2025 AIChE Annual Meeting

(705a) Interpretable Machine Learning-Guided Plasma Catalysis for H2 Production from NH3

Authors

Shengyan Meng, Dalian University of Technology

Charles Milhans, University of Massachusetts Lowell

Magda Barecka, Cambridge Center For Advanced Research and Educati

Yilang Liu, University of Massachusetts Lowell

Qiang Li, University of Massachusetts Lowell

Jiaqi Yang, University of Massachusetts Lowell

Yabing Sha, University of Massachusetts Lowell

Yanhui Yi, Dalian University of Technology

Fanglin Che, University of Massachusetts Lowell

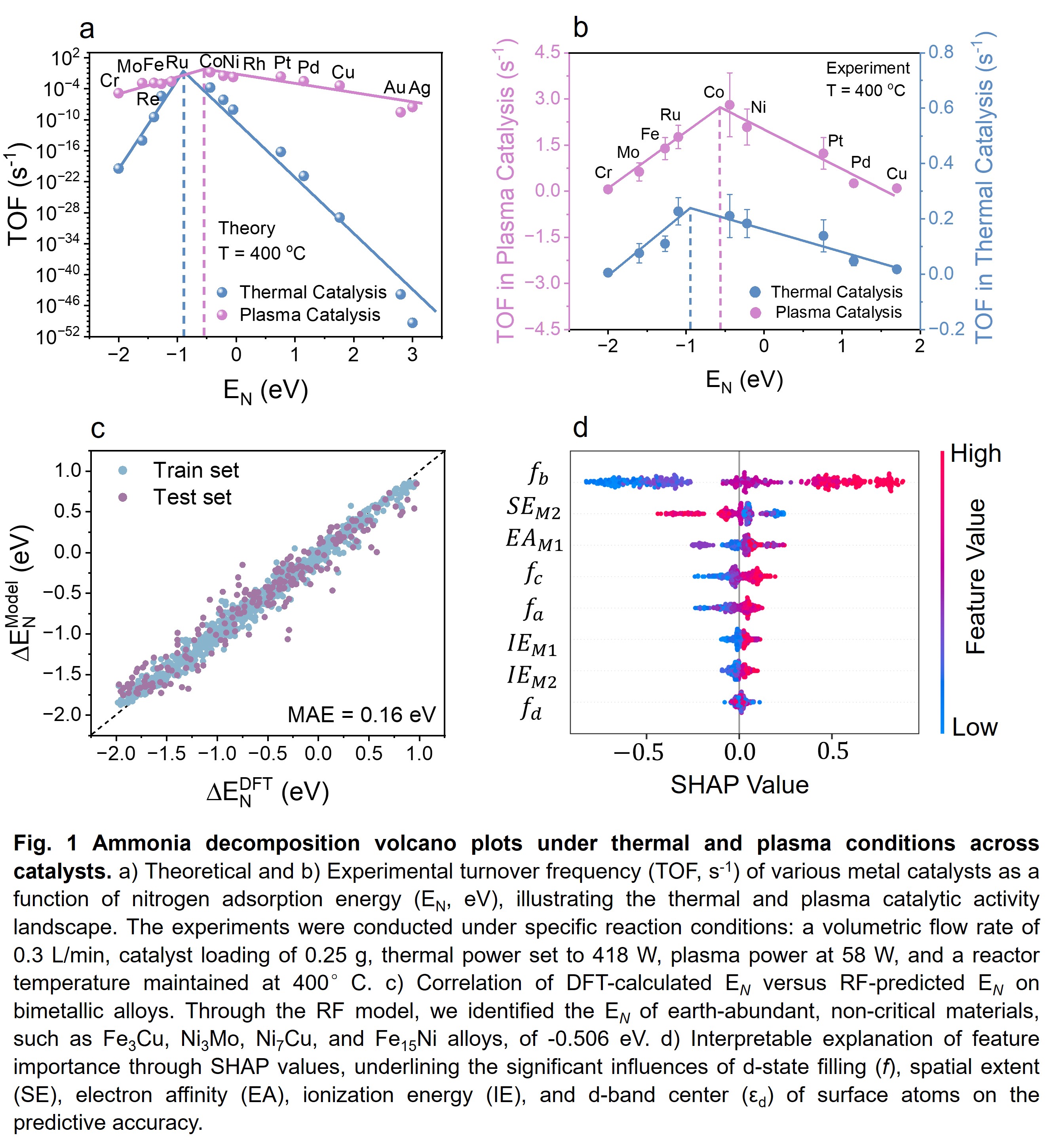

Hydrogen (H₂) is a key energy carrier for decarbonizing the transportation sector, but its large-scale adoption is hindered by storage and transport challenges.1 Ammonia (NH3) offers an energy-dense and carbon-free alternative for H2 storage and transportation.2 However, conventional NH3 decomposition requires high temperatures (>773 K) and noble metal catalysts such as Ru, raising cost and sustainability concerns.3 To overcome these limitations, we integrated non-thermal plasma (NTP) catalysis with interpretable machine learning (ML) and multi-scale simulations to design cost-effective, earth-abundant catalysts for NH3 decomposition under mild conditions. Our study demonstrates that under NTP conditions, Co exhibits superior catalytic activity (Figs. 1a-b) compared to Ru under conventional heating. By employing density functional theory (DFT)-based microkinetic modeling and ML-assisted catalyst screening, we identified nitrogen binding energy (EN ) as the key descriptor governing NH3 decomposition rates. Using this insight, we screened over 3,300 bimetallic compositions and discovered highly active catalysts such as Fe3Cu, Ni3Mo, Ni7Cu, and Fe15Ni, which outperformed their monometallic counterparts in experimental validations. The Random Forest model (Fig. 1c) has the highest accuracy, optimizing at 48 trees with a mean absolute error of 0.16 eV. SHAP value analysis (Fig. 1d) indicated the d-band filling of alloy surface atoms was the most influential factor in EN predictions. Our techno-economic analysis further supports the viability of plasma catalysis for on-site hydrogen production, achieving a hydrogen production cost below $1/kg H2 and a reduced carbon footprint of ~0.91 kg CO2 per kg H2. These results establish machine learning-guided plasma catalysis as a scalable and cost-effective strategy for sustainable hydrogen generation.

References

- Griffiths, S. et al., Global Energy, 2022, 28, 46-58.

- Hansgen, D. A. et al., Nature Chemistry, 2010, 2, 484-489.

- Bayer, B. N. et al., Plasma Chemistry and Plasma Processing, 2024, 1-18.