2025 AIChE Annual Meeting

(186j) Efficient and Sustainable Processing of CNT-Polyolefin Composites

Authors

These composites are typically synthesized via in-situ polymerization, solution blending or melt blending. While polymerization methods generally provide good properties and CNT alignment, this process requires tailored chemistries to synthesize composites which can be an expensive process. Therefore, methods for solution and melt-blending are being developed to provide a lower cost method. Solution blending allows for better control of CNT dispersion and alignment; however, difficulties arise in finding solvent compatibility and evaporation as many of the solvents needed are highly toxic. Alternatively, melt-blending does not require any solvent use but due to the high shear environments degradation of the polymer chains can occur and less control is had over the dispersion and alignment of fibers. Therefore, we propose a new method which combines the principles of melt and solution blending to address these shortcomings.

Our process utilizes insights gained from both of these processes to enable a low-carbon method for CNT-polymer composite synthesis. By using a lower shear environment than melt blending we are able to preserve molecular integrity of the polymer chains and limit degradation. Instead of dissolving the polymers and CNT in respective solvents and combining them, as done in solution blending, we can exploit the solubility differences between the two components and enable CNT dispersion. Hydrothermal water will swell the polymer matrix and enable chain relaxation allowing for additive incorporation. Then, as CNTs are insoluble in water, this change in chain relaxation makes it more energy favorable for CNTs to be incorporated into the polymer. Using a moderate stirring rate will also enable good dispersion of CNTs within the expanded polymer melt.

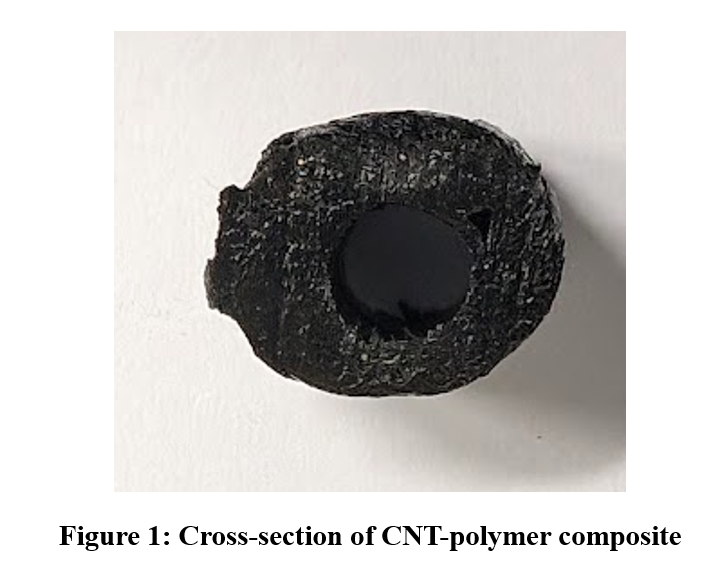

As seen in Figure 1, we can use this method to achieve a uniform dispersion of CNT throughout the polymer. This presentation will cover our process development and experimental results of composites synthesized with various loadings of single-walled and multi-walled CNTs.