2025 AIChE Annual Meeting

(45e) Electrothermal Surface-Heated Membrane Distillation Using CNT-Coated Membranes for High-Efficiency Desalination of Hypersaline Water

More than a billion people worldwide lack reliable access to safe drinking water, emphasizing the critical need for sustainable water purification technologies. Desalination of seawater and other non-potable sources offers a viable solution, but the high energy demand, accounting for nearly half the operational cost of traditional desalination systems, remains a significant barrier. Among emerging desalination technologies, membrane distillation (MD) a thermal-driven membrane-based separation process, presents distinct advantages due to its capability to treat highly saline water at relatively low temperatures and pressures. However, its widespread application is hindered by the need to heat large volumes of feedwater, leading to low thermal efficiency and high energy consumption, and by limited water flux due to low vapor pressure gradients and membrane transport resistance.

Methodology

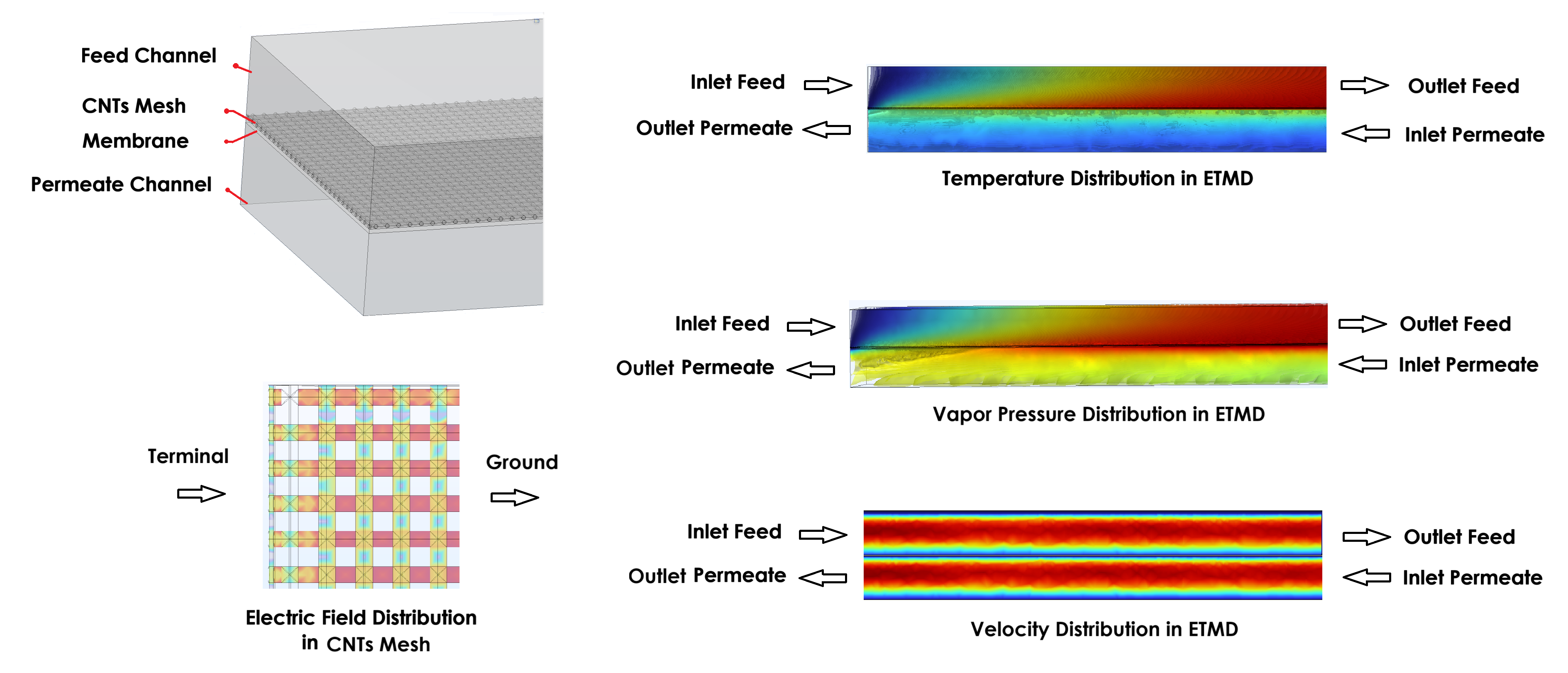

To address these challenges, we study surface-heated membrane distillation approach using carbon nanotube (CNT) coating as a scalable electrothermal heating layer directly applied to the membrane surface. This electrothermal membrane distillation (ETMD) system utilizes localized Joule heating to deliver heat precisely at the membrane-liquid interface, thereby minimizing heat loss and temperature polarization. The result is a significantly enhanced vapor pressure gradient and driving force for mass transfer, leading to higher water flux and energy efficiency.

In essence, the CNT coating acts as a uniform, highly conductive Joule heater with excellent corrosive resistance and thermal stability. Compared to conventional metal heating elements, CNTs provide faster heating response, lower thermal mass, and superior chemical durability, especially under the harsh conditions encountered in hypersaline desalination. The system is powered by a standard household-frequency alternating current (AC) source, enabling practical integration into existing infrastructure.

Results

Our simulation results demonstrate that the CNT-coated membrane can achieve surface temperatures of approximately 60 °C. At a power input of 30 kW m⁻², the system produces water fluxes exceeding 20 L m⁻² h⁻¹, with salt rejection consistently above 99.5%. These performance metrics represent a significant improvement over conventional membrane distillation (MD) - which typically suffers from low energy efficiency (< 5%) [1], as well as photothermal MD systems - which often exhibit limited water flux (<1.5 kg m⁻² h⁻¹) and poor long-term stability [2]. Notably, the overall energy efficiency of the system increased from less than 5% [1] in traditional MD to over 50% with CNT-based electrothermal heating.

Conclusion

This work demonstrates that directly integrating CNT-based heaters onto commercial membranes offers a scalable, energy-efficient, and high-performance solution for treating hypersaline brines. The system’s ability to deliver high water flux, excellent salt rejection, and sustained operation under high power intensities marks a significant advancement in membrane-based desalination. This solution holds strong potential for addressing the global water crisis through sustainable and cost-effective purification technologies.

Key Words: Electrothermal membrane distillation–based desalination, energy efficiency, nanotechnology

References

[1] Christie, Kofi SS, Thomas Horseman, and Shihong Lin. "Energy efficiency of membrane distillation: Simplified analysis, heat recovery, and the use of waste-heat." Environment international 138 (2020): 105588.

[2] Zhang, Yan, et al. "Multi-scale pore structured porous carbon nanofiber with light-limited domains for highly efficient photothermal membrane distillation." Separation and Purification Technology 356 (2025): 129984.