2025 AIChE Annual Meeting

(263d) Food Dye Microfluidic Mixing As a Micro-Scale Demonstration of Diffusion

Authors

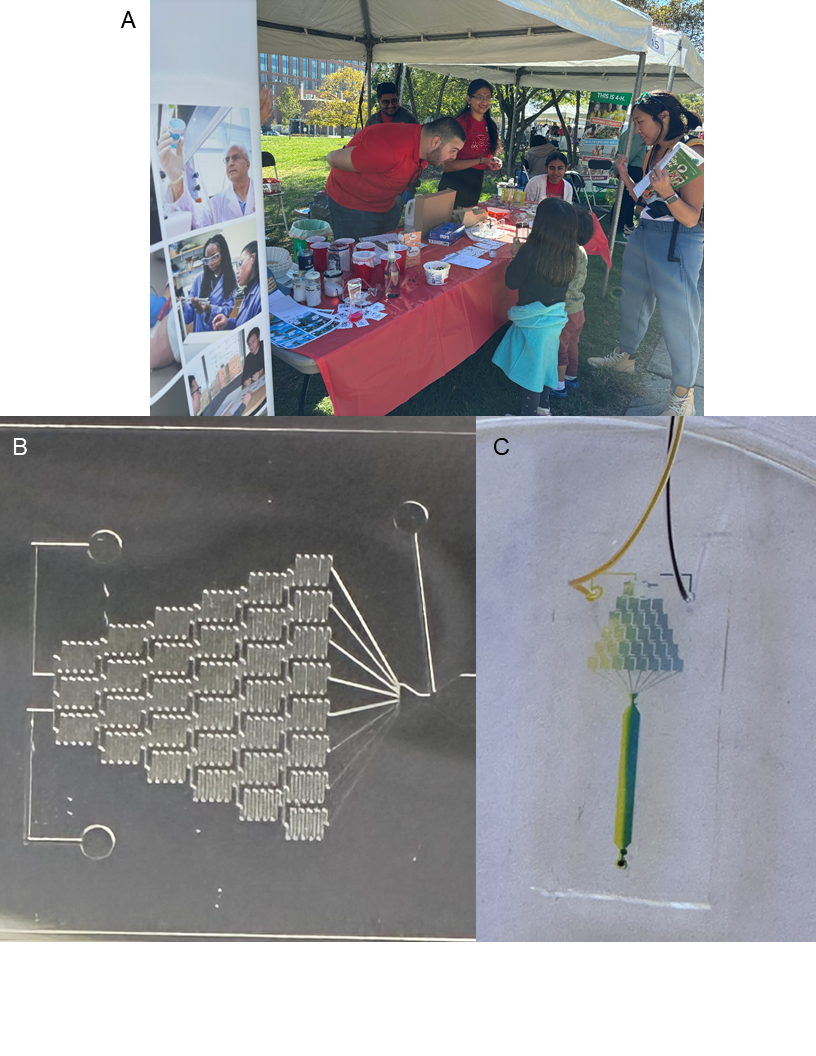

Methods: Photolithography is preformed to generate a mold for the microfluidic device. Briefly, SU-8 is spin coated onto a silicon wafer and a mask harboring the desired microfluidic device is UV exposed to imprint the device into the SU-8. While the uncured SU-8 is washed away, leaving just an imprint of the desired shape. PDMS is then poured into the mold and allowed to take the desired shape. This mold is nearly infinitely reusable and can be repurposed to generate many of the same demo devices, allowing this to be repurposed many times while just preforming the photolithography once. Once the PDMS has been set, it can be cut out and bonded onto a glass slide. This allows for the channels in the device to be water tight and allow for the demonstration to proceed.

Results: A mold for the microfluidic device was successfully created utilizing photolithography (Figure B). Which allows for the repeat generation of the demo device. This device was successfully bonded to a glass slide and two different colors of dyed water were flowed through either channel (Figure C). The colors were chosen with color theory in mind, so that they would produce a different color while mixed. The colors chosen in this example were yellow and blue, so that they would mix and make green. It can be seen that the colors laminarly flow through each of the microfluidic channels and in them they mix to produce different gradients of the mixed color. This is due to the design of the microfluidic channels to allow for each color to split and mix accordingly. The inlets to this device were two syringes filed with the concentrated dye solution. It was important for it to be concentrated for the dyes to be visualized inside the microfluidic channels. Since there are no harmful materials involved during the demo, the viewers can manipulate the pressures of the inlet syringes. This allows for them to visualize the different mixing potentials within the microfluidic channels, and since this is such a small scale there is not a large residence time for it to reach equilibrium again. Letting the viewers see in real time the effects of the different pressures on the resulting mixing gradients (Figure A). This creates a highly interactive and interesting demonstration of diffusion which captivates the attention of the viewers.

Implications: Through the generation of this microfluidic device and demonstration we allow for the microscale level of chemical engineering to be explore and discovered by the next generation of engineers. Allowing them to begin to think about both the largest and smallest scales of problems within this world. Especially since microfluidic mixing, flow and reacting is still much in its infancy compared to the large scale industry within chemical engineering. Therefore, this demonstration is the perfect introduction for the general population to begin to explore and question the differences from small to large scale which chemical engineers must question in their everyday life. Which allows for the next generation of thinkers to start to question how they can have such large scale impacts through their career and life choices.