2025 AIChE Annual Meeting

(648e) Intra-Slug Mixing Enhancement in Milli-Fluidic Liquid-Liquid Flow Systems Via Contact Angle Modification

Authors

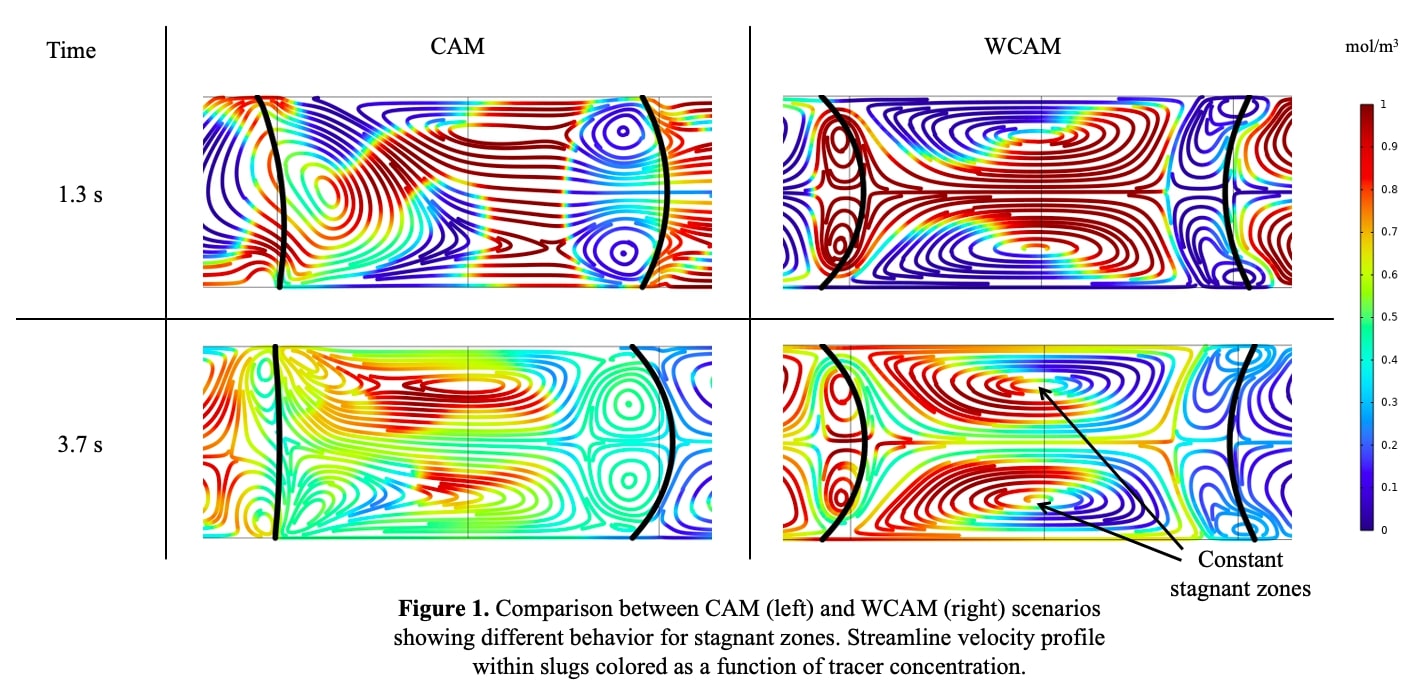

A series of computational fluid dynamic (CFD) simulations were performed to assess the effect of contact angle modification (CAM) in intra-slug mixing. The simulations consisted of a Lagrangian specification of field of a slug moving through a 2 mm channel that experiences a stepwise modification of the contact angle at a frequency of 1.3 s-1. The shape of the interface will adjust accordingly to the surface wettability (hydrophobic to hydrophilic and vice versa). A tracer with a concentration of 1 mol/m3 was introduced to the front half of the slug relative to the direction of motion, whereas the other half contained the same liquid phase without the tracer. The performance of the system was estimated by defining the intra slug-mixing index as Eq. 1.

Imix = 1 - (αt / α0), (1)

where αt and α0 are the standard deviations of the concentration profiles at a time t and time 0 s, respectively. A Imix = 0 indicates complete segregation (no mixing), while a Imix = 1 indicates a fully mixed system. The Imix of the CAM simulations were compared to a system without a modification in the contact angle (WCAM). Both simulations consider a slug with a fixed length and a constant flow rate (1 mL/min).

Results suggest that the strategy of CAM could improve the Imix due to the disruption of the constants stagnant zones (circulation patterns) inherent to Taylor flow within the slug (as seen in the figure attached) which would otherwise remain undisturbed. This disruption was observed as a result of a change in the slug interface shape that locally accelerates (transition from convex to concave interface) and decelerates (transition from concave to convex interface) the solute within the slug. As a result, by implementing CAM a 54% increase in Imix is obtained at 1.3 s, while a 46% improvement takes place at 3.7 s.

This passive technique effectively reduces concentration gradients (attached figure, t = 3.7 s) while comparing CAM and WCAM systems. Similar results could be achieved by the geometrical modification of the channels that alter the circulation patterns within the slug. However, this strategy could lead to a better distribution of the solute within the slug without requiring any geometrical changes to the system and without advanced manufacturing techniques for lower volumes and flow rates. CAM offers a simple yet effective way to enhance continuous chemical and biological processes.