2025 AIChE Annual Meeting

(639c) Exploring Large Catalyst Composition Spaces Via Machine Learning

Authors

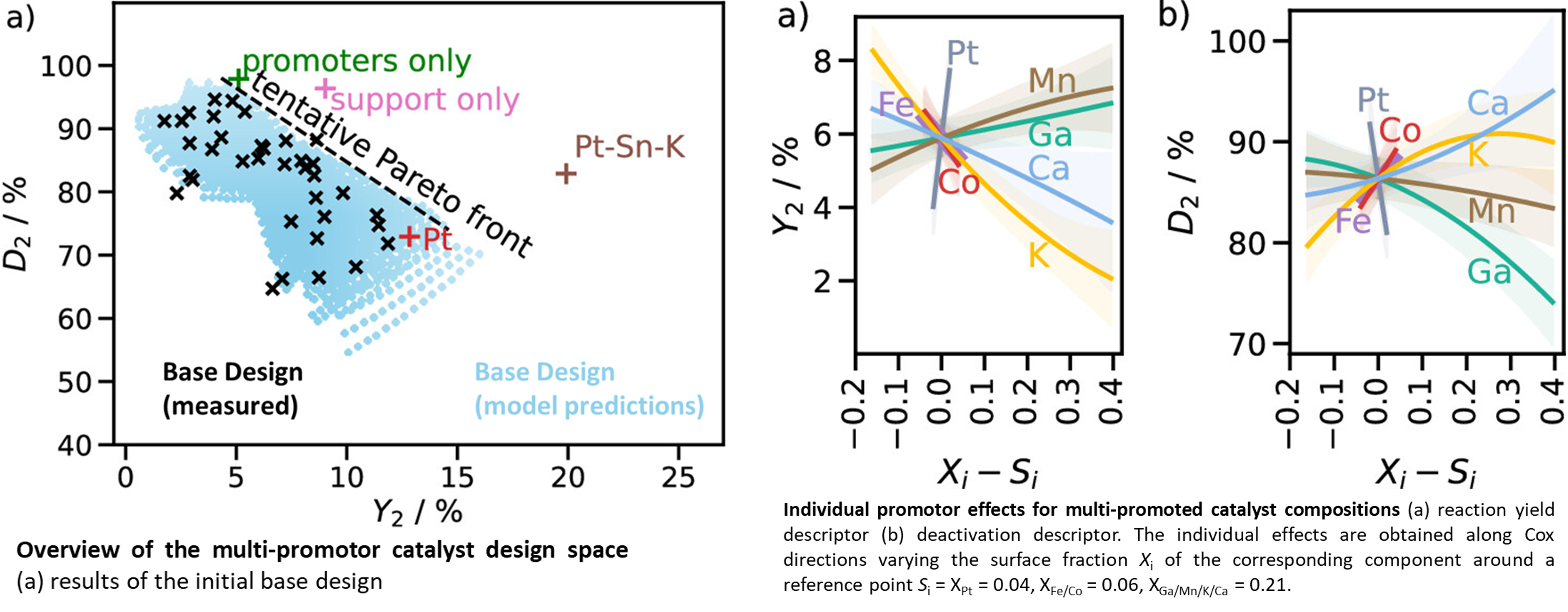

Our work showcases a multi-promoter study exploring a large catalyst composition space by varying seven elements simultaneously- in contradiction to single promotor studies. Promotors such as Fe, Co, Ga, Mn, K, and Ca are combined with Pt on θ-Al₂O₃ to create complex interfaces that involve Pt-promotor, support-promotor, and promotor-promotor interactions. Each catalyst is synthesized via incipient wetness impregnation using an automated syringe pump, ensuring a fast and reliable synthesis while following a defined mixture constraint.

The ML approach was applied to catalyst optimization for propane dehydrogenation. The active learning process starts with a base design covering 7265 catalyst predictions, from which only 35 are initially synthesized and tested in semi-automated setups. Subsequent iterations use the newly generated data to refine the primary algorithms, predicting 7265 new catalyst compositions.

Following the mixture constraint of the base design impeded the improvement of catalytic performance. A “human-in-the-loop” redefines the introductory settings, overcoming initial design restrictions and leading to an advanced adaptive design, laying the groundwork for “self-driving laboratories.” Extending our base design led to 19836 new predictions. Ultimately, we identified a catalyst that is competitive with the industrial reference.The identification of a competitive catalyst was achieved with less than 100 experiments, reflecting high efficiency in terms of required data points and time.

These results paved the way for investigations greater in complexity. Our current work covers a significantly higher-dimensional space, evaluating the effects of different support materials and increased number of promotors.