2025 AIChE Annual Meeting

(95g) Energy and Nanocarbons Production from Biomass: A Kg-Lab Scale Process Combining Autothermal Pyrolysis and Pyroproducts Dry Reforming

Authors

In this project a bubbling fluidized bed autothermal technological platform for pyroconverting biospheric carbon materials into a variety of vectors has been developed at kg-lab scale and produced the first proofs for its scalability. The innovation resides in the structure of the lower section of the bed, which functions as an exothermic oxidation reactor for recycled pyrogas, producing the thermal energy required for the endothermic pyroconversion that takes place in the upper part of the reactor. The design of the bubbling fluidized bed (FB) is well known, but it is strongly influenced by numerous parameters and variables. This means that, while theoretical design protocol is common knowledge, successful FB design must consider a large number of case-specific items. The aim of this project is to convert biospheric carbon materials into nanocarbons by combining bubbling fluidized bed autothermal pyrolyzer with a novel hybrid bubbling-mobile catalytic dry reformer.

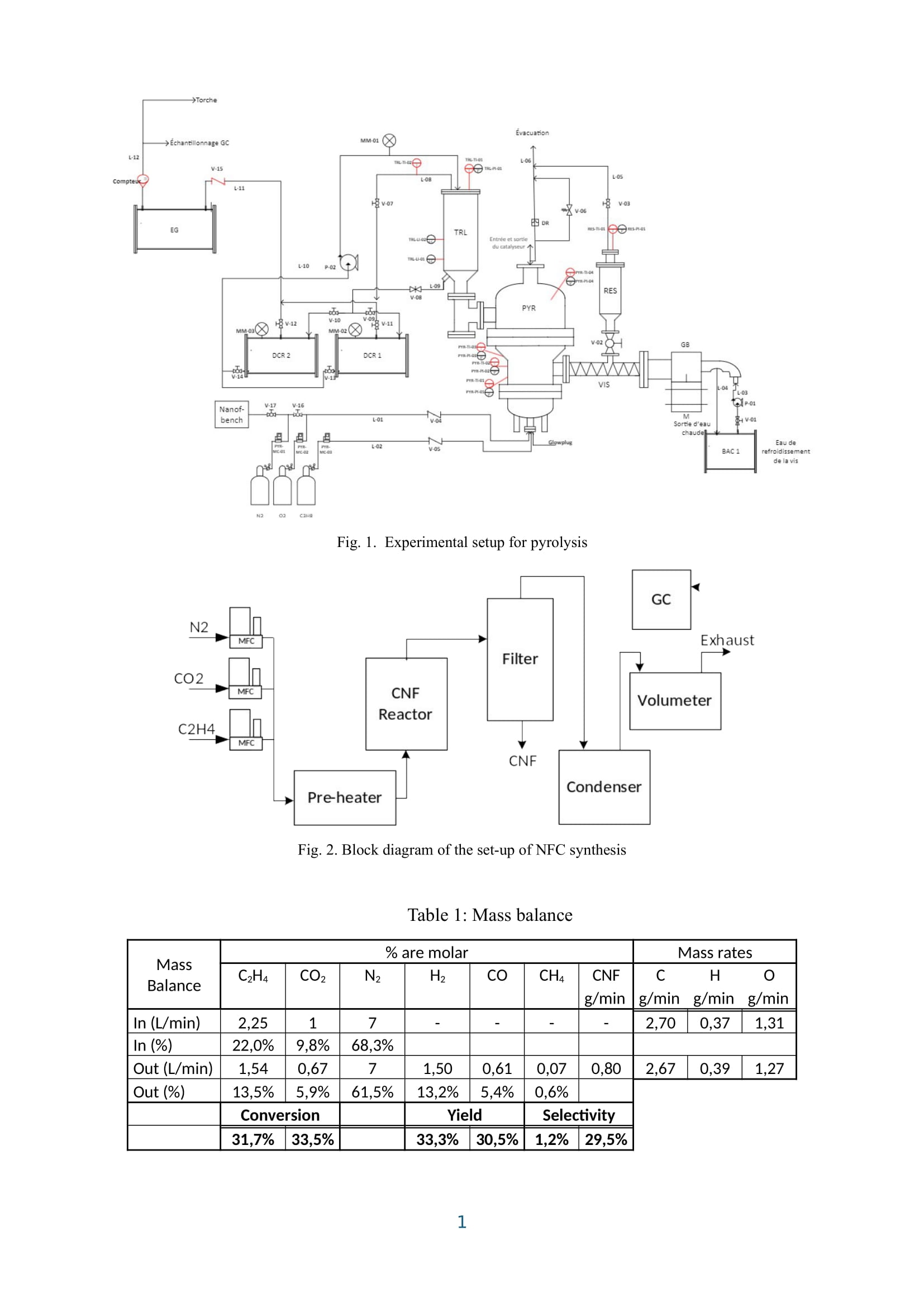

The initial step involves the pyroconversion of raw materials in the fluidized bed autothermal pyrolyzer. The raw materials used are the residual plastics (high-density polyethylene scrap) and lignocellulosic biomass (switchgrass biomass pellets). The experimental facility used for pyrolysis (PYR in Fig. 1) is designed in concrete and is thermally insulated with a reaction chamber of 5.12” internal diameter and 20.50” height. The bed, consisting of 1 kg of alumina oxide sand (with an average particle size of 250 μm), is maintained in fluidization by combustion gases fed through the distributor plate. In all experiments, a raw material mass flow rate of approximately 3 kg/h is fed in the reactor using a screw conveyor system.

The reactor is heated by propane combustion. When the operating temperature is reached, the raw material is introduced into the reactor. Simultaneously, the flow rates of the propane and air are carefully regulated to maintain stoichiometric combustion, providing the heat required for the process. The pyrolysis gases are carried to the reactor outlet. The pyrolysis gases pass through a cooling tower (TRL in fig.1) equipped with a water spray system. Then, the liquid fraction is condensed within the tower. The non-condensable gases are subsequently directed to a flare. The products are sampled and analysed.

The second step concerns the dry (CO2) reforming of the 1st step products to produce carbon nanofilaments (CNF) in a hybrid fluidized-mobile bed reactor (figure 2). C2H4 is used at this development stage to simulate the pyrolysis products. At the time of the conference there will be data with the utilization of pyroliquids as reactants. The reactor is heated under nitrogen and a protocol for the activation of the Fe-based catalyst is applied. The temperature of reaction is set at 550°C with a pressure around 5psig. The reactants are added (C2H4 at 2.25L/min STP and CO2 at 1L/min STP) and the nitrogen is adjusted to maintain the fluidization (7L/min STP). All fed gases flows are mass flow controlled. The exhaust gases are dried in a condenser and a volumeter totalizer allows its measurement. The composition is determined using a gas chromatograph Scion 456. The CNF are recovered from the filters and from the accumulation in the reactor. One experiment is usually done on several days since the heating of the reactor takes around 3h.

1. Pyrolysis results: The commissioning of the setup has been done using real waste plastics. So, the results presented in this abstract come from the pyrolysis of scrap plastics. Runs at 400°C and 550°C pyrolysis temperature levels are presented. During the EUBCE 2025, we will have similar results from biomass coming from fast growing crops used in soil decontamination and residual wood chips.

1.1. For the 400°C test the yields are:

- 3,2 % solids

- 27,5% gases and

- 69,3% pyroliquids

1.2. For the 550°C test the yields are:

- 0,2% solids

- 44,3% gases and

- 55,4% pyroliquids

The increase in temperature increased the gas/liquids mass ratio. GC-MS analysis of the pyroliquids showed that the oils obtained at 400°C are predominantly composed of oxygenates and long-chain hydrocarbons with fewer aromatics, whereas the oils obtained at 550°C are virtually free of oxygenates and are predominantly composed of aromatics. The gases obtained at 550°C were richer in methane, ethylene and propylene and less rich in hydrogen and carbon dioxide.

2. Dry reforming results: The conversion of C2H4 and CO2 are in average over time 32% and 34% respectively. These are not optimized results and the following steps target optimization to reach close to equilibrium yields. The Fe-based catalyst is essentially participating to the reaction through the formation of carbides which catalyze the production of CNF. Thus, this cheap catalyst is consumed during the reaction and, at real continuous operation scale, it must be continuously fed along with the reactants. There is a reduction of the conversion over time that could be related to the accumulation of the CNF which would reduce the access to the catalyst. At real industrial scale this carbon material would be skimmed off the catalyst particles and entrained along with the gas exiting the reactor as is the case for a major part of them even at this kg-lab scale. The CNF selectivity is 29.5% with a production of 0.8g/min. The total amount of CNF recovered from the reactor and filter is 1+kg over a 24h of time-on-stream. The mass balance is presented in table 1. In comparison, the same conditions in fixed bed reactor, give a conversion close to 100%; this is even the case with an addition of up to 75% nitrogen to the stream, which reduce the residence time and the concentration of the reactants. This indicates that the residence time that is too short in the fluidized bed and that the production is rather kinetically driven.