2025 AIChE Annual Meeting

(95b) Evaluation of Ultrasound-Assisted Drill Cuttings Treatment

Authors

We have conducted a feasibility study and we evaluated if ultrasonication could serve as a sustainable alternative process to remove total petroleum hydrocarbons (TPH) from drill cuttings through controlled lab-scale tests. Hydrocarbons typically adhere strongly to cuttings due to van der Waals forces. Low-frequency ultrasonication can induce cavitation, providing the necessary energy to release oil from particle surfaces. This process also creates shear forces and increases flow rates, enhancing mass transfer and generating larger surface areas, which promote oil diffusion from the solid surface. Two types of batch ultrasonication treatments were conducted on two different types of cuttings: one involved sonicating the cuttings as-received, and the other involved sonicating the cuttings as a slurry. The OOC was quantified before and after treatment, and the effect of the treatment time, sonication power intensity, sonication treatment type, and the use of surfactants were explored.

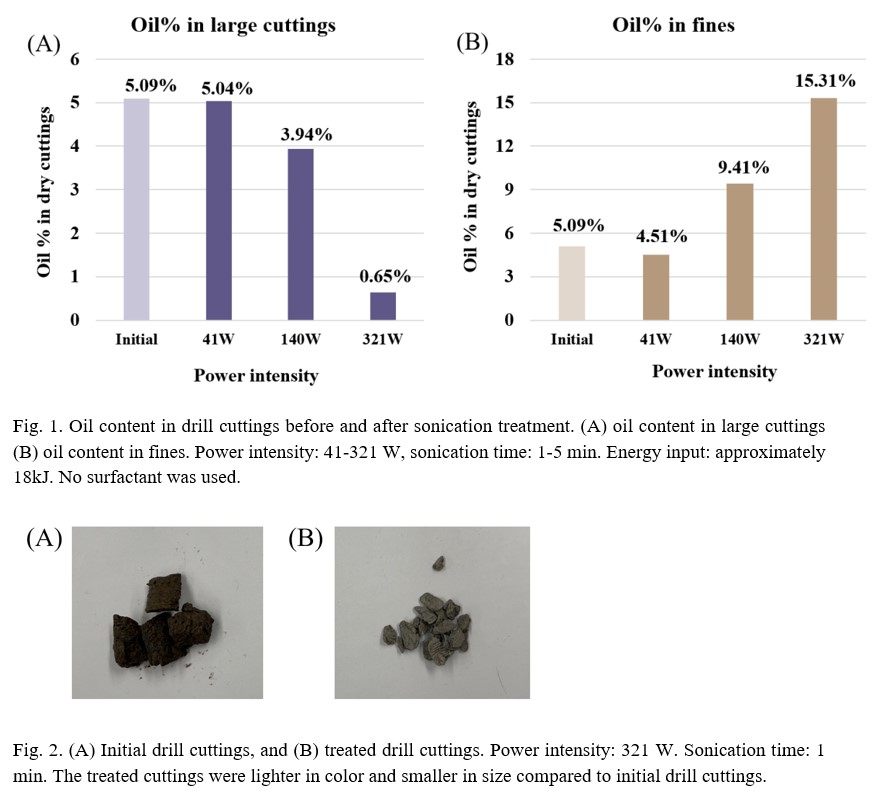

It was found that if cuttings were treated as-received, sonication treatment was effective in oil removal from large cuttings: with sonication power intensity of 321 W and treatment time of 1 min, oil content was reduced from 5.09% to 0.65% in large cuttings without the use of any chemicals and met the OSPAR standards for safe discharge. However, oil content of the fines generated during sonication generally increased relative to the oil content of the as-received cuttings. The addition of surfactant (sodium dodecyl sulfate) facilitated the cleaning process by bringing down the oil content of the large cuttings. A secondary sonication treatment of the residual fines did not effectively remove oil from fines even with the addition of surfactant. Additionally, if cuttings were treated as a slurry, sonication was not effective under any test conditions.

This study demonstrates that the ultrasound-assisted cleaning method could be feasible for certain size of cuttings. However, challenges remain in treating fine cuttings, clay samples, and slurrified materials, as well as in effectively removing oil to meet dischargeable limits. Further exploration is needed before the method could be considered for field application.

References

[1] Kirkness, A., and Garrick, D.: “Treatment of Nonaqueous-Fluid Contaminated Drill Cuttings-Raising Environmental and Safety Standard,” paper SPE 112727 presented at the SPE Drilling Conference, Orlando, Florida, USA (Marc 4-6, 2008).

[2] Metlon, HR., Smith, J. P., Mairs, H. L., Bernier, R. F., Garland, E., Glickman, A. H., Jones, F. V., Ray, J. P., Thomas, D., and Campell, J. A.: “Environmental Aspects of the Use and Disposal of Non Aqueous Drilling Fluids Associated with Offshore Oil & Gas Operations,” paper SPE 86696 presented at the SPE International Conference on Health, Safety, and Environment in Oil and Gas Exploration and Production, Calgary, Alberta, Canada (Mar 28-31, 2004).

[3] Huang, Z., Xu, Z., Quan, Y., Jia, H., Li, J., Li, Q., Chen, Z., and Pu. K.: “A Review of Treatment Methods of Oil-Based Drill Cuttings,” paper presented at IOP Conf. Ser.: Earth Environ. Sci. 170 022074 (2018).