2025 AIChE Annual Meeting

(392x) Hybrid Mechanistic Game-Theoretic Design for Resilient Hydrogen Supply Chains Under Uncertainty

Authors

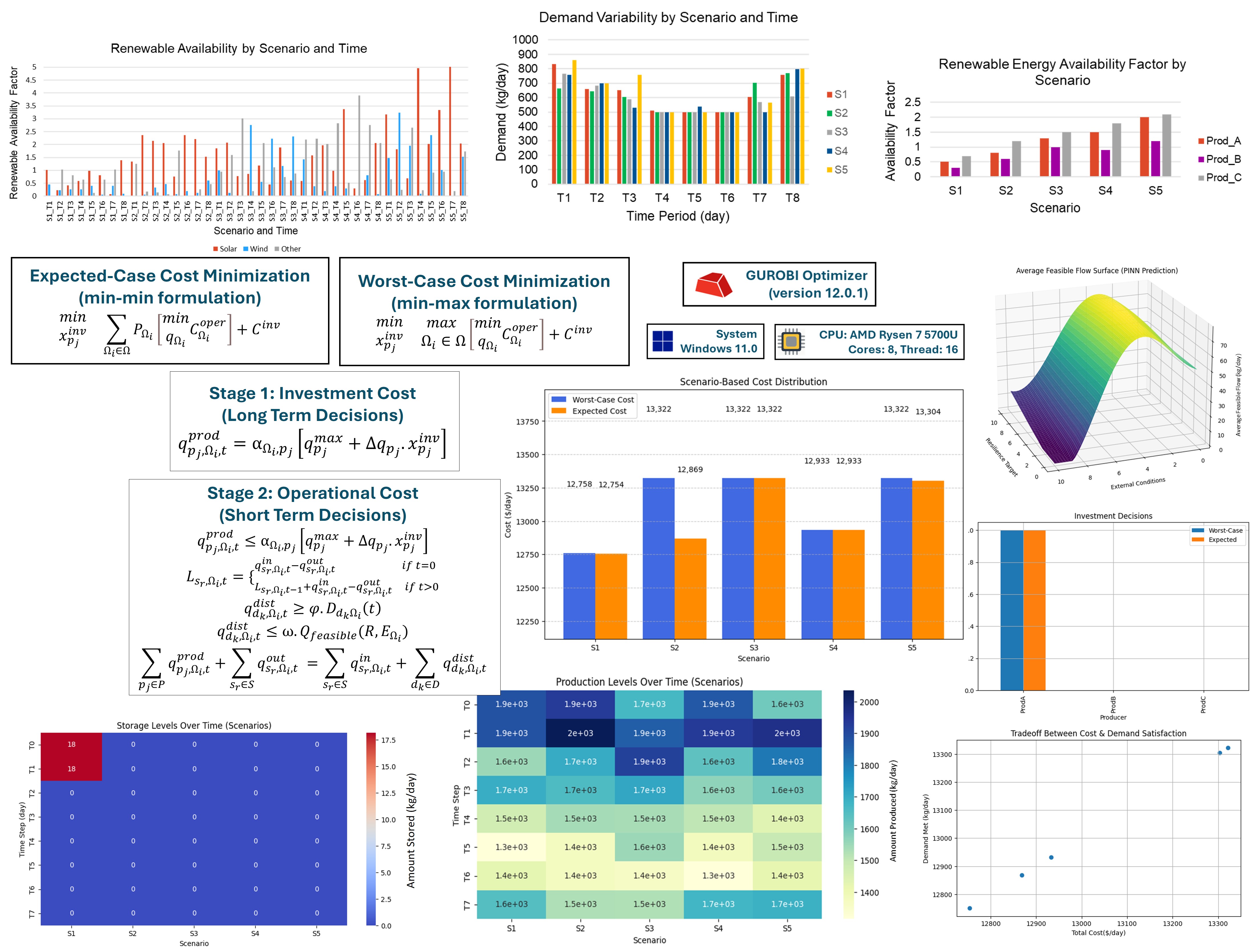

The framework employs a two-stage structure. The first stage uses cooperative game theory to guide long-term strategic investments such as capacity expansions and storage deployment, aligning stakeholders around shared resilience goals through pooled resources and infrastructure co-investment. The second stage handles real-time operational adaptation using non-cooperative game theory, where producers, storage operators, and distributors respond to dynamic supply-demand shifts and renewable fluctuations. These interactions are stabilized through equilibrium strategies, forming a self-correcting and robust network. A key innovation is the use of IPINNs, which integrate physical constraints—such as pipeline flow limits and resilience requirements—into neural network predictions. Trained with a hybrid loss function that combines data fidelity and physics-based constraints (e.g., the Darcy-Weisbach relationship), the IPINNs generate physically consistent flow boundaries that feed directly into the optimization model. Post-processing further refines flow predictions using nonlinear transformations incorporating resilience decay and external condition modulation. The model is formulated as a Mixed-Integer Nonlinear Programming (MINLP) problem. First-stage binary decisions cover infrastructure expansion, while second-stage variables optimize production, storage, and distribution under different scenarios. Renewable energy availability is modeled using scenario-based scaling factors, while demand incorporates sinusoidal seasonality with stochastic noise. Five representative scenarios over an eight-day horizon are simulated to evaluate system performance.

Case study results for a complex hydrogen network—comprising three production sites, two storage hubs, and two distribution centers—demonstrate the effectiveness of the framework. ProdA, with the lowest expansion cost ($10/kg), is the sole facility selected for capacity expansion under both expected-cost and worst-case strategies. ProdB and ProdC, with higher costs ($500/kg and $20/kg), are excluded. The expected-cost strategy achieves 12% lower average costs, while the worst-case strategy enhances resilience at a modest cost increase, highlighting the economic-resilience trade-off. Heatmaps of storage and production dynamics illustrate the system’s adaptability. Storage buffers supply in surplus periods and mitigates shortages during demand spikes. Production schedules shift based on scenario-specific conditions while ensuring feasibility. Demand fulfillment exceeds 90% across all simulations, confirming operational robustness. A cost vs. satisfaction plot further confirms that higher investment yields better reliability, validating the model’s resilience-focused approach. To address computational challenges, decomposition methods like Benders decomposition and column-and-constraint generation are used. Additionally, a hybrid multi-agent reinforcement learning (MARL) layer allows stakeholders to learn optimal policies through scenario-driven simulations, enhancing adaptive capabilities under uncertainty.

This study advances hydrogen supply chain resilience by combining proactive infrastructure planning with real-time operational flexibility. IPINNs ensure physical feasibility, while game theory facilitates coordinated, strategic decision-making among stakeholders. Policy implications include the potential for resilience credits, strategic storage incentives, and cooperative investment mechanisms to support market-wide adoption. The proposed framework provides a scalable decision-support tool for utility operators, policymakers, and investors seeking to build robust, low-carbon hydrogen ecosystems. In summary, the hybrid framework successfully harmonizes physics-informed learning, multi-stage game theory, and robust optimization to deliver cost-effective and resilient hydrogen supply chain strategies. By integrating long-term planning with dynamic operational agility, it paves the way for sustainable hydrogen infrastructure capable of adapting to the complexities of real-world energy systems.

References

[1] M.-K. Kazi, F. Eljack, M.M. El-Halwagi, M. Haouari, Green hydrogen for industrial sector decarbonization: Costs and impacts on hydrogen economy in qatar, Computers & Chemical Engineering 145 (2021) 107144.

[2] A. Arora, M.S. Zantye, M.M.F. Hasan, Sustainable hydrogen manufacturing via renewable-integrated intensified process for refueling stations, Applied Energy 311 (2022) 118667.

[3] V.M. Maestre, A. Ortiz, I. Ortiz, Challenges and prospects of renewable hydrogen-based strategies for full decarbonization of stationary power applications, Renewable and Sustainable Energy Reviews 152 (2021) 111628.

[4] A. Sánchez, Q. Zhang, M. Martín, P. Vega, Towards a new renewable power system using energy storage: An economic and social analysis, Energy Conversion and Management 252 (2022) 115056.

[5] T. Rathi, J.M. Pinto, Q. Zhang, Strategic low-carbon hydrogen supply chain planning under market price uncertainty, in: A.C. Kokossis, M.C. Georgiadis, E. Pistikopoulos (Eds.), Computer Aided Chemical Engineering, Elsevier2023, pp. 3357-3362.

[6] A.O. Bique, L.K.K. Maia, I.E. Grossmann, E. Zondervan, Design of hydrogen supply chains under demand uncertainty – a case study of passenger transport in Germany, Physical Sciences Reviews 8(6) (2023) 741-762.

[7] A.P. Barbosa-Póvoa, J.M. Pinto, Resilient supply chains – robustness and dynamics in the context of industrial gas supply chains, Computers & Chemical Engineering 179 (2023) 108435.