2025 AIChE Annual Meeting

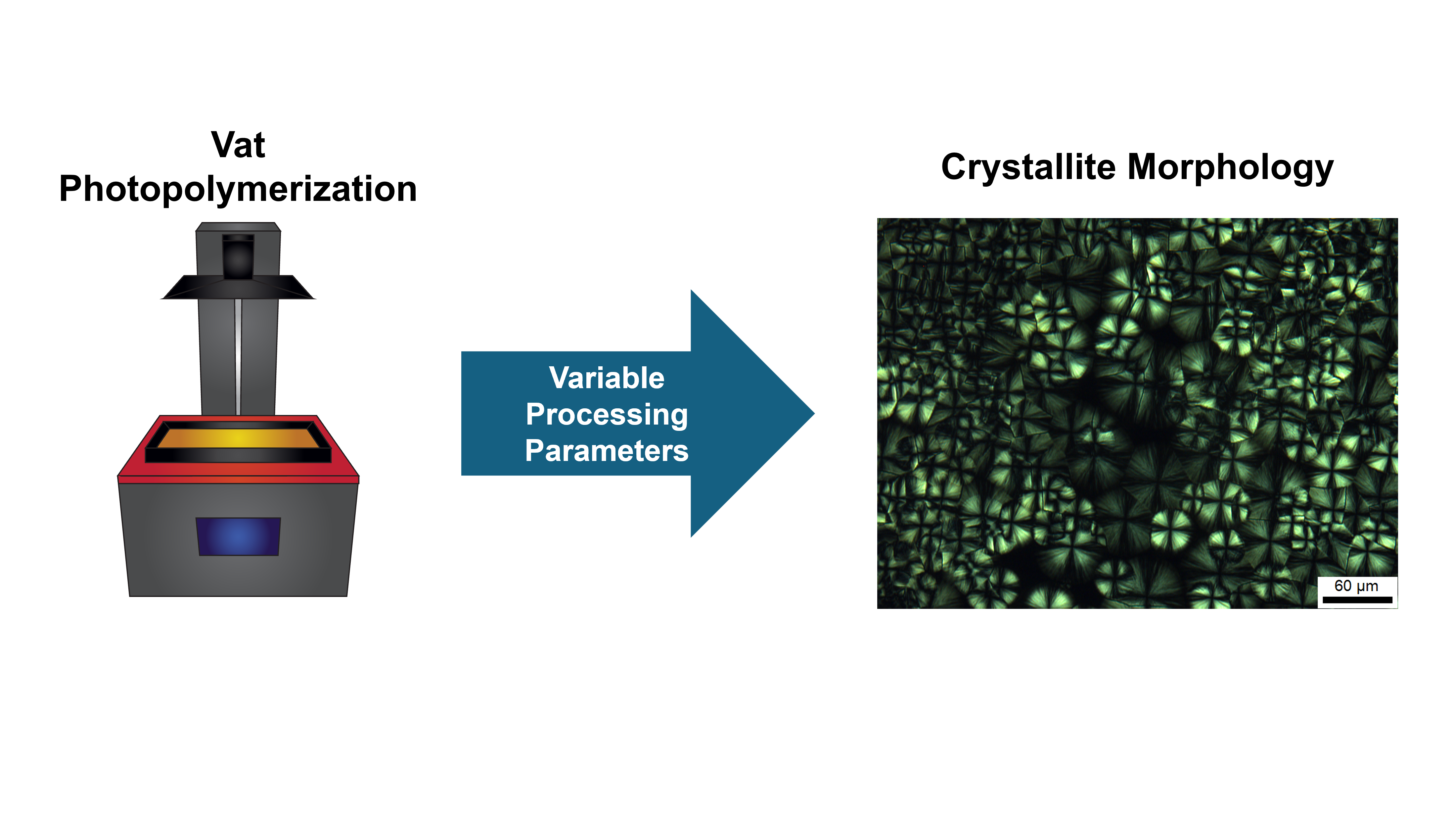

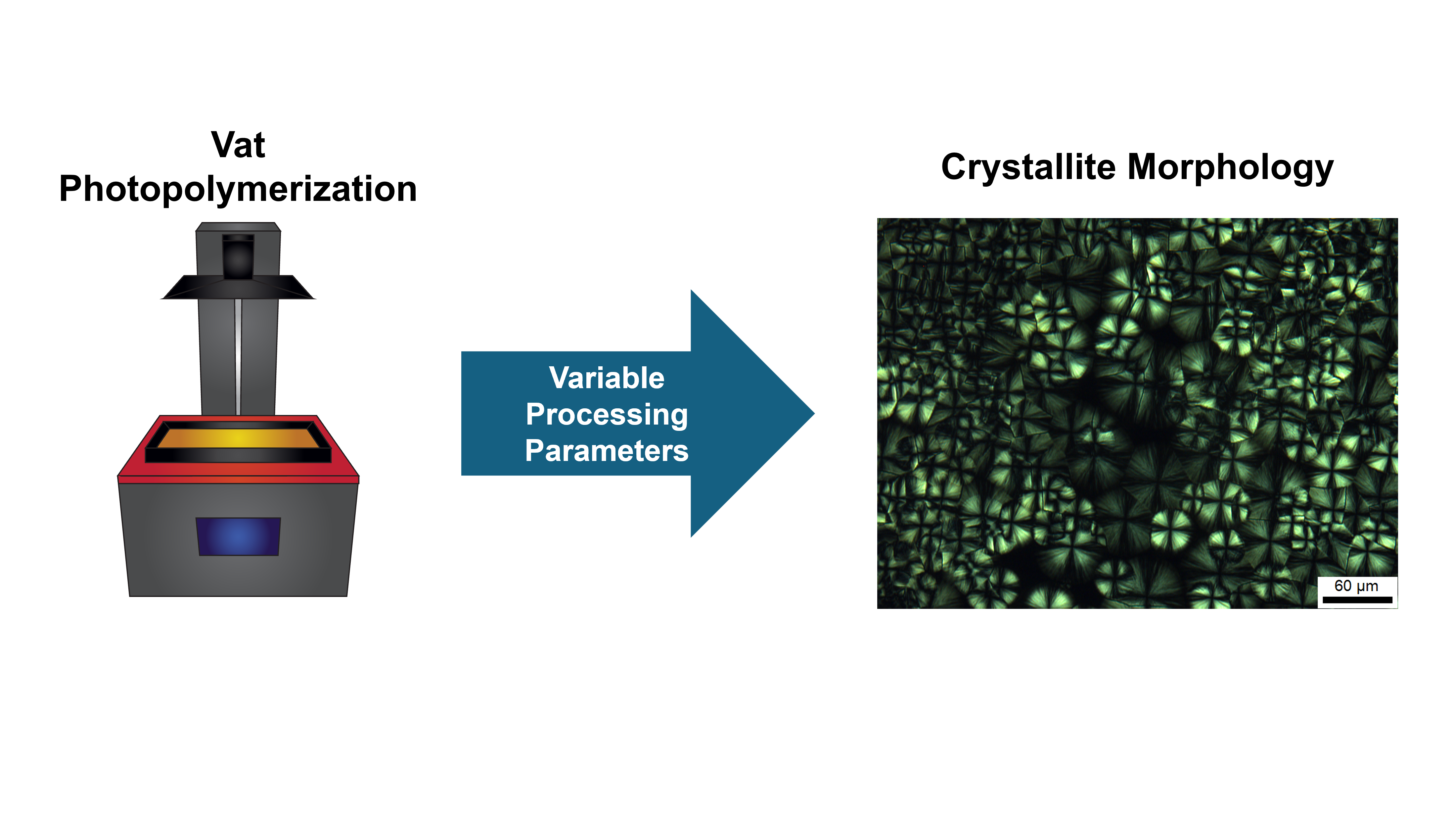

(552h) Effects of Vat Photopolymerization Parameters on Crystallite Size Distribution and Nucleation Rate of a Semicrystalline Polymer

Understanding how processing parameters influence the crystalline morphology of semicrystalline photopolymers is critical for optimizing their performance in vat photopolymerization-based additive manufacturing. In this work, we investigate the effects of light intensity, layer thickness, and photoabsorber concentration on the crystallite size distribution and nucleation rate in a thiol-ene-based semicrystalline polymer system composed of pentaerythritol tetrakis(3-mercaptopropionate) (5 mol%), 1,6-hexanedithiol (90 mol%), and diallyl terephthalate (100 mol%), with Sudan I as the photoabsorber. Polarized optical microscopy (POM), combined with image segmentation techniques, is used to quantify morphological features related to crystallinity, while hot-stage POM is employed to analyze the effects of annealing temperature. Differential scanning calorimetry, tensile testing, and gel fraction analysis are utilized to assess the thermal and mechanical characteristics corresponding to each processing and post-processing condition. Preliminary findings indicate that higher light intensities increase the number of amorphous regions, while greater layer thicknesses promote the formation of multilayer spherulites and larger surface crystallites. Notably, vat photopolymerized samples with higher layer thickness exhibit greater enhancement of material performance after annealing, suggesting a strong correlation between crystallite morphology and bulk properties. These findings advance the understanding of the influence of vat photopolymerization parameters on nucleation, growth, and morphology in semicrystalline polymers, and can provide insights into the design of materials with tunable properties for additive manufacturing.