2025 AIChE Annual Meeting

(123d) An Equation-Oriented Framework for Optimal Design of Amine-Based Carbon Capture Processes

Authors

Motivated by the above, this presentation describes a framework for design optimization of amine-based capture processes, as the most mature and accepted capture technology. Specifically, an equation-oriented set of models is described and used to formulate a design optimization problem aimed at minimizing capital and/or operating cost. The models are implemented in gPROMS Process® and are available open source to interested parties[1,2].

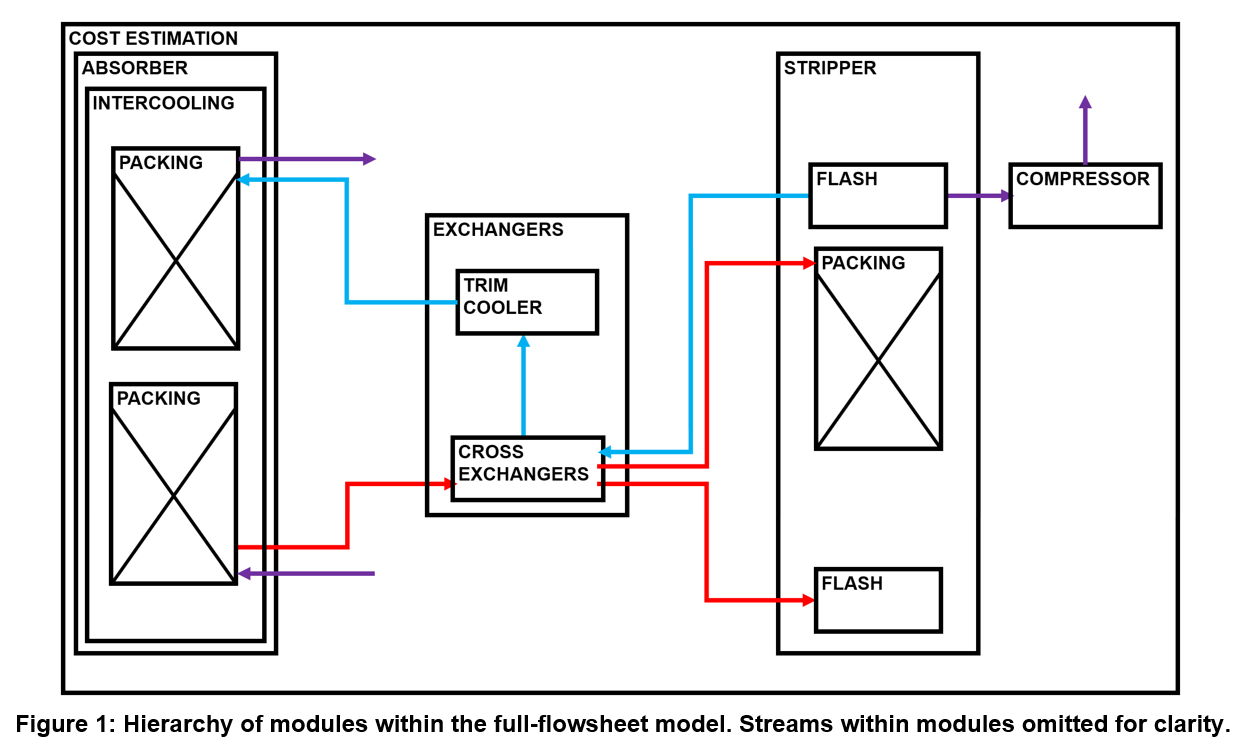

Figure 1 shows the model structure and main material streams. For the absorber and stripper, CO2 absorption and desorption are represented using a rate-based mass transfer model. The liquid-film mass transfer coefficient () is correlated from data generated by a model that involves detailed speciation in the solvent phase. Experimental measurements of the PZ-H2O-CO2 equilibrium are used to regress a thermodynamically consistent set of equations for the necessary thermodynamic quantities.

Publicly available front-end engineering design (FEED) studies for retrofitting commercial natural gas combined-cycle (NGCC) power plants with aqueous amine carbon capture were used to develop realistic capital cost estimates[3].

A design optimization case study for a natural gas-fired cogeneration unit (combined heat and power) is presented. Several cases are considered. As a baseline, a design optimized for typical NGCC conditions is used directly, with design variables like the intercooling configuration, rich solvent bypass ratios, and lean/rich solvent loadings held unchanged. This reflects a typical industry practice of using a standardized plant for each application. Subsequently, the design is optimized for the specific flue gas conditions of the plant. It is shown that the optimized design achieves substantial savings compared to the standardized plant.