2025 AIChE Annual Meeting

(643f) Energy and Process Network Flux Analysis: Screening and Synthesis of Sustainable Chemical Production Processes

Authors

EPNFA is an extension of our Process Network Flux Analysis (PNFA) [3] toward the simultaneous optimization of chemical processes and utility systems, including heat integration [4]. To this end, we develop a utility network model and link it with the process network model of PNFA and an additional model for in-process heat integration [5]. We embed the three models into a bi-objective nonlinear optimization problem, considering production cost as economic and global warming impact (GWI) as environmental objectives. We showcase the capabilities of our method in a case study on producing renewable chemicals and fuels based on a process network from previous work [6]. We solve the EPNFA optimization problem to identify optimal process pathways for four interesting chemicals and fuel candidates, i.e., ethanol, methanol, butanone, and 2-methylfuran (MF), using two different utility system superstructures, including conventional (USS1) and renewable energy carriers and conversion technologies (USS2) and compare the results to those from PNFA.

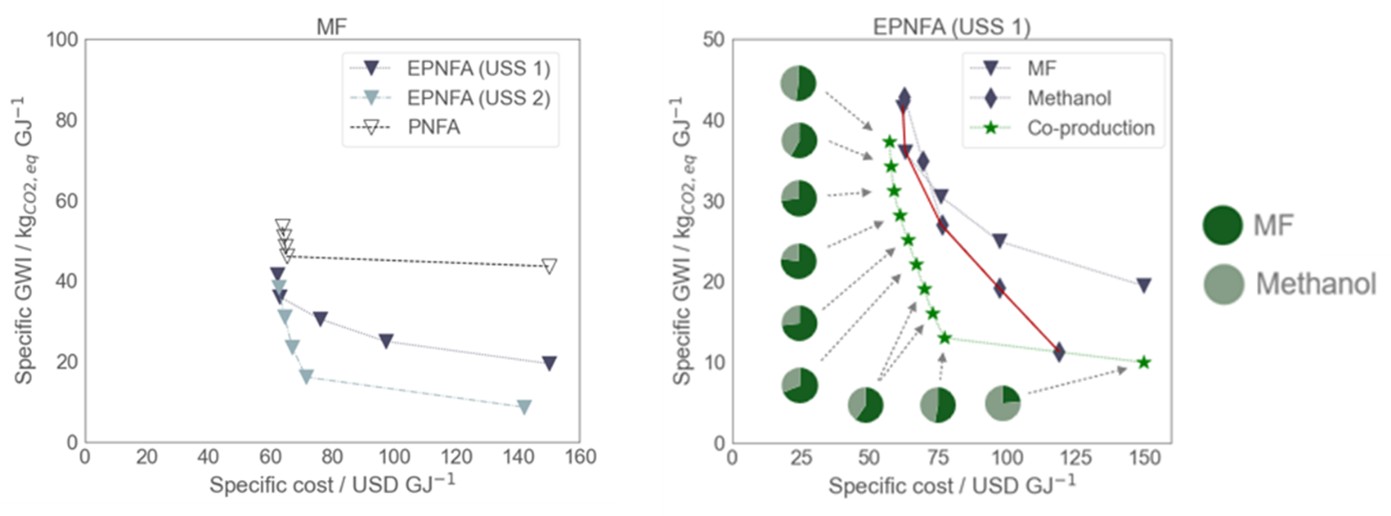

We show that energy-related synergies can significantly impact the performance criteria for sustainable production, particularly the production-related emissions, resulting from increased energy efficiency through in-process heat integration and combined heat and power utilization. Exemplarily for MF production (see Figure 1, left) these effects alone reduce emissions by more than 30%, even for a fossil-based energy supply, since energy demand is the primary driver of production-related emissions. The impact on production costs is less pronounced since raw material purchases and capital investment dominate over energy costs. When considering renewable energy supply options, we achieve even lower emissions, while integrated process concepts reduce the premiums for switching from fossil to renewable resources. In addition, the energy-related synergies can alter the ranking of products in screening and influence the optimal process pathway selection. For example, EPNFA shows preferences for processes at milder operating conditions and integrated separation processes in combination with combined heat and power generation, compared to PNFA. Beyond that, we identify benefits in co-producing multiple products, e.g., MF and methanol, over single-product facilities through integrated energy systems on a global fleet level (see Figure 1, right). We further demonstrate that with pathway screening methods focusing on the chemical process alone, these benefits might go unrecognized, underlining the importance of holistic design approaches in the early stages of process development.

References

[1] Pham, V.; El-Halwagi, M. (2012) Process synthesis and optimization of biorefinery configurations. AIChE J. 58, 1212–1221.

[2] Kim, J.; Sen, S. M.; Maravelias, C. T. (2013) An optimization-based assessment framework for biomass-to-fuel conversion strategies. Energy Environ. Sci. 6, 1093–1104.

[3] Ulonska, K.; Skiborowski, M.; Mitsos, A.; Viell, J. (2016) Early-stage evaluation of biorefinery pro-cessing pathways using process network flux analysis. AIChE J. 62, 3096–3108.

[4] Panofen, M.; Lang, L.; Viell, J.; Dahmen, M.; Mitsos, A. (2025) Energy and Process Network Flux Analysis: Optimization-Based Assessment of Sustainable Chemical Production Pathways. Ind. Eng. Chem. Res. DOI: 10.1021/acs.iecr.4c04896

[5] Papoulias, S. A.; Grossmann, I. E. (1983) A structural optimization approach in process synthesis-II. Heat recovery networks. Comput. Chem. Eng. 7, 707–721.

[6] König, A.; Siska, M.; Schweidtmann, A. M.; Rittig, J. G.; Viell, J.; Mitsos, A.; Dahmen, M. (2021) Designing production-optimal alternative fuels for conventional, flexible-fuel, and ultra-high efficiency engines. Chem. Eng. Sci. 237, 116562.

Figure 1: Comparison of Pareto fronts resulting from PNFA and EPNFA using two utility system superstructures, exemplarily shown for 2-methylfuran (MF) production (left). Results of MF/methanol co-production using EPNFA with USS1 in comparison to the single-product results (right). The pie charts illustrate the shares of MF and methanol of the total production capacity in co-production in GJ GJ−1, based on the lower heating value. The solid red line illustrates the Pareto front for combined single-product processes on a fleet level.