2025 AIChE Annual Meeting

(401d) Electrosprayed Amphiphilic Polyelectrolyte Complex Membranes for Water Treatment

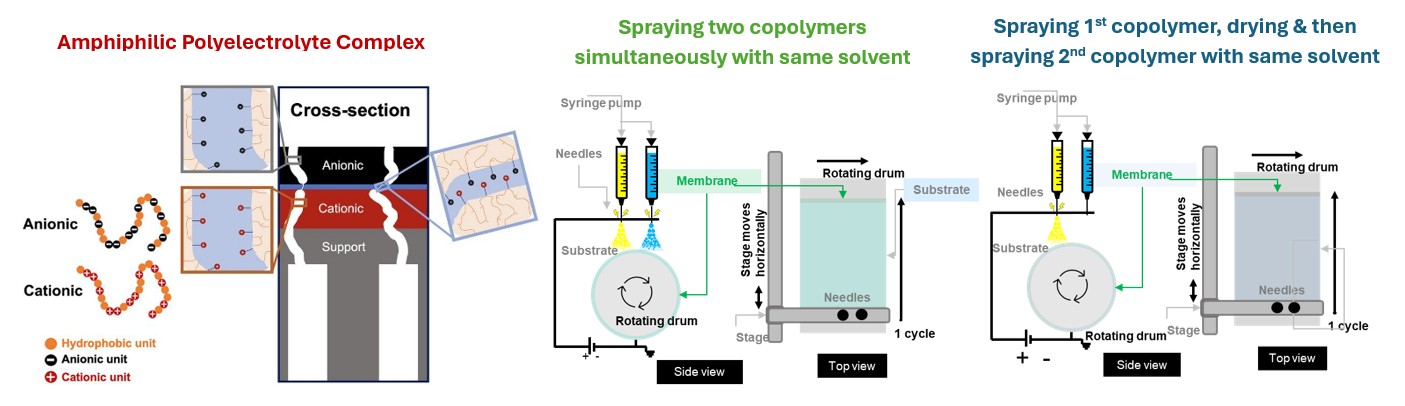

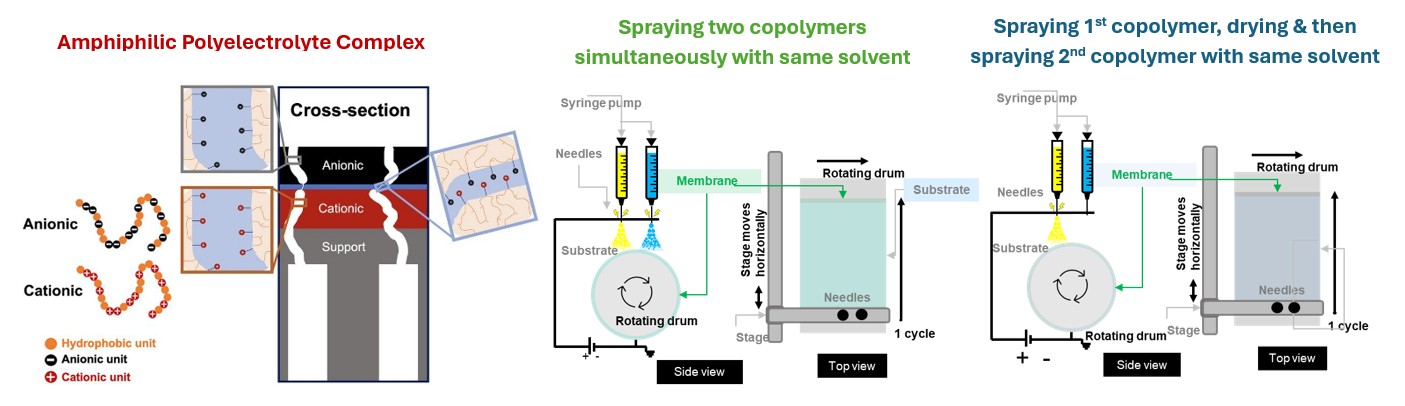

“Clean brine”, defined as saline water free of fouling contaminants, is crucial for effective and sustainable desalination. In reverse osmosis (RO) systems, the presence of contaminants in feedwater leads to membrane fouling, scaling and reduced recovery rates, causing increased operational costs and limited system performance. Clean brine allows RO systems to achieve higher recovery rates (>95%) by minimizing fouling and scaling risks. Despite advances in membrane materials, current pretreatment processes are capital-intensive, unadaptable to small systems and inefficient at removing organic materials of small molecular weight that can cause fouling in membranes. In this study, we have created the first nanofiltration (NF) membranes for universal pretreatment of saline waters for RO treatment systems. These membranes can treat any feed water to produce clean saline water for treatment. To achieve this, we have combined a novel material family, amphiphilic polyelectrolyte complexes (APECs), with an evolving manufacturing technique, electrospray printing (ESP), to develop start-of-the-art nanofiltration membranes for universal RO pretreatment. Electrospray 3D deposition uses an electric field established between the spray tip and the deposition surface. Charged spray droplets undergo coulombic fission along their trajectory, resulting in the generation of a finely dispersed spray-mist capable of forming membranes with thicknesses in the order of nanometers. This endows ESP with the ability to produce multi-layered, yet remarkably thin (tens of nanometers per layer or less), defect-free membranes. The use of numerous yet exceedingly thin bilayers can prevent defects while creating NF membranes with higher permeance than their commercial counterparts. ESP offers flexibility in membrane fabrication by enabling the use of different solvents and monomer structures for sequential sprays, allowing precise control over the composition and architecture of each layer. This technique permits thickness adjustability for each scan and simultaneous deposition of two or more copolymers, promoting enhanced self-assembly that cannot be achieved through conventional methods. Our membranes have shown pure water permeance up to 30-50 LMH/bar with MgSO4 rejection up to 40% and Vitamin B12 rejection up to 60%. ESP can operate with extremely low polymer concentrations (0.05 wt./wt.%), minimizing material usage while maintaining uniformity. Hence, electrospray is a flexible, scalable and efficient tool for advanced membrane manufacturing.