2025 AIChE Annual Meeting

(194f) Effect of Catalyst Regeneration Time on Bioethanol Conversion to Sustainable Aviation Fuel (SAF) Using a Newly Developed Hierarchical HZSM-5 Zeolite Catalysts

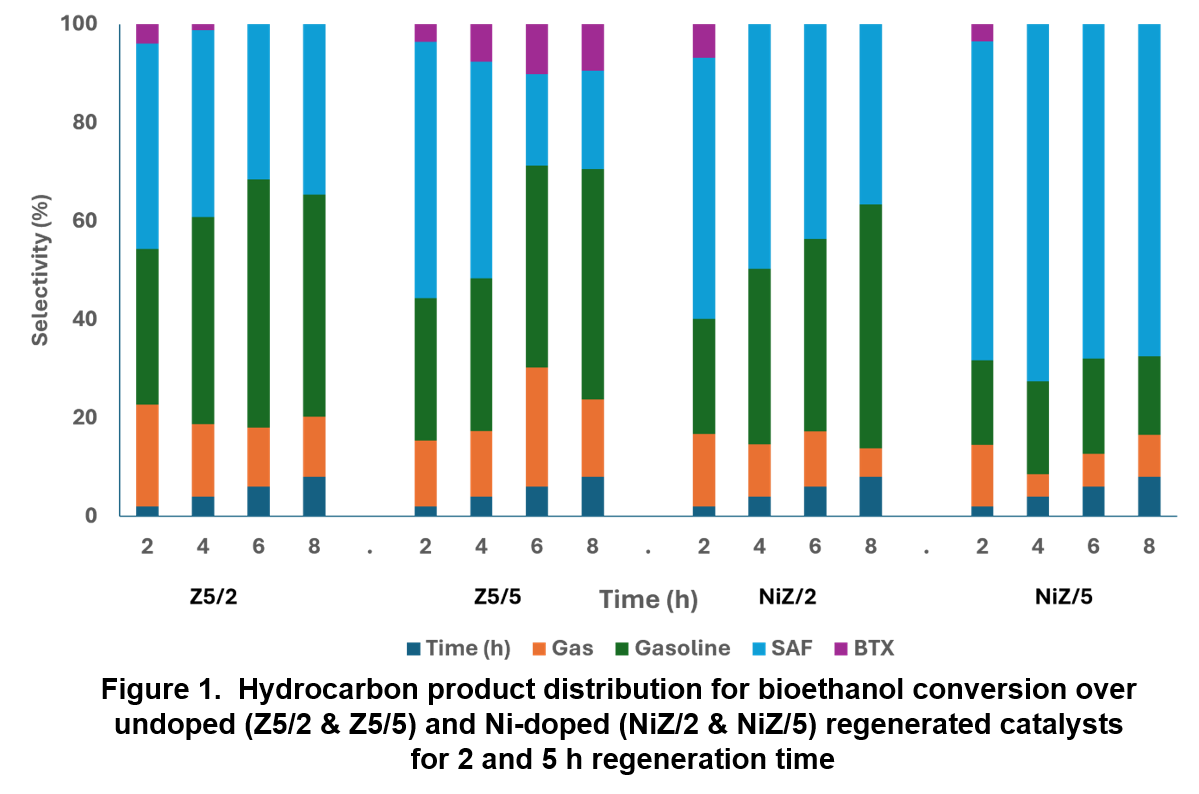

The hierarchical HZSM-5 support was synthesized via hydrothermal synthesis using a batch composition of 10Na₂O, 40SiO₂, 1.0Al₂O₃, 10.5TPABr, and 3740.6H₂O. Nickel (0.5 wt%) was introduced through incipient impregnation. The catalysts were characterized using XRD, FTIR, SEM-EDS, BET, N₂ adsorption, NH₃-TPD, and TGA-DTA. Catalytic tests were performed in a fixed-bed reactor at 350 °C and WHSV of 7 h⁻¹ for 8 hours time-on-stream (TOS). Catalyst regeneration was conducted at 550 °C in 80 mL/min airflow for 2 and 5 hours. The fresh and regenerated catalysts were designated Z5, NiZ, Z5/2, NiZ/2, Z5/5, and NiZ/5, respectively. Product analysis by gas chromatography grouped hydrocarbons into light gases (C1–C4), gasoline-range (C5–C8), and SAF-range (C9–C16) fractions.

Results confirmed successful synthesis and Ni incorporation. Both fresh and regenerated Ni-doped catalysts achieved over 96% ethanol conversion, with NiZ/5 exhibiting over 70% SAF selectivity (Figure 1). However, Ni-doped catalysts experienced faster deactivation due to coke accumulation. In contrast, the undoped Z5 catalyst demonstrated superior stability with over 98% conversion and over 50% SAF selectivity throughout the TOS. Regeneration restored catalyst performance with only a slight reduction in surface area, validating the regeneration strategy.

This study introduces an effective regeneration approach while revealing the trade-off between enhanced SAF selectivity and reduced stability in Ni-doped catalysts, offering insights to guide the development of more robust and selective catalysts for sustainable fuel production.