2025 AIChE Annual Meeting

(40a) Exploring Pharmaceutical Powder Cohesion through the Warren Spring Cohesion Test

Authors

In a published study, a similar approach using a Warren Springs geometry on an air-bearing rotational rheometer was employed to assess cohesion in semi-crystalline and crystalline powders (2). The results observed that MCC PH101 exhibited the highest cohesion strength among test powders (corn, wheat, and potato starches) due to its high particle aspect ratio and crystallinity. Both studies highlight the Warren Spring cohesion test's effectiveness in directly measuring powder cohesion and its potential for faster assessments in the pharmaceutical and food industries.

In this study, the primary objective was to explore the application of the Warren Spring cohesion test to obtain insights into powder flowability, particularly in the context of pharmaceutical applications. A wide range of pharmaceutical powders were selected in terms of their flowability (Avicel® PH-101, Avicel® PH-105, Avicel® PH-200, Avicel® PH-301, Micronized Acetaminophen, Dense Powder Acetaminophen, Semi-Fine Acetaminophen, PEARLITOL® 25C, Pharmatose® 200M, C☆PharmGel® maize starch, Prosolv® SMCC 50LD, and Magnesium Stearate). A new methodology was investigated in this work to expand the applicability of the test beyond just characterization for cohesive powders, making it suitable for a broader range of materials, including free-flowing powders. Finally, a comparison was conducted between the results obtained from the Warren Spring cohesion test and those from an annular shear tester, the Brookfield powder flow tester (PFT).

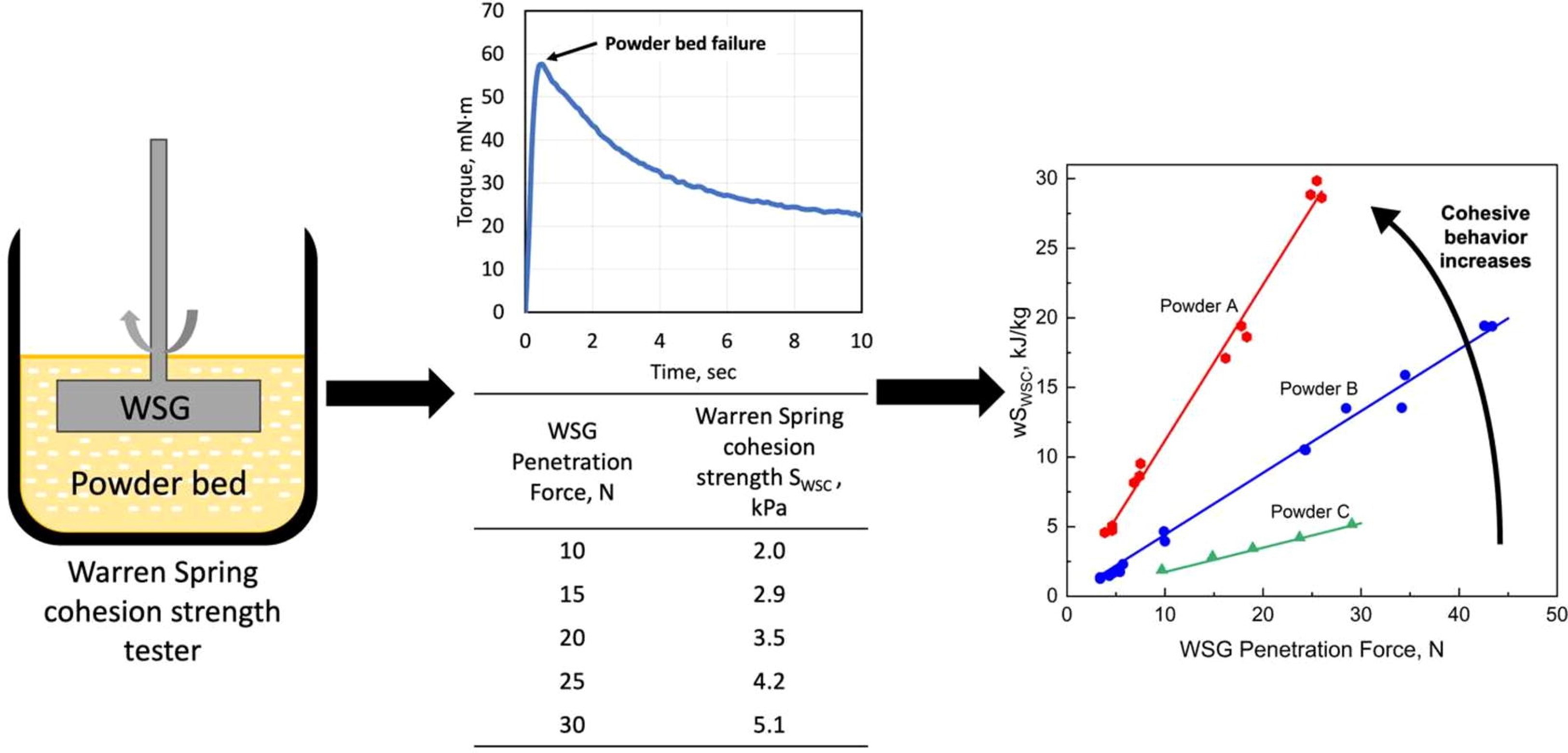

When exploring the behavior of two grades of MCC PH, A101 and 301, we employed a modified testing method that focused on controlling the penetration force applied by the WSG during its insertion into the powder bed, rather than the default method, which controlled penetration depth. Experiments were conducted at normal stresses of 0.25 and 1.00 kPa for A101 and 0.25 kPa for A301. To assess SWSC, maximum WSG penetration forces of 10, 15, 20, and 25 N were chosen for both powders. Once the WSG penetrated the powder bed until the specified forces were reached, rotational torque begins, and the SWSC is calculated. Despite the WSG not being fully immersed in the powder bed at 10 mm, consistent and reproducible data were obtained. This modified method was subsequently investigated using powders that had performed well with the default method, specifically A105 and SF-APAP, both of which exhibited an increase in SWSC with rising pre-compaction stresses.

A robust linear correlation between weighted Warren Spring cohesion strength and penetration force was established, with the slope of this relationship, mWSC, serving as a key metric for assessing powder cohesiveness. Lower slope values (0.17 mWSC, m/g: DP-APAP) indicate free-flowing powders, while higher values (1.12 mWSC, m/g: M-APAP) suggest cohesive behavior. This slope enables effective comparisons of cohesiveness across different materials. Additionally, this approach significantly reduced the experimental workload, requiring only a few data points to determine the slope, thus saving both time and resources.

The materials underwent characterization using a Brookfield PFT shear tester. The results showed a strong correlation between cohesion measurements from the Brookfield PFT and the Anton Parr Warren Spring tester. Although both methods demonstrated a good correlation, their sensitivity to detect differences in powder cohesion varied, suggesting that each method may be advantageous under specific conditions. For the PFT, the cohesion is dependent on the pre-consolidation stress applied; in the WSC test, it is not, but rather the penetration force. Thus, the comparison cannot be directly correlated regarding other powder properties, including differences in instrument methodologies. Specific powders analyzed, such as MgSt show a high slope value (0.72 mWSC, m/g) in the WSC test compared to the PFT (0.49 mPFT, m3/g). On the other hand, A105PH shows a low slope value (0.32 mWSC, m/g) in the WSC test compared to the PFT (0.68 mPFT, m3/g).

Overall, while the Warren Spring cohesion test is not intended to replace shear cell testing, it provides valuable insights into powder flow behavior and presents a complementary technique for assessing powder cohesiveness in pharmaceutical applications.

(1) Vyas, Z. D., Sen, A., Shetty, A., Callegari, G., Muzzio, F. J., & Razavi, S. M. (2025). Exploring pharmaceutical powder cohesion through the Warren Spring cohesion test. Advanced Powder Technology, 36(1), 104745.

(2) Jange, C. G., Taku, P., Peng, S., Dixon, M. P., Shetty, A., & Ambrose, R. K. (2020). Cohesivity assessment of semi-crystalline and crystalline powders using a Warren Springs cohesion tester. Powder Technology, 371, 96-105.