2025 AIChE Annual Meeting

(441h) Enhancing Pharmaceutical Production with Scaled-up Laser-Driven Annular Photoreactors

Authors

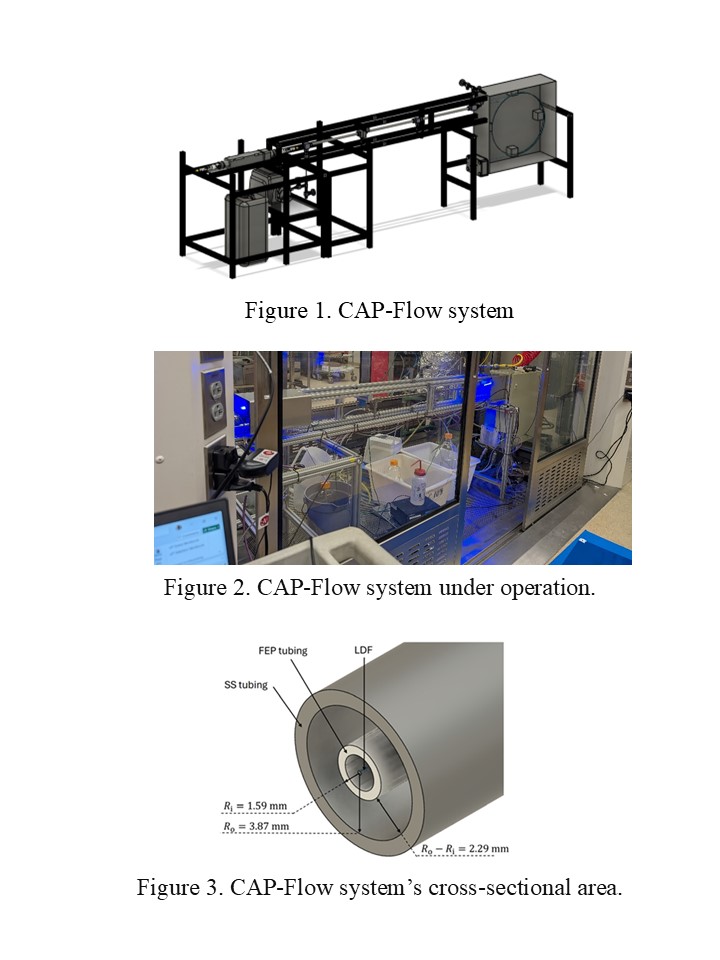

While LEDs have advanced photocatalysis, their use in photoreactors presents challenges such as heat generation, light dispersion, safety concerns, and emission variability, leaving room for further optimization. To address these challenges, we introduce the laser-driven Continuous Annular Photoreactor (CAP-Flow) system (see Figs. 1 and 2), which integrates radial light-diffusing fibers (LDF) with a laser diode via fiber optics. This design offers superior control, efficiency, and scalability for pharmaceutical photocatalysis. Compared to LEDs, laser technology provides highly monochromatic light, minimal beam divergence, and remote photon delivery—enhancing process control, heat management, and overall reactor safety.

The CAP-Flow system is modular and designed for continuous operation, utilizing standard fluidic components. The LDF is enclosed within transparent fluorinated ethylene propylene (FEP) tubing and housed inside a stainless-steel cylindrical structure, forming an annular reaction zone (see Fig. 3).

A previous study on the small-scale CAP-Flow system demonstrated its effectiveness using a 500 mW laser diode, actinometry, and a C–N cross-coupling photoreaction. This presentation will focus on the development and performance of the kg-scale CAP-Flow system, designed to assess the scalability of the lab-scale prototype. The reactor volume was increased sixteen-fold, and the system is capable of operating at laser powers up to 1,600 times higher than the small-scale version, utilizing a high-power 800 W blue laser and a specialized LDF. Experimental results demonstrate the system’s versatility and potential for large-scale pharmaceutical photocatalytic applications, offering a promising alternative to existing batch and flow technologies.