2025 AIChE Annual Meeting

(362d) Impact of Coating Process Parameters on Tablet Bed Environment and Coating Quality

Authors

target/controlled release, taste masking, etc). A typical coating operation includes spraying aqueous

coating solution onto the hot tablet surface, with tablets tumbling in a perforated pan, with hot inlet

air drying off the water from the tablet surface, leaving behind a layer of pigments and other coating

material. The coating process parameters play a vital role in determining critical quality attributes

such as description and release, however, differences in equipment design and operator-specific

variables, such as baffle/spray nozzle designs, air flow pattern, spray angle, sensor locations etc.,

make technology transfer from small to pilot-scale equipment extremely challenging. Hence, the

study aims to characterize the local tablet bed conditions and leverage it as a scale-independent

variable across different equipments. The study is focused on: 1) highlighting differences between

thermodynamic predictions and tablet bed measurements, and 2) relating local tablet bed

conditions to coating defects to identify, characterize, and define the ideal coating design space.

Methods: This study involved coating placebo tablets (primarily composed of microcrystalline

cellulose) using common processing equipments, including the Flex 05 and Flex 100 pan coater

(Thomas Processing, Elgin, IL). The tablet bed temperature and humidity conditions were monitored

using penny-sized sensors known as ibuttons (iButtonLink Technology, Whitewater, WI). Tablet

surface temperature was also tracked using an IR thermometer gun, while tablet surface humidity

was measured via water activity. Spray rate, gun-to-bed distance, pan speed and tablet load were

analyzed to understand their impact on tablet bed conditions. The tablet coating quality was

assessed using surface roughness measurements.

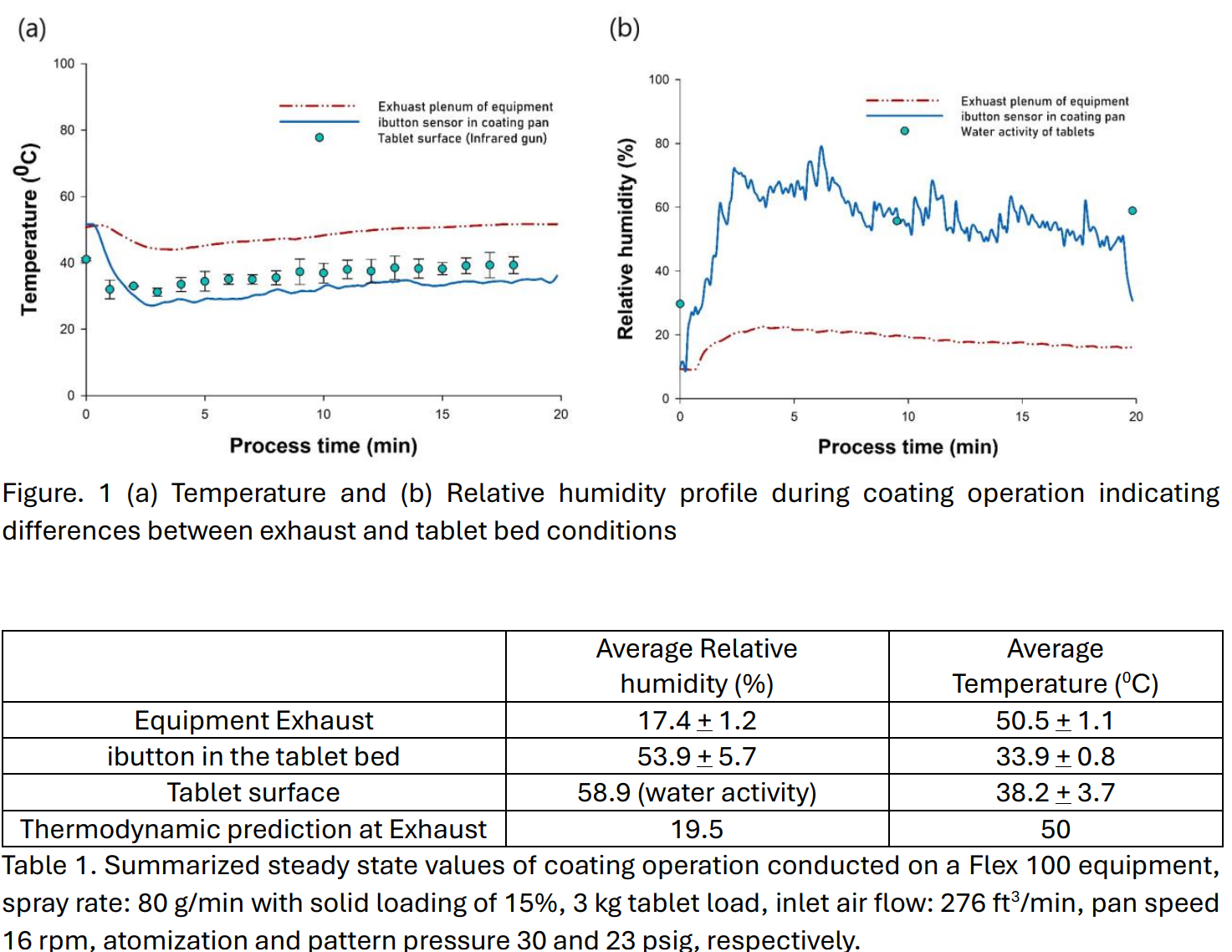

Results: An example of differences between thermodynamic modeling and local tablet conditions

is highlighted in Figure 1. The tablet bed temperature consistently remained below the exhaust

temperature (Figure 1(a)), owing to the evaporative cooling effect of the coating formulation,

consistent with prior research [2]. The tablet bed relative humidity spiked with the onset of spray

(Figure 1(b)). High local relative humidity (~55%) negatively impacted coating quality as depicted in

Figure 1(c). The rough surface coating was quantified through arithmetical mean height, Sa and

maximum height, Sz. The tablets had high Sa and Sz values (Sa = 3.019 µm, Sz = 38.7 µm), indicating

a relative rougher surface texture and hinting of coating defects and logo bridging. Summary results

of steady-state temperature and humidity are in Table 1.

Conclusion: Our findings reveal a correlation between ibutton sensor measurements and tablet

surface temperature and water activity. Notably, deviations from exhaust/thermodynamic conditions

were noted under high spray rate conditions, underscoring the importance of operating parameters

and local tablet bed conditions in critically influencing coating quality.