2025 AIChE Annual Meeting

(401p) Enhancing CO2 Permeability of PDMS Nanocomposite Membranes By Incorporating Mesoporous Silica Particles Toward Efficient Gas Separation

Authors

Keishi Suga, Osaka University

Hikaru Namigata, Tohoku University

Kanako Watanabe, Tohoku University

Tom A. J. Welling, Tohoku University

Daisuke Nagao, Tohoku University

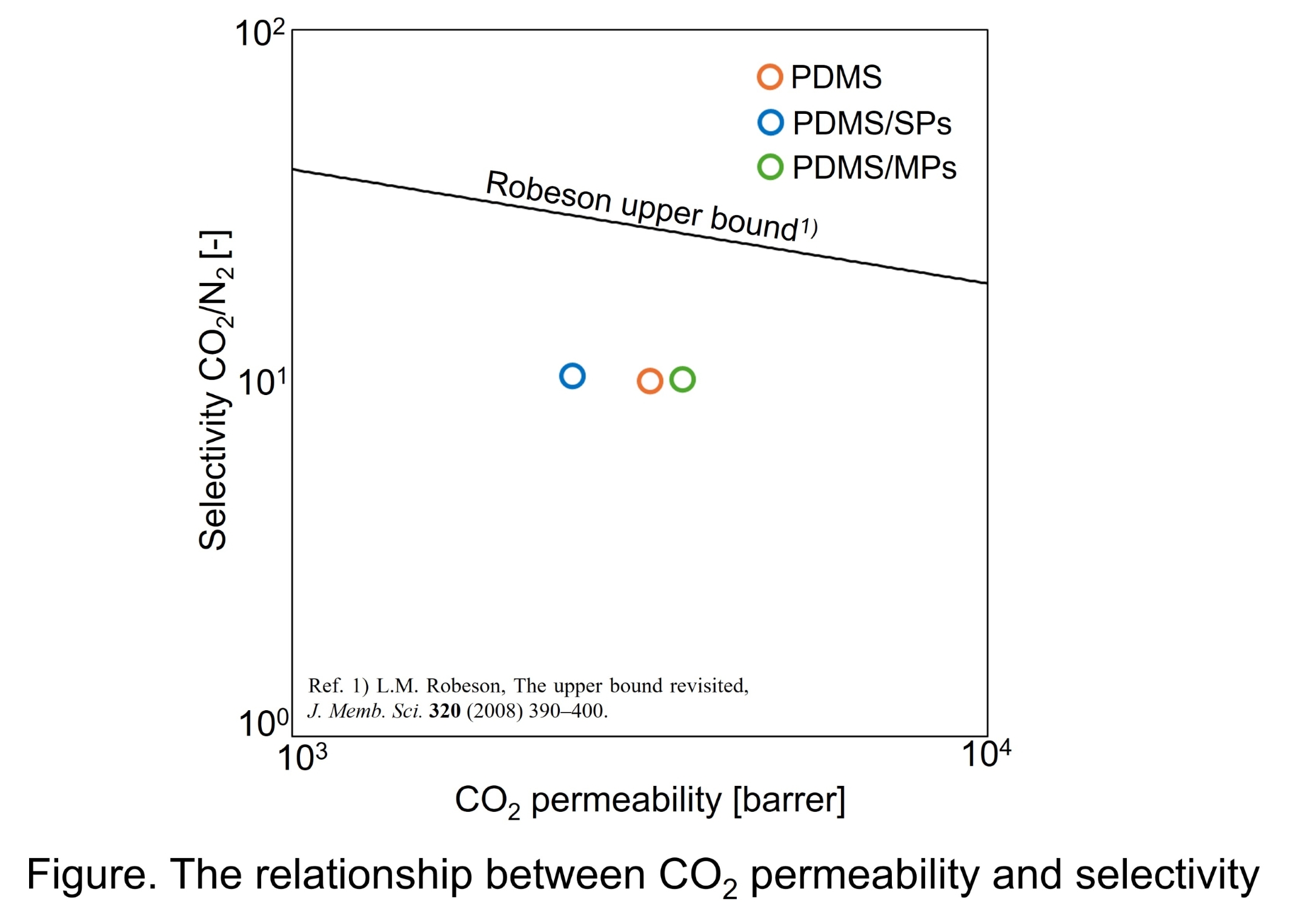

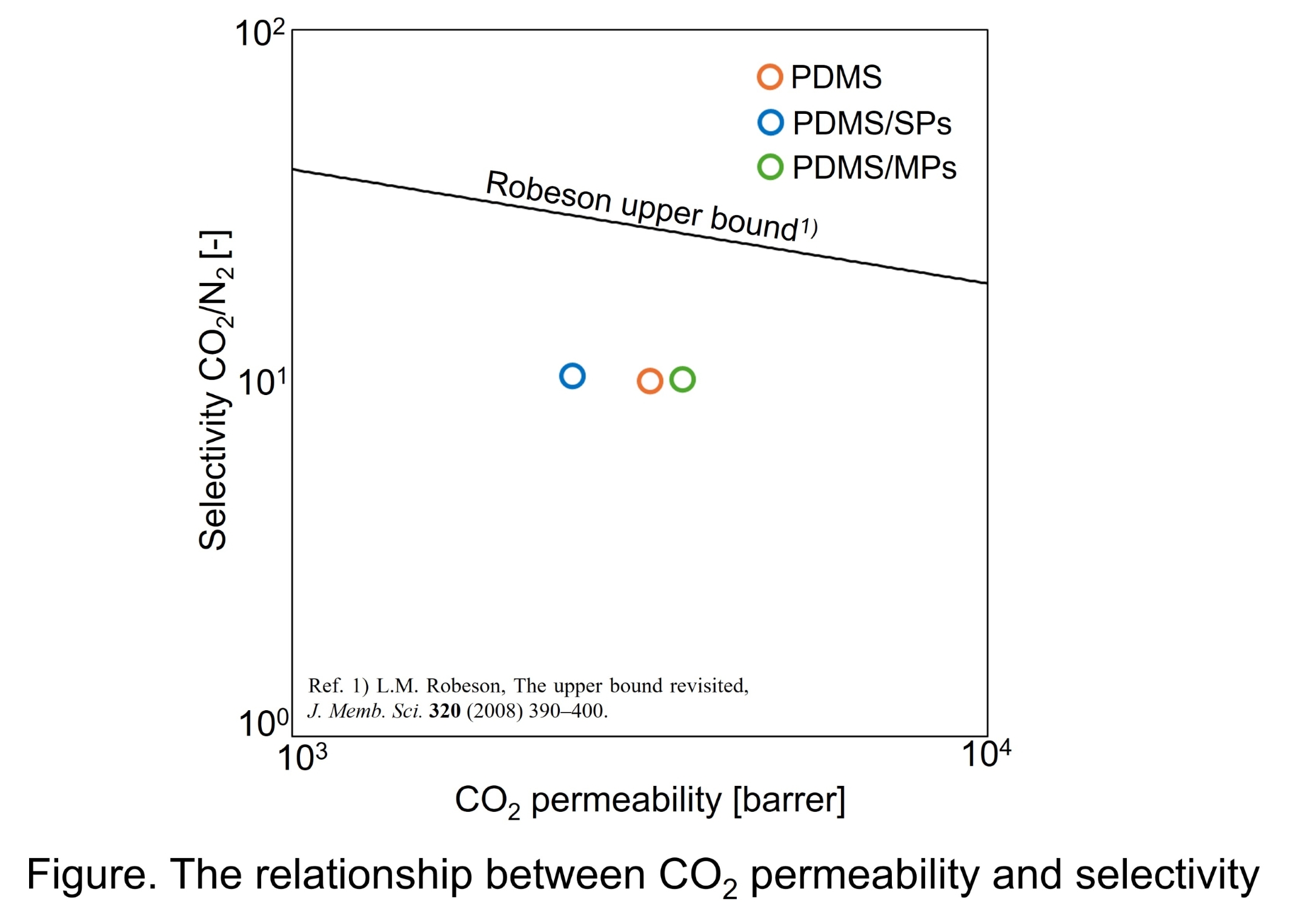

CO2 separation has attracted attention in various fields such as direct air capture and the production of energy resources (e.g., CO2 methanation). Gas separation membranes have been extensively studied as a promising route toward efficient CO2 separation and recovery, due to their ease of operation, energy efficiency, and environmental friendliness. Among gas separation membranes, mixed matrix membranes (MMMs), which combine the advantages of particulate fillers and polymer matrices, are promising materials. Polydimethylsiloxane (PDMS) has been widely studied as a matrix polymer for MMMs because of its flexibility and unique gas permeation properties, such as CO2/N2 selectivity. Mesoporous particles have attracted attention as fillers because they can enhance the gas permeability of MMMs in addition to improving their mechanical properties. However, the effects of mesoporous particles incorporated into PDMS membranes have not been studied in detail so far. In this study, the gas permeability and CO2 selectivity of the PDMS incorporating mesoporous silica particles (MPs) or Stöber silica particles (SPs) with a similar size were evaluated. The mechanical properties of membranes (PDMS, PDMS/MPs, or PDMS/SPs) were characterized through tensile testing, which revealed that MPs improved the strength of membranes more effectively than SPs. As shown in the figure, PDMS/MPs membranes exhibited enhanced CO2 permeability while CO2 selectivity was mostly maintained. Our investigations highlight the advantages of mesoporous silica particles as fillers, which can enhance both the mechanical property and gas permeability of MMMs.