2025 AIChE Annual Meeting

(584cc) Hydrocracking of PVC-Mixed Polyolefin (PO) over Bifunctional Tungsten-Carbide (WxC) Catalysts

Authors

Uchenna Nwachukwu - Presenter, The University of Akron

Mattew Moegling, THE UNIVERSITY OF AKRON

Sinhara Mudalige Hasitha Perera, University of Rochester

Marc Porosoff, University of Rochester

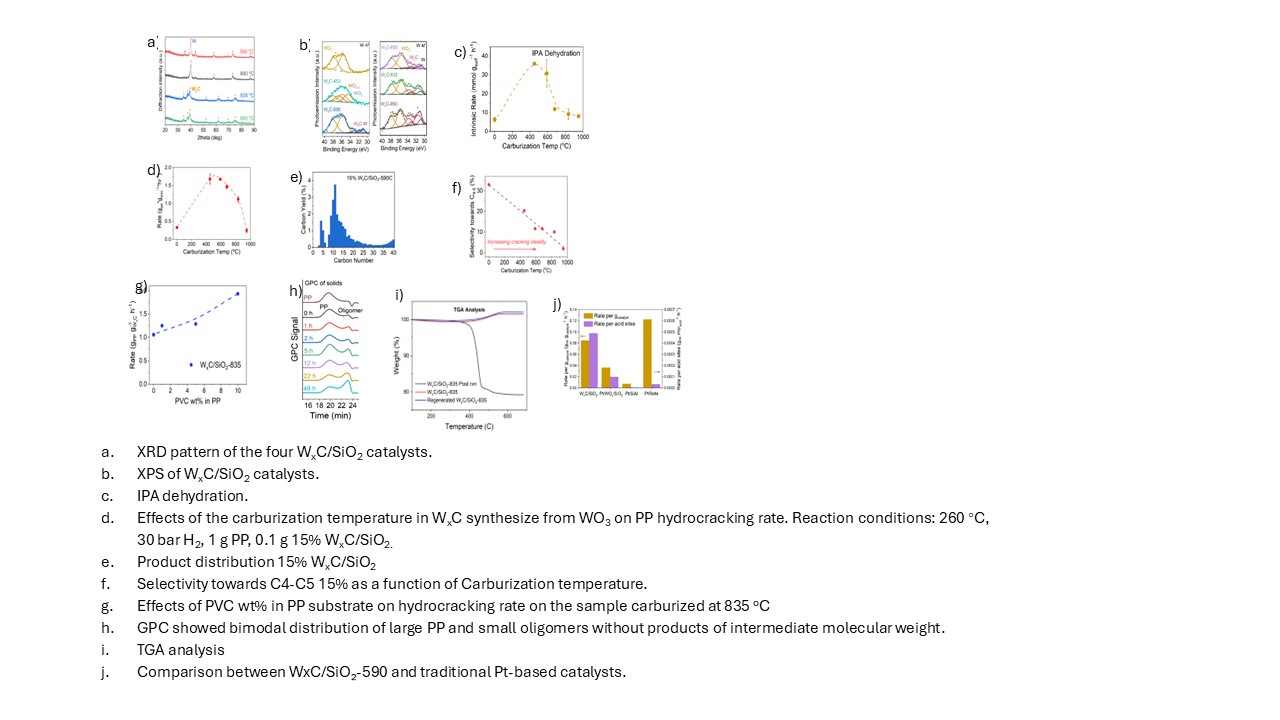

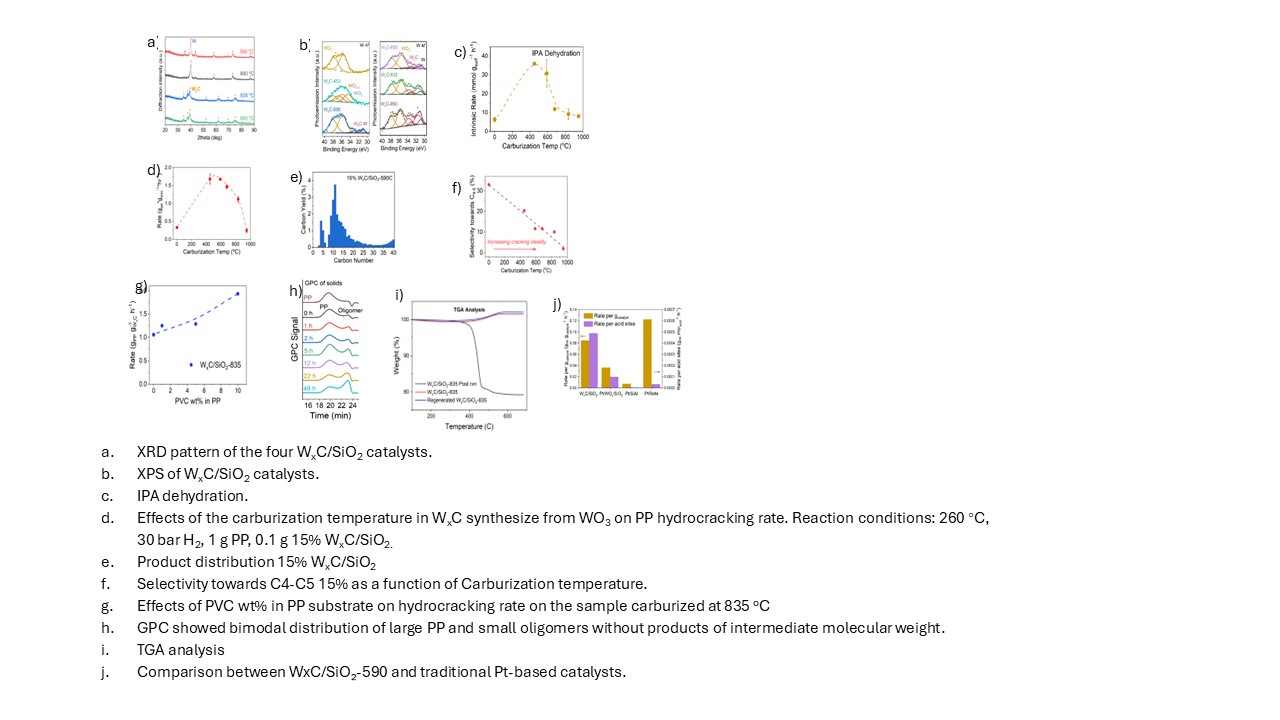

Linxiao Chen, Cornell University

The global plastic waste crisis continues to escalate due to the widespread use of polyolefins (POs) in packaging, consumer goods, and industrial applications. Most of the polyolefin plastic waste remains unprocessed, leading to environmental pollution and inefficient resource utilization. Hydrocracking converts polyolefins into valuable hydrocarbons using bifunctional catalysts that combine metallic sites for (de)hydrogenation and acid sites for carbon-carbon bond scission. The reaction faces issues in catalyst deactivation by poly-vinyl chloride (PVC) in mixed plastics and slow polymer diffusion between metallic and acidic active sites. This study explores tungsten-carbide (WxC) catalysts as an efficient, PVC-compatible, cost-effective alternative to noble-metal/zeolite hydrocracking catalysts. Characterization results revealed that with rising carburization temperature (Tcarb), W/W₂C phases that provide “metallic” function are formed (Fig. a). An initial increase followed by a decrease in acidic sites is observed, alongside a continuous rise in metallic sites (Fig. b-c). Kinetic studies show that as Tcarb increases, the reaction rate exhibits a volcano-shaped curve explained by the requirement of balance between metallic and BAS (Fig. d). C3-40 hydrocarbons were produced without undesired C1 and C2, as expected for bifunctional hydrocracking (Fig. e). As Tcarb increases, the selectivity towards C4-C5 reduces, i.e., the ideality of hydrocracking increases with more “metallic” sites relative to BAS (Fig. f). Fig. g shows that WxC is tolerant to at least 10 wt% PVC. The rate increase with PVC addition is caused by the enhancement of BAS with HCl adsorption from PVC. Bimodal distribution of large PP and small oligomers without intermediates was observed from GPC (Fig. h), suggesting the sequential cleavage of each PP chain. Coke was detected on the catalysts by TGA, but completely removed to regenerate the activity with a simple H2 treatment (Fig. i). Compared to conventional hydrocracking catalyst, WxC/SiO₂-590 shows significantly higher activity per acid site, highlighting its high efficiency.