2025 AIChE Annual Meeting

(218d) Experimental and Numerical Study of the Mixing Performances and Oxygen Mass Transfer in a 200L Reactor

Authors

Computational Fluid Dynamics (CFD) has become the tool of choice for the numerical study of mixing processes inside stirred tanks [1]. Besides studying mixing performance, several works have investigated the oxygen mass transfer coefficient (kLa) in stirred reactors using different modeling approaches, e.g., [2, 3]. The overall oxygen transfer rate to the fluid depends on the gas bubble size distribution, fluid properties, local fluid energy dissipation rates, and local dissolved oxygen concentrations. There are two common approaches to building a multi-phase bioreactor model. The first approach combines a time-averaged solution for fluid flow with a continuous (Eulerian) description of the bubbles. In this method, bubbles are represented by a continuous number density across the fluid, with interactions handled via population balance models. The second approach considers bubbles individually as discrete spheres, assuming they are small relative to fluid computational cells.

In this work, we implement a mechanistic transport model in the CFD software ANSYS Fluent to predict mixing time and oxygen transfer rates within stirred-tank bioreactors. For the modeling of the gas phase, we apply the second approach, namely the Eulerian-Lagrangian specification, to describe the multi-phase system. For model validation, we use experimental data obtained from a 200L reactor. The reactor is equipped with two ZETA impellers, a ZETA mixing system at the bottom, four baffles, and a finger sparger installed below the bottom impeller.

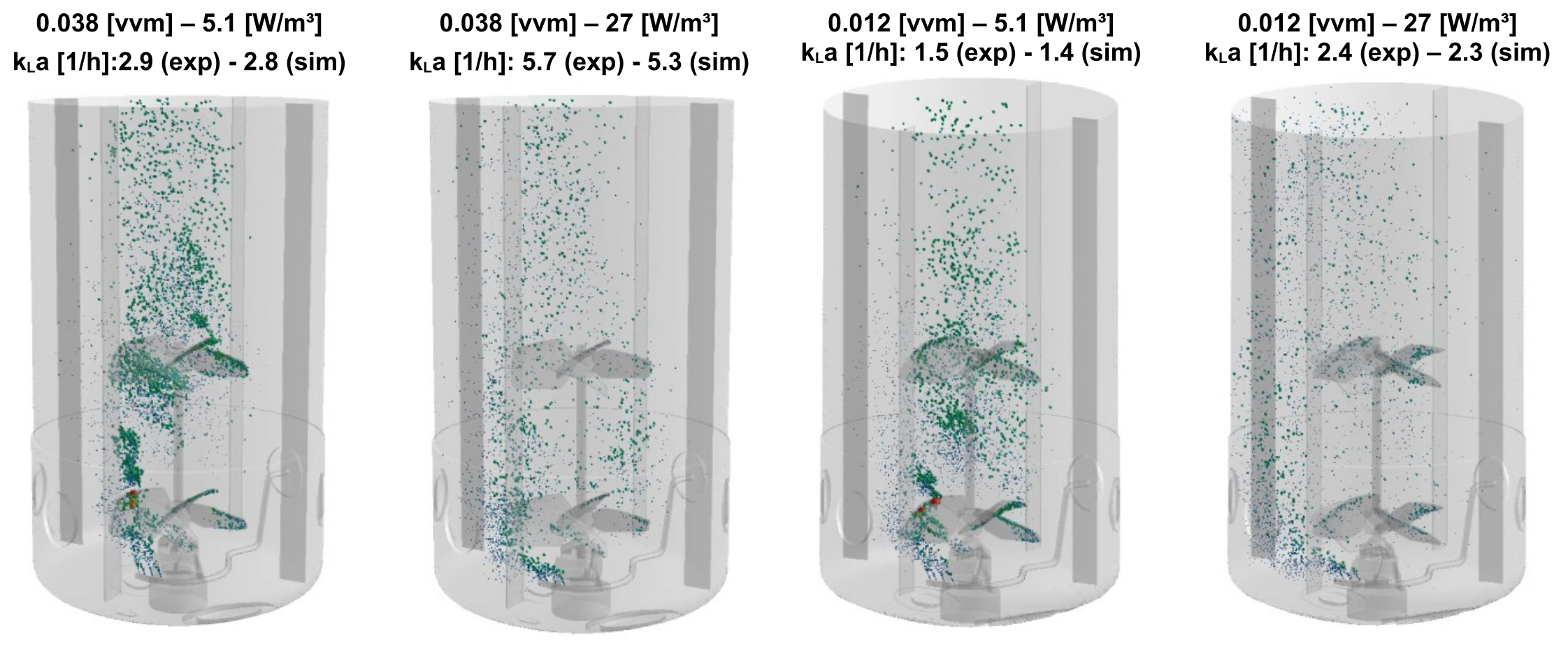

At the outset, we present the relevant conservation laws that govern fluid, bubble, and species transport within the tank. Bubble coalescence and break-up are modeled using pre-implemented models in ANSYS Fluent, while the oxygen mass transfer calculation is handled through an implementation using a user-defined function. The model validation began with the analysis of mixing performance, specifically through the evaluation of mixing time. Three different mixing speeds were studied and compared with experimental results. For the oxygen mass transfer study, two mixing speeds and two gas flow rates were considered. Instantaneous snapshots of the bubble distribution for the four studied conditions are shown in Figure 1.

The presented study identified key differences in mixing behavior in the 200L reactor across several mixing speeds. A good agreement between experimentally obtained mixing times and numerically calculated values confirms the model's accuracy. For the studied conditions including gassing of air, a good agreement between experimental and numerical data was also achieved. We present and analyze the differences in the flow regime and bubble distribution for the four studied conditions, which in the end explain the range of kLa values between 1.5 [1/h] and 2.9 [1/h]. Finally, an example of scaling up from the 200L reactor to a larger scale will be briefly discussed.

References

[1] Sharma C. et al., 2011. "Review of Computational fluid dynamics applications in biotechnology processes"; https://doi.org/10.1002/btpr.689.

[2] Amer M. et al., 2019. "Using CFD simulations and statistical analysis to correlate oxygen mass transfer coefficient to both geometrical parameters and operating conditions in a stirred-tank bioreactor"; https://doi.org/10.1002/btpr.2785.

[3] Thomas J. et al., 2021. "A mechanistic approach for predicting mass transfer in bioreactors"; https://doi.org/10.1016/j.ces.2021.116538.