2025 AIChE Annual Meeting

(639e) Inverse Design of Bimetallic Catalysts for Hydrogen Generation Via Ammonia Cracking

Authors

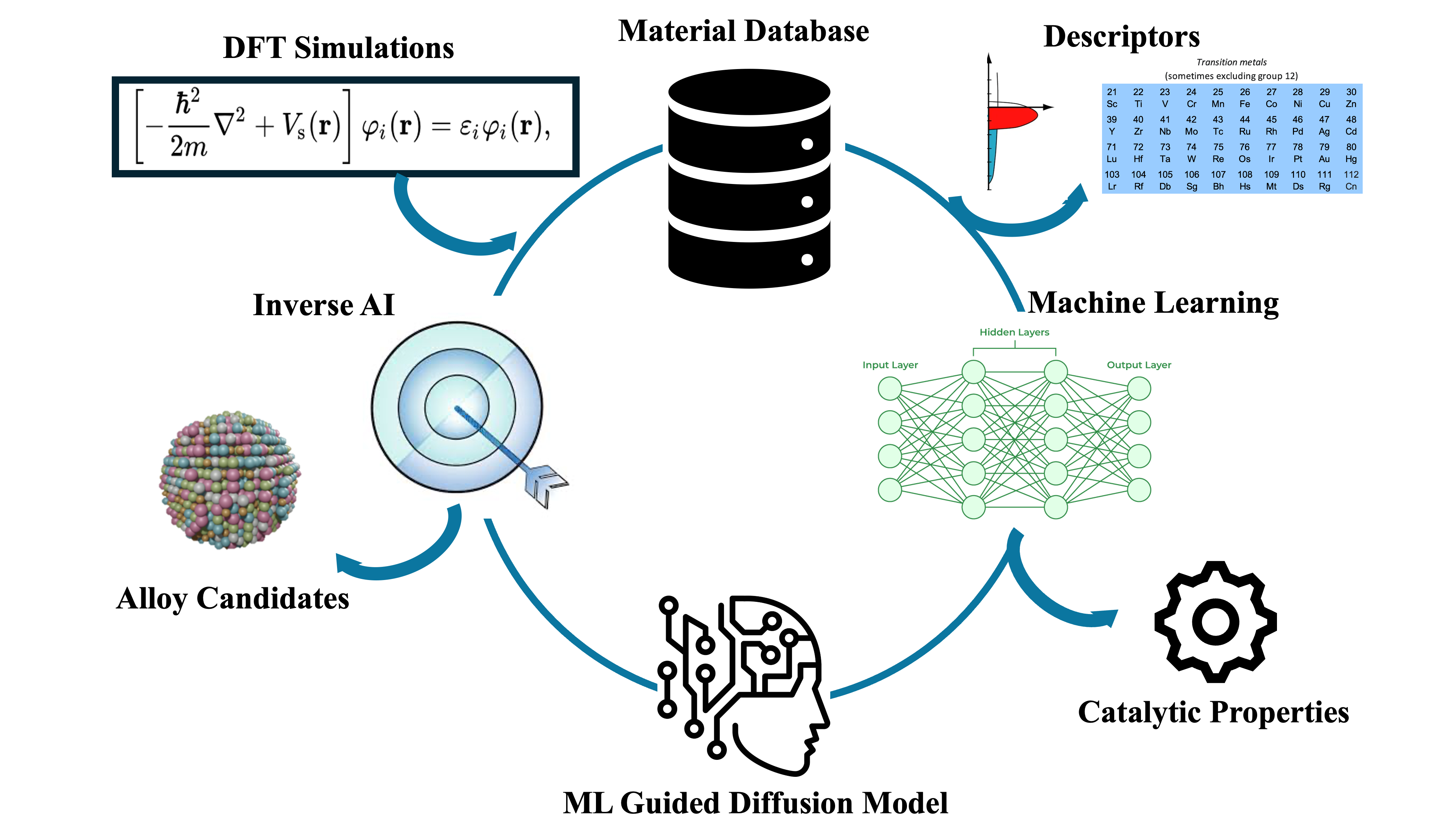

The diffusion model, a state-of-the-art generative ML technique, has found widespread application in AI-driven generation of images, molecules, and material structures. In this study, we developed an ML-guided diffusion model workflow to design earth-abundant bimetallic alloy catalysts for ammonia cracking reaction. The training dataset consists of DFT-simulated surface properties, electronic properties, and adsorption energies for over 2,000 bimetallic alloy compositions and configurations. A predictive ML model was trained to estimate nitrogen adsorption energy, a key catalytic descriptor for ammonia cracking, based on microkinetic modeling, of newly generated bimetallic samples. The inverse design diffusion model, built upon this dataset and predictive model, generates novel bimetallic alloy configurations while incorporating physical constraints and performance guidance. During each generation step, the predictive ML model provides feedback, rewarding the diffusion model for improved nitrogen adsorption energy. The most promising candidates were validated using DFT calculations and catalytic ammonia cracking kinetic experiments. We identified CoFe, NiFe, and 14 other bimetallic alloys that exhibit significant catalytic advantages for thermal ammonia cracking, validated by the experiments. Our ML-guided inverse design diffusion model offers a highly efficient and resource-conserving approach for cost-effective catalyst and material design, with reduced computational demands compared to traditional methods.