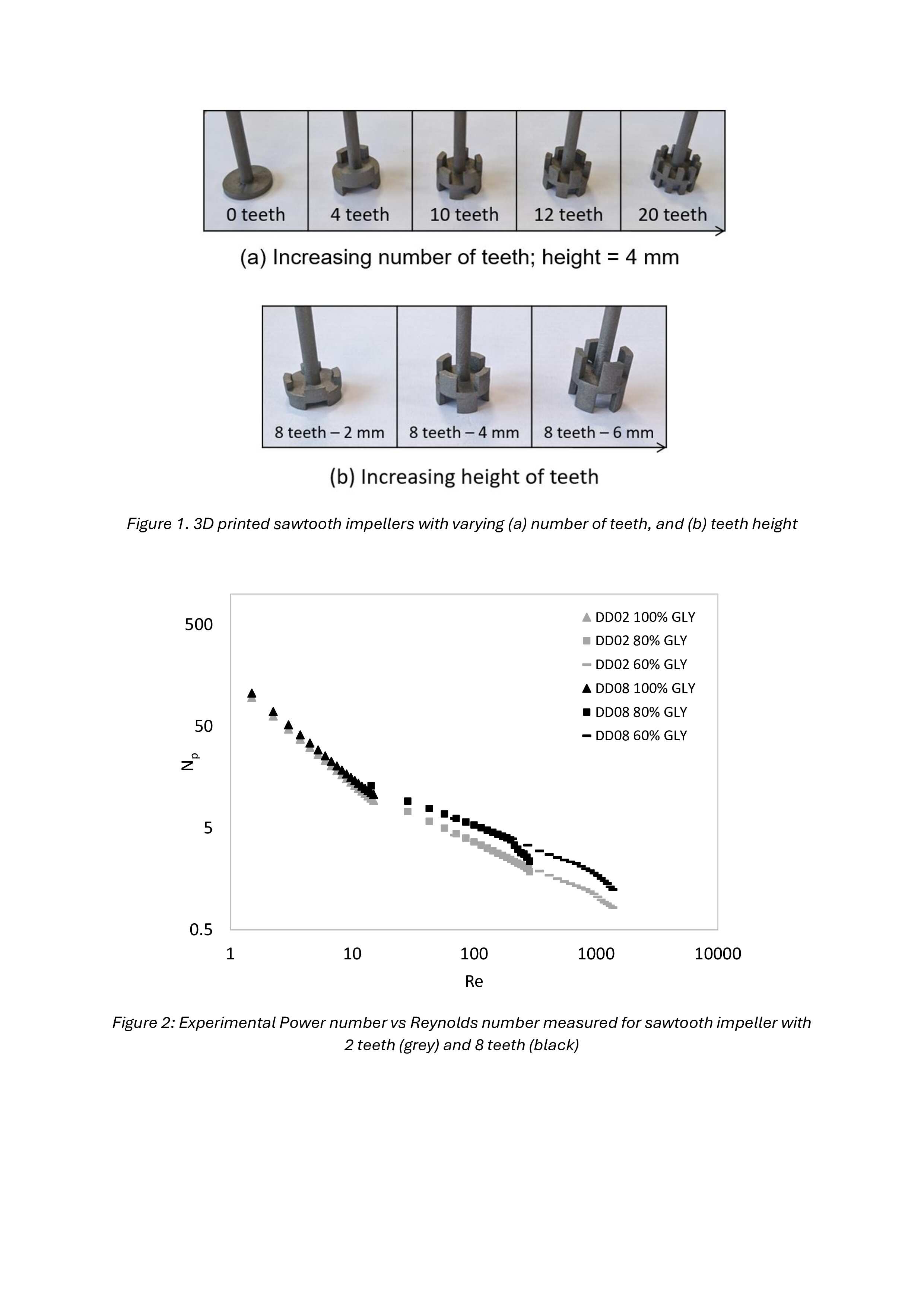

The present research aims to bridge this knowledge gap by applying experimental and computational techniques to investigate the effect of geometry on the power draw characteristics of sawtooth impellers at the same scale, including fluid rheology as a considered factor. This was achieved by means of a scaled down experimental set-up, where 12 custom geometries of sawtooth impellers varying in the number and height of teeth (rectangular and evenly spaced) were 3D printed (Figure 1).

The 3D printed geometries were installed in a rotational rheometer fitted with a cylindrical cup containing the fluid. The fluid fill height was set equal to the cup diameter and the bottom clearance was set such that the disc was positioned at 1/3rd of the fill height. Torque was recorded as a function of rotational speed for fluids demonstrating different rheological properties [Newtonian – glycerol (0.954 Pa s) and glycerol solutions (60 - 90 wt.%; 0.009 – 0.157 Pa s), and shear-thinning non-Newtonian fitted to a power law model – Carbopol solution (1.5 wt. %; consistency index K = 124 Pa s, flow behaviour index n = 0.12) and Xanthan solution (5 wt. %; consistency index K = 43 Pa s, flow behaviour index n = 0.20)].

The torque response increased as a function of tip speed and apparent viscosity, whereby the extent of increase was greater for fluids possessing higher apparent viscosity. At fixed tip speed the impeller torque increased when the number of teeth was increased from 0 to 8 teeth. Further increase in number of teeth had a diminishing effect.

Data from the Newtonian systems studied were used to examine the relationship between the dimensionless Power number, Reynolds number, and Froude number. Experimental results show a smooth curve for the Power number against the Reynolds number at lower rotational speeds. While the Power curve for the different geometries overlapped in the laminar regime, an upward shift was observed in the transition to turbulent regime (Re ≥ 20) as a function of increasing number of teeth at the same scale (Figure 2). A steep reduction in the Power number at high rotational speeds was also observed, attributed to the deformation of the free surface vortex [3].

Torque data collected for the non-Newtonian fluids was used to calculate the Metzner-Otto constant for the geometries using methodology from Delaplace et al. [4]. Fitting the Carbopol gel torque data to the power curve established for each geometry shows that a linear relationship between the effective shear rate and rotational speed holds for low rotational speeds (N < 15 rps), although not for the full range of rotational speeds in the laminar regime. This gives further insight into the applicability of the widely used Metzner-Otto constant in mixing process industries. The dependence of the Metzner-Otto constant on the geometry parameters of the impeller was not found to be significant in the range of rotational speeds to which it could be applied.

Computational fluid dynamics (CFD) models of the set up were produced and validated against the experimental data collected, and further used to complement the understanding from the experiments. The mass and momentum conservation equations were solved in a finite volume framework and a rotating reference frame method was used to obtain fluid flow profiles and torque values for steady state flow at a given tip speed.

The CFD generated fluid flow profiles show the fluid velocity in between the teeth and in the immediate vicinity of the impeller. At a fixed rotational speed and horizontal plane, the azimuthal fluid velocity between the teeth (normalised against the maximum azimuthal fluid velocity) increases as the number of teeth increase. This is attributed to the reduction of space in between the teeth, and suggests that the fluid between the teeth rotates as a solid body with the teeth, with reduced radial or axial movement. This was used to rationalise the torque response to impeller rotation increasing with the number of teeth up to a maximum point, beyond which the rate of increase in torque plateaus.

Additionally, the effect of increasing tip speed and fluid rheology was also considered. Flow profiles for the non-Newtonian Carbopol gel were used to investigate the outcomes of the Metzner-Otto analysis of the experimental data. Flow profiles within the range of rotational speeds where the Metzner-Otto can be applied were compared to flow profiles for higher rotational speeds. The onset of recirculation patterns close to the impeller geometry at higher rotational speeds was assessed in this context.

Flow visualisation provides deeper insight into the flow profiles in the vicinity of the mixer geometry and reveals shear rate profiles as a function of tip speed and impeller teeth. This information will be useful in further studies on the scale-up of sawtooth impellers and their performance within multiple impeller systems. Understanding such flow dynamics is crucial for optimising mixer design and improving efficiency in industrial applications.

References:

- Oğla, B., Gürçay, Ö. and Helvacı, Ş.Ş., 2023. Power draw characteristics and comparison of scaling criteria for sawtooth impellers used in high shear mixing of shear thinning paint slurry. Chemical Engineering Research and Design, 189, pp.210-219.

- Paul, E.L., Atiemo-Obeng, V.A. and Kresta, S.M., 2004. Handbook of industrial mixing (pp. 1-143). New York: Wiley-Blackwell.

- Scargiali, F., Tamburini, A., Caputo, G. and Micale, G., 2017. On the assessment of power consumption and critical impeller speed in vortexing unbaffled stirred tanks. Chemical Engineering Research and Design, 123, pp.99-110.

- Delaplace, G., Jeantet, R., Grenville, R., Cuvelier, G. and Loubiere, K., 2022. How dimensional analysis allows to go beyond Metzner–Otto concept for non-Newtonian fluids. Reviews in Chemical Engineering, 38(4), pp.407-429.