2025 AIChE Annual Meeting

(17c) Effect of Wettability on Permeation and Flow of Liquid through Filters

Authors

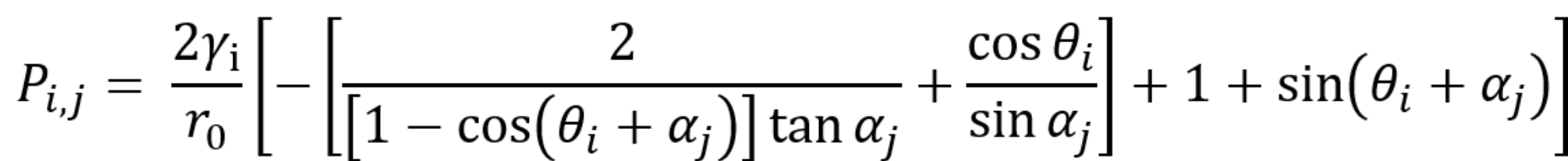

Previously, an equation was developed that enables the calculation of the pressure for a liquid species, i, with its surface tension γi, to permeate through a pore. When the contact angle of species is θi, the wall angle is αj, and the radius of the pore is r0, The pressure for the species to permeate, Pi,j, can be calculated as; (see the attached image)

In our experiments, the liquid height of the same species, i.e., water, was used to provide the pressure. Therefore, the height to permeate, hi,j, can be simply calculated by hi,j = Pi,j/ρg with ρ being the liquid density and g being the gravitational acceleration.

While this equation was verified with a cylindrical hole, the heights to permeate for meshes were not measured. In addition, the flow rates through a cylindrical hole and the meshes were not measured. The hypothesis is that the flow rate would be higher if the height to permeate is lower. In this presentation, we changed the height to permeate, hi,j, with θi to control the flow rate through cylindrical holes and meshes.

To control the θi of cylindrical holes, they were coated with PDMS and the contact angles of water on them were controlled by the time under UV-ozone. The longer the exposure to UV-ozone, the contact angle decreased. The contact angle of meshes was controlled by using four different kinds of meshes; nickel (θi = 50°), copper (θi = 65°), polyester (θi = 80°), nylon (θi = 100°). Their pore sizes were all 50 μm × 50 μm so that only the effect of contact angles was accounted for. Water was added on the cylindrical holes and the meshes, and the flow rates were measured at different heights of water.

With the experiments with cylindrical holes, the decrease in contact angle increased the flow rate at a constant height of water (hydraulic head). This is because the pressure/height to permeate, which works as the resistance for water flow, decreased as the contact angle decreased, as predicted with the equation above. At a certain contact angle, the flow rate increased with an increased height of water (higher hydraulic head). Smaller holes showed less change in flow rate with the change in contact angles. The experiments with meshes also showed an increase in the flow rate with a decrease in contact angles. However, due to low heights to permeate (less than 4 mm) for all species, the difference in height to permeate was not resolved.